SuperPVDF

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

oateProducts - Microarray Substrates & Slides - SuperPVDF PVDF Coated Substrate Slides for DNA and Protein Microarray Manufacturing

ArrayIt® has developed an advanced microarray substrate slide coated with a PVDF (Polyvinylidene fluoride) membrane for microarray applications. The 150 µm thick layer of PVDF is bound to an atomically flat glass substrate slide for high precision and uniformity. PVDF is a nice surface for a variety of microarray applications. It provides small printed spots since it is a very hydrophobic surface. When used in conjunction with the SpotWare Colorimetric Scanner, background is extremely low. SuperPVDF makes it possible to to transform your traditional filter PVDF dot blot assays into a microarray format for highly affordable research and in vitro diagnostic applications.

NOTE: These substrates are compatible with AHC1x16, AHC1x24, AHC4x24, RC1x24 well reaction tools to multiplex the number of microarrays per silde substrate. Additionally the gaskets on these tools can be cut to customize the microarray printing and reaction area.

Table of Contents

- Product Description

- Usage Tips

- Printed Microarray Storage

- Blocking and Washing

- Example Protocol

- Short Protocol

- Complete Protocol

- Ordering Information

- Warranty

Product Description

The SuperPVDF surface provides a white micro porous polymer laminated to a SuperClean substrate at an affordable price. The surface binds proteins and other biomolecules through an efficient hydrophobic interaction. Microarrays can made with microarrayers running the ArrayIt® Micro Spotting Device, but other systems can be used. SuperPVDF Substrates are manufactured in class 1 cleanrooms. Cleanroom manufacture eliminates contamination of the microarray surface with particulates, proteases, nucleases and other contaminants that impair the quality of microarray experimentation.

Users will appreciate the following features of SuperPVDF Substrates:

- Manufactured in state-of-the-art class 1 microarray cleanrooms

- Free of particulate, protease and nuclease contamination

- Standard 1” x 3” size (76 x 25 x 1.2 mm including hydrophobic polymer)

- Corner chamfer (upper right corner) for unambiguous orientation

- High efficiency hydrophobic coupling

- Supports all microarray manufacturing methods

- “Zero” background when used with the SpotWare Scanner

- Uniform feature size due to the homogeneity of the surface

- 25 substrates per box

- Anti-static and impact resistant packaging

- Indefinite shelf life at room temperature

SuperPVDF is compatible with most all microarray scanners including the InnoScan Series Scanners, SpotLight Microarray Scanner and the SpotWare Colorimetric scanner. The following detection methods can be used with this surface:

· Fluorescence

· Colorimetric

· Chemiluminescence

· Radioactivity

SuperPVDF substrates are ready to use “right out of the box” without any additional processing or surface preparation. This surface is fully compatible with a variety of manufacturing technologies including ArrayIt® contact printing as well as non-contact printing such as ink-jetting.

SuperPVDF Usage Tips

Printing the Microarray:

Proteins should be spotted in Protein Printing Buffer. If the protein is already in a 1X PBS solution, add an equal volume of printing buffer to achieve a final protein concentration between 0.1 and 2.0 mg/ml.

SuperPVDF is a 150-micron thick layer of polyvinylidene fluoride membrane that has a high binding capacity. When using a Robotic Microarrayer such as the NanoPrint, SpotBot 2 or other microarrayer in conjunction with an ArrayIt Spotting Device, decrease Z-axis speeds to 2 cm/sec to avoid denting the membrane. Because of the hydrophobic nature of this substrate, it is not necessary to keep the dwell times of micro spotting pins to the surface at a minimum. 45 to 65% humidity and ambient temperatures should be used. For best source sample integrity, use a system like the SpotBot 2 or NanoPrint with source plate cooling.

Printed Microarray Storage:

Printed microarrays should be incubated overnight at low humidity to establish the coupling reaction. Refrigeration can be used, but Arrayit printing buffers are designed to stabilize proteins and DNA for long-term storage at room temperature. Vacuum packing can also be used; make sure microarrays are dry prior to vacuum packing. Store printed microarrays unblocked and un-washed, performing blocking and washing steps just prior to incubation or hybridization.

SuperPVDF Reactions, Blocking & Washing:

Prior to performing binding reactions, SuperPVDF should be blocked with SuperProtein blocking buffer for 1 hour and then washed 3 times in 1X PBS for 5 minutes using a high throughput wash station. Do not let the surface dry out between blocking, binding and washing reactions. SuperPVDF should only be allowed to dry after printing and prior to scanning only. Use of an ArrayIt high throughput wash station will ensure success.

Multiplexing Reaction Tools

SuperPVDF slides are compatible with the multiwell reaction tools, AHC1x16, AHC1x24, AHC4x24, and MMH4x24. Using these tools and the right microarrayer programming it is possible to run up to 24 separate microarray experiments on a single slide.

