Microarray Pins Stealth Technology

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Stealth microarray manufacturing contact printing spotting pins printheads SMP3 life sciences research

Arrayit has set the standard for microarray manufacturing since 1997. ChipMaker, Stealth, 946, and Professional microarray pins and printheads are patent protected technologies (U.S. 6,101,946) that represent the most advanced and widely used microarray technology in the world with >3,000 installations. Users can choose among dozens of different spotting pin designs and sizes, and all ArrayIt® 946 and Stealth microarray printing pins and printheads are fully interchangeable for maximum flexibility. Shown here is a Stealth 48 printhead fitted with 48 SMP3 microarray spotting pins.

Click here for 946 style microarray spotting pins with extended collar design.

Why Stealth is such a highly advanced microarray spotting technology.

The patented Stealth contact printing technology from Arrayit uses short Pins and a single-guiding surface Printhead, for superior durability and precision.

Pins ride up and down in a 10 µm “air bushing” in the Printhead guiding holes, providing near frictionless printing and millions of printing cycles without any detectable wear. Pins and Printheads maintained properly will last for years, even with regular use.

Pins are available in a wide assortment of tip and channel sizes, allowing users to specify spot diameter and loading volume.

Microarray Spotting Pins and Printheads are manufacturing using the world’s most advanced micro-machining technology, ensuring tolerances in the range of ±0.0001” (2.5 µm)!

Stealth technology is compatible with any high quality motion control system, allowing users to equip their favorite robot with Stealth. Stealth technology is used with robots made by 20 different companies, and our worldwide placements exceed 1,100. Because many of our customers run core facilities, the total number of individual laboratories using Stealth technology is estimated at >5,000.

All Pins are measured and adjusted digitally, providing perfectly matched Pin sets for uniform spot size from pin to pin.

The Stealth 48 Printhead holds 48 Pins for up to 10 times faster arraying than other contact and non-contact technologies. Motion control systems equipped with a Stealth 48 Printhead and Pins will print 50 chips of 10,000 spots in 6 hours.

The Stealth Printhead allows manual Pin removal and replacement, without any special tools, disassembly, or expensive service calls. A complete set of 48 Pins can be removed by hand in less than 5 minutes, providing a simple and reliable printing technology.

Stealth Pins are equipped with collars that ride freely in the Printhead guiding channels, exploiting gravity to return the Pins stationary position during each Printing cycle. By exploiting gravity and avoiding spring loading, Stealth Pins are durable to millions of cycles. The collars also prevent the pins from rotating during the printing process, increasing the printing accuracy.

Stealth Pins have 4.5 mm center-to-center spacing, allowing the flexibility of loading samples from 96-well (9 mm spacing) and 384-well (4.5 mm spacing) plates. A Micro Spotting device for 1536-well plates (2.25 mm spacing) is under development.

One of the main advantages of microarray technology is the use of small sample volumes. Stealth SMP3 Microarray Spotting Pins have an uptake volume of 0.25 µl and a delivery volume of 600 pl, providing up to 400 spots per loading. Ten complete print runs can be accomplished using only 2.5 µl of sample. A single PCR reaction provides material sufficient to make >1,000 chips.

Other less advanced systems require 3-30 µl of loading volumes.

Stealth Pins have very small sample volumes of 5 µl per 384-well plate, conserving precious array samples.

ArrayIt Brand Stealth and 946 Microarray Spotting Technologies have become the standard in the industry for contact printing of cDNAs, proteins, antibodies, small molecules, PNAs, carbohydrates and many other target types. Our widely used platform makes it easy to collaborate and exchange data with researchers at universities,

companies and clinical laboratories worldwide. All Stealth and 946 Pins and Printheads are fully interchangeable for maximum affordability and user flexibility.

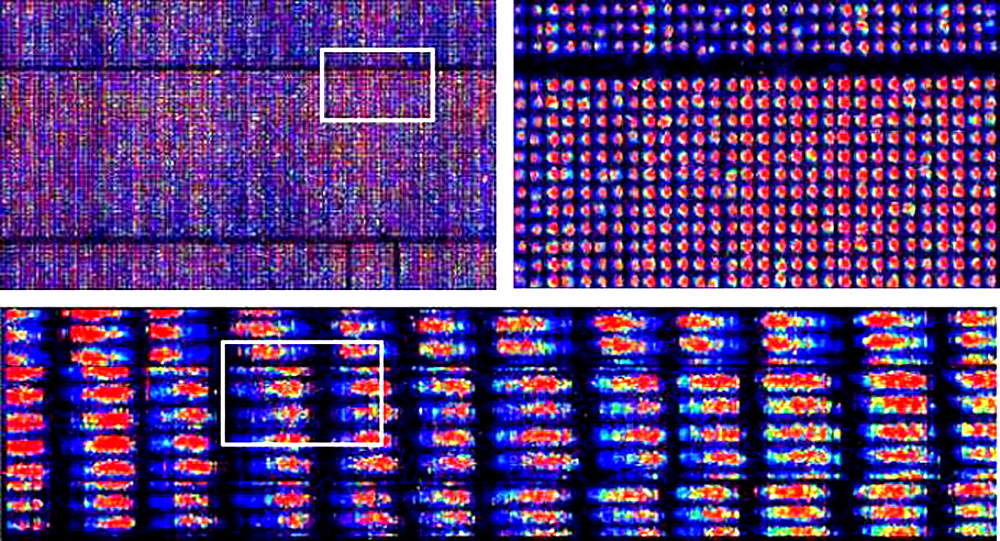

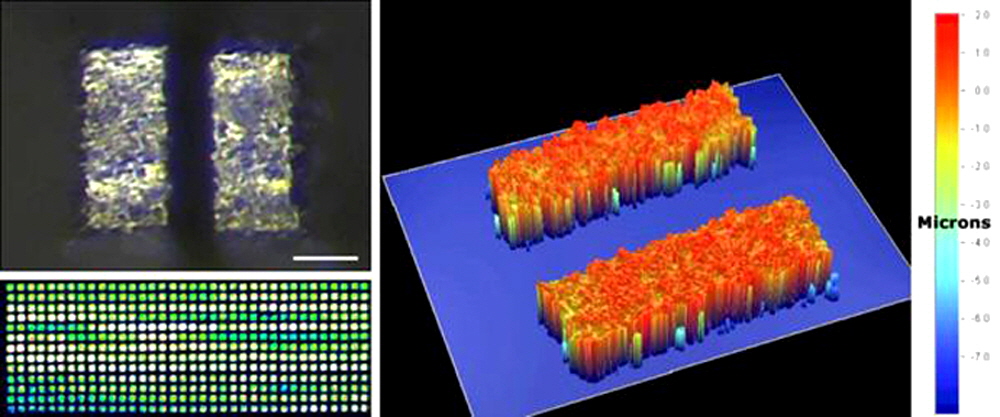

Figure 1. 82K Microarray. Shown is a DNA microarray containing 82,944 spots printed on a treat microscope slide (CEL distributed by Arrayit). The test spotting solution containing 1.0 pmole/µl Cy3-labeled 21-mer oligonucleotide suspended inMicro Spotting Solution, was deposited as 0.4 nl droplets at 120 µm center-to-center spacing with a PixSys 5500 gridding robot (Cartesian) equipped with a Stealth printhead (SPH32) and SMP3 Micro Spotting Pins (Arrayit). The 144 x 576 array (bottom) corresponds to a 18 mm x 72 mm area on the glass surface with enlargements of 3.6 mm x 7.2 mm (top left) and 1.9 mm x 3.6 mm (top right). Fluorescent scanning was accomplished with a ScanArray 3000 (GSI Lumonics) set at 100% PMT and 70% laser power in channel 1. The 16-bit tiff data are presented in a rainbow color palette.