Scientific Publications

Click here for recent scientific publications using ArrayIt® brand SuperPVDF Microarray Substrates slides from Arrayit International, Inc.

Example Protocol:

Assay for Detection of Antibodies to Target Antigens Printed to the SuperPVDF slide substrate:

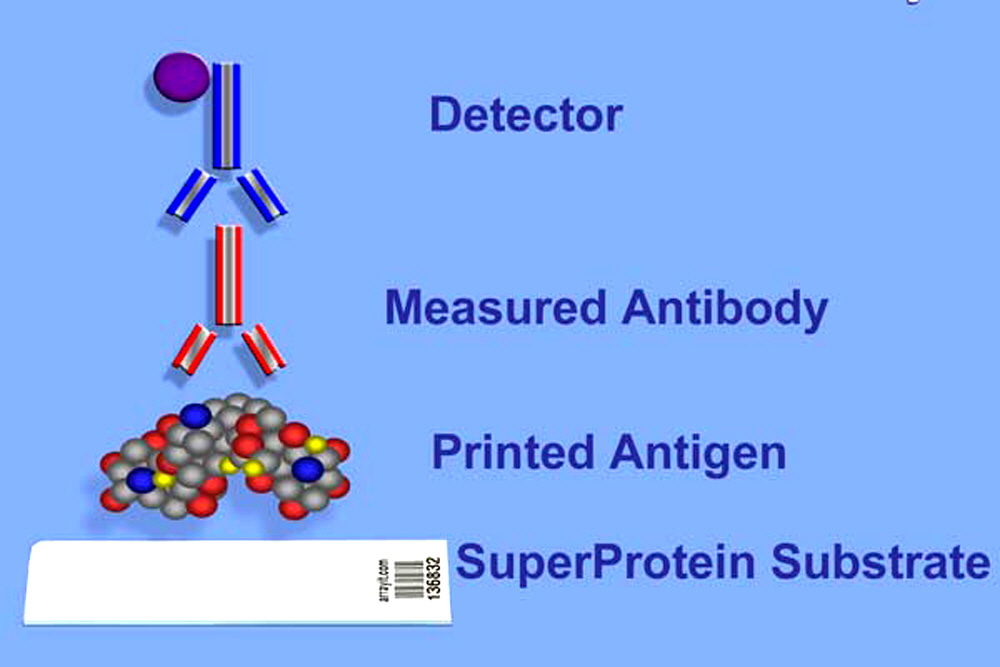

Figure 1. Antigens can be printed on SuperPVDF surface. Patient serum containing measured antibody is incubated to the microarray. After reaction a secondary antibody containing enzyme linked conjugate is incubated and subsequently developed to allow colorimetric detection of the measured antibody. The use of an incorporated internal calibration curve for each subclass of antigen/antibody on the microarray provides a unique advantage over current immunoassays protocols, where the standard curve and the sample are processed in separate tubes or wells.