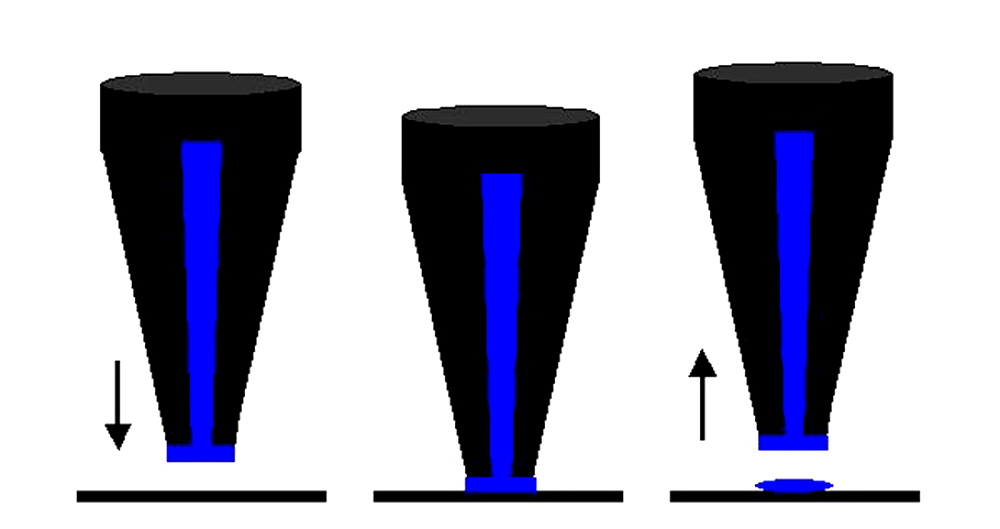

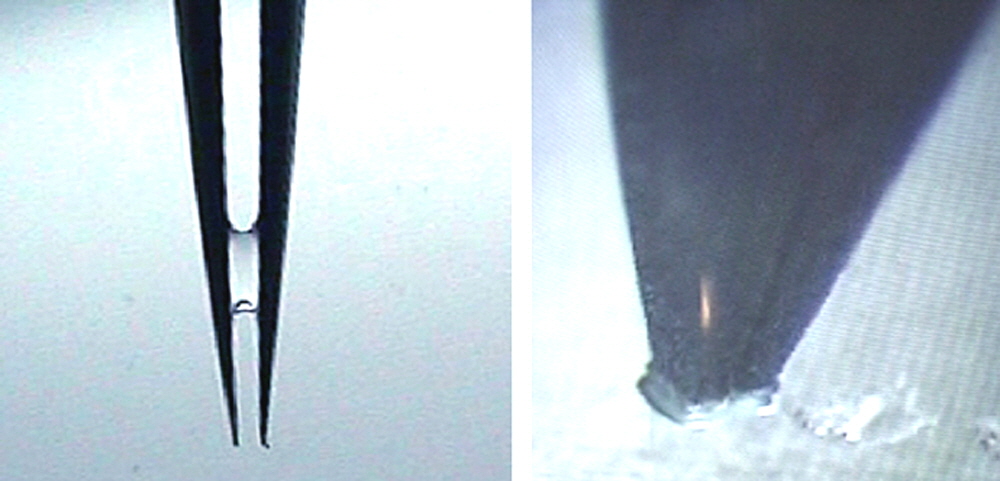

Figure 2. Printing mechanism. Arrayit's unique printing technology (U.S. patent 6,101,946) enables high-speed manufacture of microarrays on glass, gels, membranes and other microarray surfaces. The pins have flat tips and defined uptake channels, which allows a thin (25 µm) layer of sample to form at the end of the pin, and printing to proceed by gentle surface contact. Printing occurs as a simple 3-step "ink-stamping" process as follows: (left) downstroke, (center) contact, and (right) upstroke. Pin tips and channels are available in a wide assortment of dimensions, allowing users to specify spot diameter and the number of spots per loading.

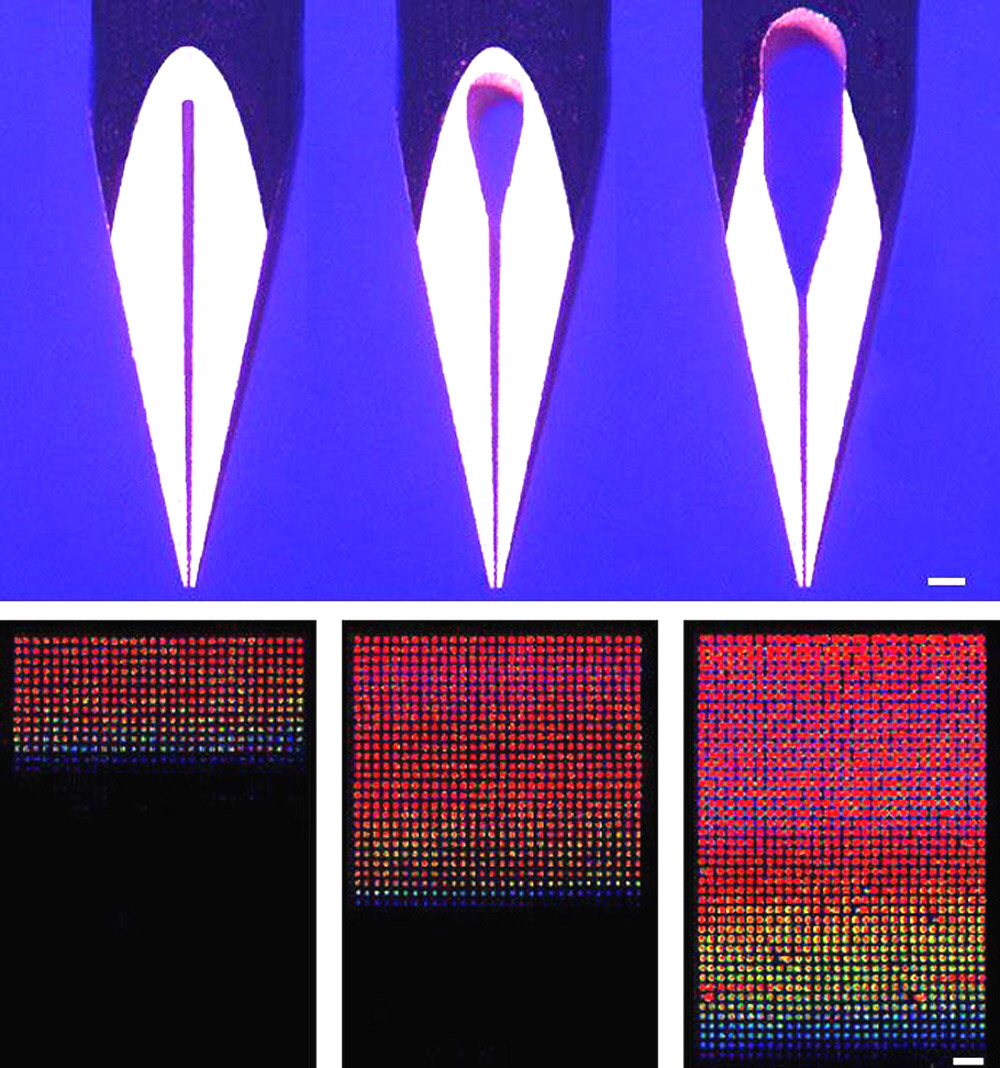

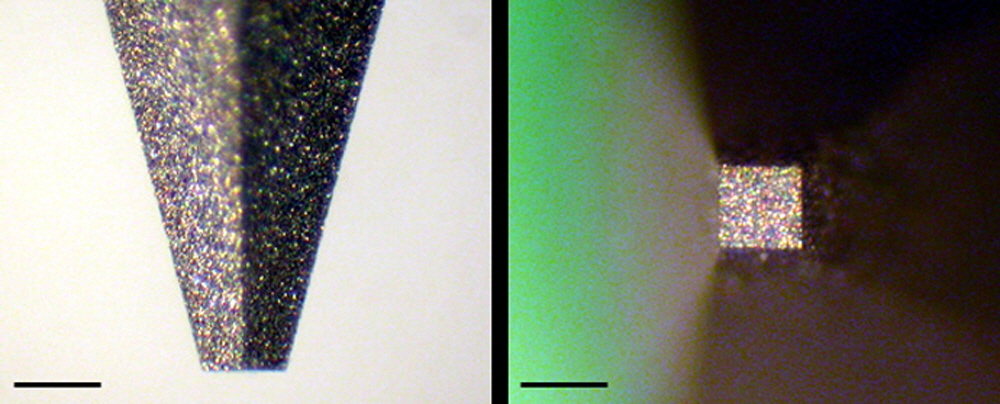

Figure 3. Stealth 3 Pins and Corresponding Microarrays. (Top panel) Shown is an SMP3 Pin with a regular uptake channel (top left), an SMP3B Pin with a "bubble" uptake channel (top center), and an SMP3XB Pin with an "extended bubble" channel (top right). The SMP3, SMP3B and SMP3XB pins load 0.25 µl, 0.60 µl and 1.25 µl of sample, respectively, allowing users to specify loading volumes and the number of spots per loading. The space bar equals 200 µm. (Bottom panel) Microarrays printed with an SMP3 pin (bottom left), an SMP3B pin (bottom center), and an SMP3XB pin (bottom right). The SMP3 pin produces 200 spots of 110 µm diameter, the SMP3B pin produces 510 spots of 120 µm diameter, and the SMP3XB pin produces 780 spots of 130 µm diameter. The sample was a 500 fmole/µl solution of Cy3-labeled oligonucleotide in 1X Micro Spotting Solution (MSS) printed on a SuperAldehyde Substrate (SMA) at 18°C, 50% relative humidity and 150 µm spacing using a PixSys 5500 robot (Cartesian). Printed microarrays were scanned at 80% PMT and 90% laser power on a ScanArray Express (PerkinElmer) and the .tif data were coded to a rainbow palette. The space bar equals 450 µm. A total of 42 interchangeable Stealth pins allow users to specify loading volume, spot diameter, and number of spots per loading (see Table 1). All pins are interchangeable and in the three Stealth Printheads (Table 2) and can be changed manually in a few minutes without any special tooling.

Click here for patent information!

Motion control parameters *

- Non-surface contact: X, Y, Z motions

- Surface contact: Z only!

- Sample loading time: 2-3 sec

- Pin wash time: 3 cycles at 1-3 sec/cycle

- Z axis surface clearance: 1.0-1.5 mm

- Z axis acceleration: 30 cm/sec2

- Z axis velocity: 7.5-20 mm/sec (See Table 1)

- Z axis travel (surface = 0): +0.5-1.0 mm

- Surface dwell time: 0.05 sec

- Cycle time (32 pins): 32 features/sec

*All motion control parameters are suggestions only. Each of these parameters should be empirically tested with a single spotting pin to test printing quality and pin durability. Parameters can be modified to maximize printing quality and speed in a manner compatible with your motion control system. Changes in Z axis surface clearance, acceleration, velocity and travel should be made with extreme care!

How to care for your Stealth Micro Spotting Device