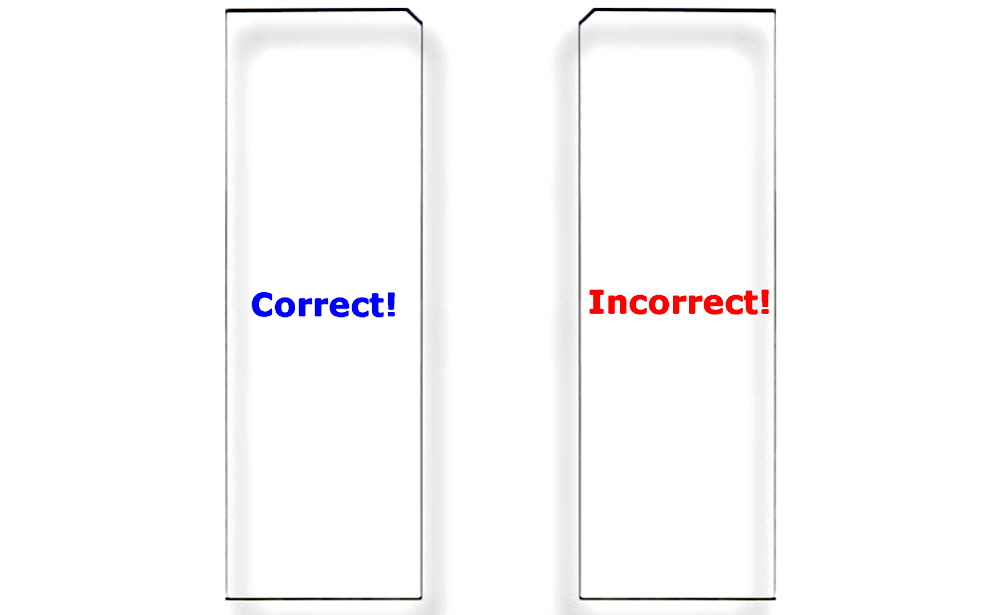

Figure 2. Correct Substrate Orientation. Shown is a graphic of two ArrayIt® Microarray Substrates, showing the correct and incorrect orientation for use. In the correct orientation (blue graphic), the chamfer will be located in the upper right corner and samples should be printed on the side facing upward, which is the same side that contains the word “Correct!”. In the incorrect orientation (red graphic), the chamfer will be located in the upper left corner, placing the backside facing upward, which is the side that contains the word “Incorrect!”. Only one side of ArrayIt® Microarray Substrates is suitable for printing. Please print on the correct side only.

Short Protocol:

- Print biomolecules into a microarray using a SpotBot Protein Edition Microarrayer, NanoPrint or other suitable microarray printer.

- Wash using PBS and Block using SuperProtein Blocking Buffer.

- Perform binding reaction.

- Wash with PBS.

- Perform reaction with secondary labeled conjugated antibody.

- Wash.

- React detection reagents (colorimetric, fluorescent, chemiluminescent)

- Scan with SpotWare, SpotLight or Innoscan series microarray scanners (or other suitable slide based microarray scanner) and analyze the microarray.

Complete Protocol:

1. Print purified proteins suspended in PBS at 0.1-1 µg/µl as a final concentration from an MMP384 microplate with no more than 15 µl per well with a SpotBot Protein Edition Microarrayer, NanoPrint Protein Microarrayer or compatible device. A 50kD protein at 1 µg/µl concentration has a concentration of 20 µM. Assuming a 30% coupling efficiency, a 20 µM protein will produce a target density of 1011 proteins per mm2 of substrate. Proteins retain binding and enzymatic activity on the surface. Printed microarrays should be stored unprocessed at 4C to protect coupled molecules. Processing should be performed just prior to use for best performance.

2. Wash printed microarrays by adding 400 ml of 1X PBS in a High Throughput Wash Station and wash with gentle agitation for 15 minutes. Remove printed microarray and spin dry for 10 seconds using a Microarray Centrifuge. Using 4 ul for every square centimeter of coverslip of SuperProtein blocking buffer and incubate for 1 hour and then wash for 5 minutes with PBS using a High Throughput Wash Station and spin dry.

3. Perform binding reactions in blocking buffer plus primary antibody or control sample diluted 1:1,000. Samples can be incubated as a droplet on the printed microarray, underneath a cover slip, or in a micro-fluidics chamber. A 60-minute incubation at room temperature is usually sufficient to obtain a strong signal. Reactions are also performed by pipetting 10 L defined volume of sample or control (primary antibody) into Petri dish in 10 ml of blocking buffer.

4. Appropriately discard the reaction sample or control solutions and wash the slides in 1X PBS, 3 times at 10 minutes each in a High Throughput Wash Station.

5. React microarray with an enzyme conjugated labeled secondary antibody for 1 hour (e.g. goat anti-human IgG-AP). Use a dilution of 1:1000. Samples can be incubated as a droplet on the printed microarray, underneath a cover slip, or in a micro-fluidics chamber such as the TrayMix. A 60-minute incubation at room temperature is usually sufficient to obtain a strong signal.

6. Wash away secondary antibody using High Throughput Wash Station and 1X PBS, 3 times for 10 minutes each.

7. Use appropriate enzymatic developer for colorimetric detection. For quantitative work, pre-determine development time by conducting pilot study. It is important that all microarrays to be compared are developed by the same time procedure. It is not always necessary to see signal by eye, the SpotWare Colorimetric Microarray Scanner can detect signals that are invisible to the naked eye.

8. To stop further color development, immerse the microarrays in distilled water 2 minutes. Spin the slides dry in an ArrayIt Brand Microarray Centrifuge. Microarrays are now ready to scan in the SpotWare Colorimetric Microarray Scanner. Fluorescent based detection systems use a SpotLight or Innoscan series microarray scanner.

ArrayIt® SuperNylon Microarray Substrates represent a highly innovative membrane surface for researchers wishing to utilize the time-tested attributes of positively charged nylon membranes in a microarray format. SuperNylon can be used to attach DNA, protein, carbohydrate and any other molecule that has been shown to bind nylon in traditional filter assays. The high binding capacity of the 150 µm nylon layer is complimented by a polished atomically flat glass substrate for optimal performance compatibility with all standard glass substrate slide microarrayers and scanners.

Scientific Publications

Click here for recent scientific publications using ArrayIt® brand SuperPVDF Microarray Substrates from Arrayit.