The Stealth Microarray Spotting Device is designed and engineered for optimal wear and durability, while gaining the highest printing performance in the sub-nanoliter scale. The Pins and Printhead have been tested out to 1 million printing cycles with no loss of printing precision or performance. Maximum durability requires proper use. Improper use of these precision products can lead to loss of performance or permanent damage. To avoid damaging your Stealth Micro Spotting Device, please follow these guidelines:

1. The Printhead should be mounted on the motion control system prior to inserting the Pins into the Printhead. All hardware, motion control movements, calibration and software should be completely checked prior to inserting the Pins into the Printhead. Once the Pins are carefully inserted into the printhead, Pins can be damaged by inappropriate use. Pins must never be dropped, slammed or dragged across solid surfaces. Any contact of this nature outside the Z-axis will permanently damage the tips of the Micro Spotting Pins. Pay particular attention to the Z-axis speed settings and use the recommended setting in this protocol.

2. If a loss of printing quality is observed, the spotting pins can be cleaned by carefully by using the Pin and Printhead Cleaning Kit. Never subject Stealth parts to extremes in temperature or pH and avoid the use of strong solvents as these may damage the pin surface chemistry. Never dry Pins using canned air, the propellants ruin the surface tension properties needed for reliable printing. To clean Pins use the Pin and Printhead cleaning kit.

3. Microarray experiments depend upon the quality of the samples. Samples prepared by standard purification procedures can result in pin clogging and a loss of chip quality. For best results with PCR products use PCR products purified with one of the ArrayIt® PCR Purification Kits. Increased performance can also be obtained by using spotting buffers and surface chemistry specifically formulated for optimal results.

4. WARNING: Pressurized air canisters and other sources of pressurized air contain organic propellants that diminish the surface tension properties of pin tips and channels. Do not use pressurized air canisters to dry your pins but rather use the Microarray Air Jet for this purpose.

Notes on wash/dry stations of microarrayers

The keys to a wash/dry station working properly are:

(1) A clean and continuous distilled water source that does not splash or aspirate

(2) Sufficient vacuum airflow to dry the printing mechanisms, and

(3) Proper motion control programming.

Wash water should be continually replenished during a print run to avoid build up of residual sample. A build up of sample could cause serious cross contamination of samples. A vacuum dry station does not rely on vacuum pressure to dry printing tips, it relies on a large amount of air passing over the tips to facilitate drying. Multiple wash/dry cycles are necessary to make sure that all residual samples are washed away. A common error in programming a wash/dry cycle is drying the tips of the printing mechanism too long after the first wash cycle. Only dry completely after the last wash cycle. If any residual sample is on the tip and it is dried there, it is much harder to wash away. The result is poor printing performance and/or cross contamination of sample.

Figure 4. Pin Tips. (Top left) Shown is an SMP-4 pin tip at 335 times magnification (335X) viewed bottom-up along the shaft dimension. The flatness of the tip, which provides the "ink stamp" printing mechanism, is readily observed and the space bar equals 25 microns. (Top right) Surface topology plot of an SMP4 pin tip with data coded to a color palette. Pin tips are flat to about ±2 microns (µm), which allows sample to form at the end of the tip. (Bottom left) Fluorescent samples printed at 100 µm center-to-center spacing with SMP2.5 pins, producing 75 µm spot diameters, 8,100 spots/cm2, and 145,800 spots on a standard 25 mm x 76 mm glass substrate.

Figure 5. Dumont tweezer versus Arrayit Micro Spotting pin.(Left) Tweezers, split pins, and other printing devices that have undefined channels and uneven tips hold sample inside the channel and require a tapping force to break the meniscus and expel the sample onto the printing surface. The requirement of a tapping force greatly diminishes durability. (Right) Arrayit Micro Spotting Pins, by contrast, have defined sample channels and flat tips, which allow sample to form on the end of the tip. Arrayit pins do not require a tapping force to expel the sample, but rather work by a "ink stamping" mechanism. Light contact between the sample or the pin and the printing surface produces highly efficient printing, and durability out to millions of printing cycles. Arrayit pins also print horizontally (inset) and upside down, for greater flexibility in prototyping and research. Arrayit's unique design is covered by United States patent 6,101,946. Please do not infringe our patent.

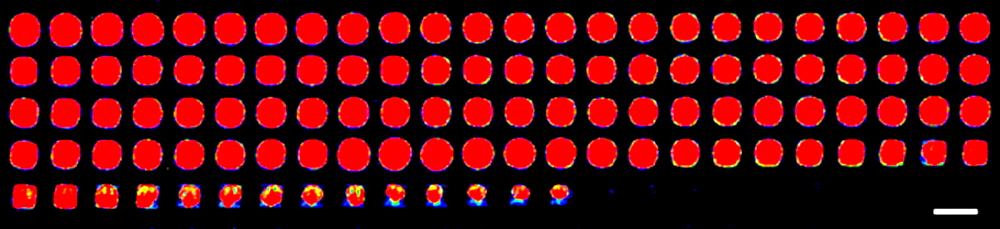

Figure 6. SMP15XB Pin Printing. A 500 fmole/µl solution of Cy3-labeled oligonucleotide in 1X Micro Spotting Solution (MSS) was printed onto a SuperAldehyde Substrate (SMA) at 16°C and 45% relative humidity using a PixSys 5500 robot (Cartesian). Spot spacing was 750 µm. The printed microarray was scanned at 80% PMT and 90% laser power on a ScanArray Express (PerkinElmer) and the .tif data were coded to a rainbow palette. The space bar equals 750 µm. SMP15XB pins load 1.25 µl of sample and print 88 spots of 590 µm diameter under these conditions, and are excellent for diagnostic applications.

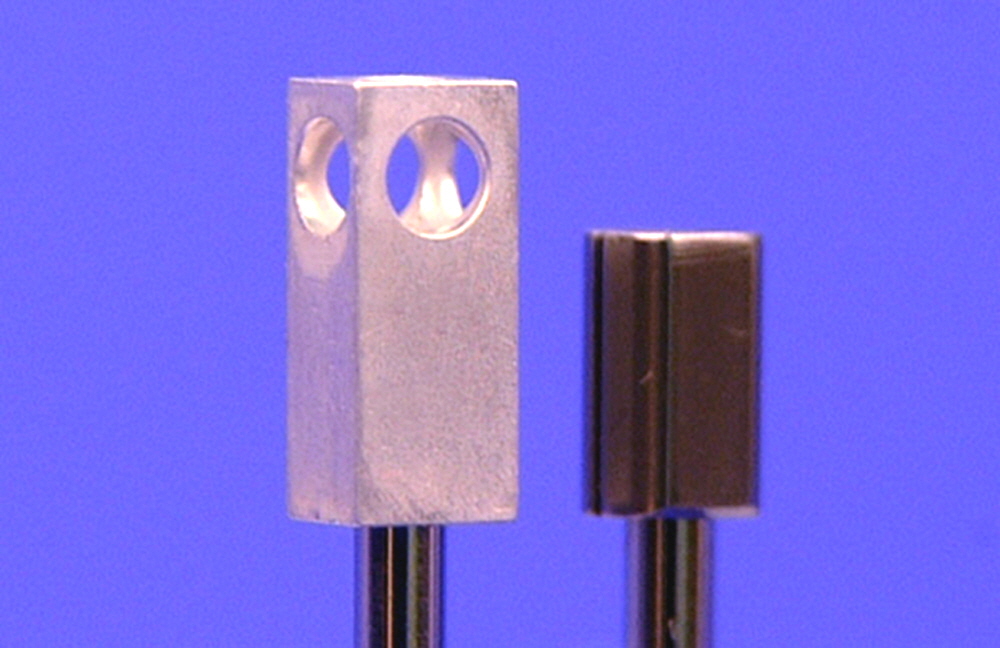

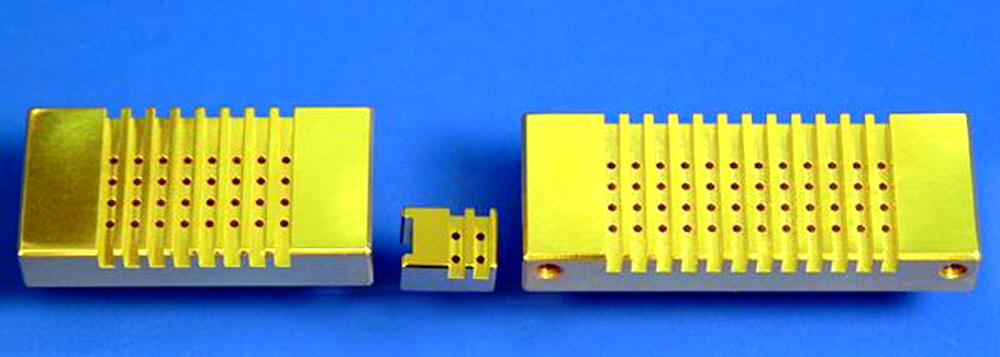

Figure 7. Stealth Printheads. (Left) Stealth 32 Pin Printhead (SPH32) shown as a front view. All 42 Stealth Pins (see Table 1) fit interchangeably in the Stealth Printheads. (Right) Stealth 48 Pin Printhead (SPH48) shown as a rear view. All 42 Stealth Pins (see Table 1) fit interchangeably in the Stealth Printheads. The two mounting screw ports allow easy attachment of Stealth Printheads to any high quality motion control system.

Figure 8. SNS6 Pin Photos. Shown is a Stealth "No Sample Channel" (SNS) Pin with a 0.006" (150 µm) wide tip used for applications requiring solid pins of exacting dimensions. The solid point of the SNS6 Pin is shown as a side view (left) and the tip is shown from the bottom up (right). The space bars denote 150 µm.

Pin and Printhead Cleaning Kits contain all the equipment, tools and reagents for proper cleaning and maintenance of Stealth™ and ChipMaker™ Pins and Printheads. Click here or the photo for more information.

Figure 9. Calibration Pin for Stealth Micro Spotting Device (catalog ID SMPC). This pin doubles as a solid pin for printing large spots, but is best used for calibrating microarrayers. The end of the pin being the same size as the shaft makes it much easier to visualize if the end of the pin is touching off and moving around correctly in and out of microtiter plates, slides/substrates, sonicators and wash stations.

Figure 10. Affordable solid pin compatible with all Stealth and 946 Printheads. Pins are the same length (1 1/16" or 26.99 mm) and have the same shaft diameter as all Stealth and 946 style pins. Pin mass is 0.4 grams and the material is stainless steel. Tip diameter is 0.015" (375 µm) and provides "break away" flexibility for use in testing and calibration microarrayers. These pins can also be use for low to medium density solid pin printing. Catalog number for this product is SSP015.