Microarray Pins 946 Technology

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | 946 microarray manufacturing contact printing spotting pins printheads 946MP3 life sciences research

Tools - Microarray Printing - Microarray Pins 946 Technology

Arrayit has been the industry standard ex-situ microarray manufacturing leader since 1997, empowering customers to manufacture microarrays containing all types of molecules including >100,000 patient DNAs per microarray. Arrayit 946 microarray printing technology has increased Pin and Printhead precision, reduced weight, and proprietary extended collar design, adding up to superior performance and usability. Building on our patented technology (U.S. 6,101,946), we continue to push the envelope to provide our >3,900 installations with the most advanced and innovative contact printing technology available. Pins can be inserted and removed from the Printhead using a manual Pin tool via access holes located in the proprietary Pin collar. This novel design facilitates Pin handling and reduces the chances of tip contamination or damage. 946 style microarray spotting Pins and Printheads are interchangeable with our current Stealth design, allowing users to upgrade their existing systems. 946 microarray printing technology sets a new standard for microarray manufacturing.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Technical Notes

- Motion Control Parameters

- Protocols

- Recommended Products

- Troubleshooting Tips

- Technical Assistance

- Storage Conditions

- Legal Notice

- Licensing

- Ordering Information

- Warranty

Introduction

Congratulations on taking a big step towards improving the affordability, quality and speed of your genomics, biomedical, pharmaceutical and agricultural research. This booklet contains all the information required to take full advantage of Arrayit's ArrayIt® 946 microarray printing technology. For best results use this printing technology with the NanoPrint or SpotBot Microarrayers.

Quality Control

Arrayit takes every measure to assure the quality of our ArrayIt® 946 microarray spotting Pins, Printheads, and accessories. The most advanced micro-machining methods, engineering designs, and space age materials where used in the manufacture of these products. Rigorous digital and optical quality control monitoring of every part at the micron and sub-micron level guarantees that each of these products conform to the highest industry standards.

Product Description

Arrayit's ArrayIt® 946 Micro Spotting Pins, Printheads, and accessories provide the world’s most advanced microarray manufacturing technology available. The technology is ideal for the smallest basic science experiments or industrial-scale microarray manufacturing of oligonucleotide, cDNA, antibody, peptide, and other types of microarrays.

Users will appreciate the following features of the latest ArrayIt® innovation:

- Most advanced, versatile, and affordable microarray technology available

- Near universal usage with >3,900 installations of ChipMaker, Stealth, and 946 and Professional

- Print oligonucleotides, cDNAs, antibodies, antigens, peptides, and more

- Gentle delivery method provides the most robust technology for proteomics

- 15% reduced Pin mass for greater Pin durability

- Reduced Pin mass allows faster printing with small Pin sizes

- Reduced Pin mass allows printing on delicate membrane and gel surfaces

- 5% reduced Printhead weight for less wear and greater motion control precision

- Compatible with new ArrayIt® NanoPrint and SpotBot® Microarray Printers

- Used by all major microarray robot manufacturers

- Novel extended collar “cage” design for easy Pin loading and removal

- Improved Pin shaft dimension for straighter rows and columns

- Improved point centricity for better sub-grid alignment

- Tighter Pin length uniformity allows reduced “travel” distance and faster printing

- Square collar design provides easier Pin inspection and handling

- State-of-the-art packaging using ArrayIt® “sticky box” technology

- Full patent protection afforded by U.S. 6,101,946

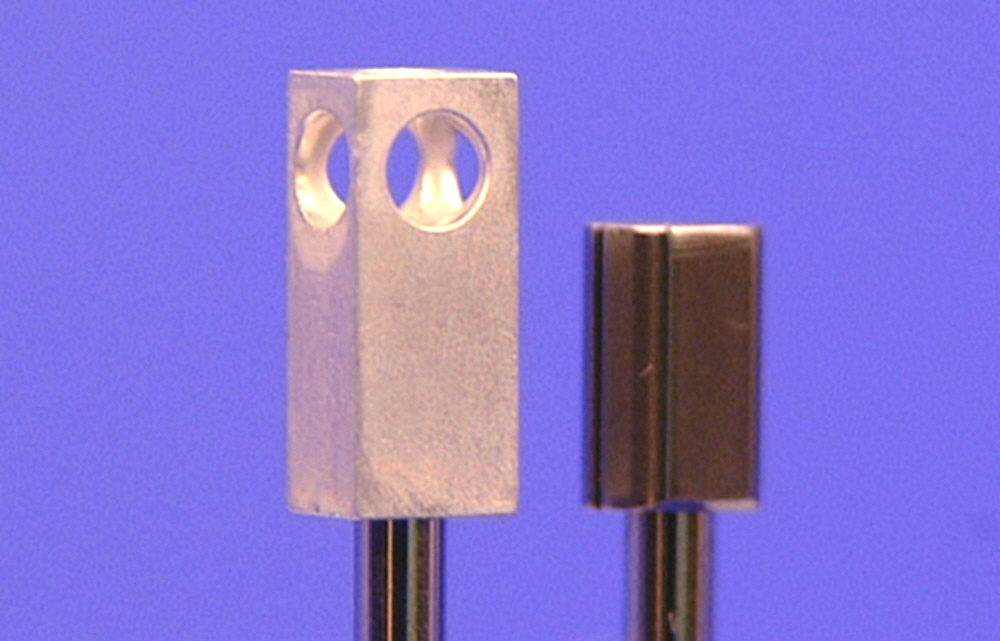

Figure 1. ArrayIt® microarray spotting Pin collars from the most recent 946 printing technology (left) and the predecessor Stealth technology (right). Both collar designs prevent Pin rotation in the Printhead during printing. The 946 style Pins have the added benefit of allowing Pin loading and removal by inserting the Pin tool (946PT) into any of the 4 access ports in the 946 extended collars.

Technical Notes

ArrayIt® microarray printing technology, showcased by our recent 946 product line, has become a nearly universal standard for DNA and protein microarray manufacture. Our installed base of >3,000 customers provides a clear user advantage over other platforms in that we maintain daily contact with a massive customer base, and contacts with a large number of scientists allows us to improve our products and provide superior customer support. ArrayIt® protocols, technical tips, and other forms of feedback empower our customers to perform research at the highest level. Our widely used platform makes it easy to collaborate and exchange data with researchers at universities, companies and clinical laboratories worldwide. The >10,000 scientific publications on microarrays demonstrate the empowering aspects of our technology.

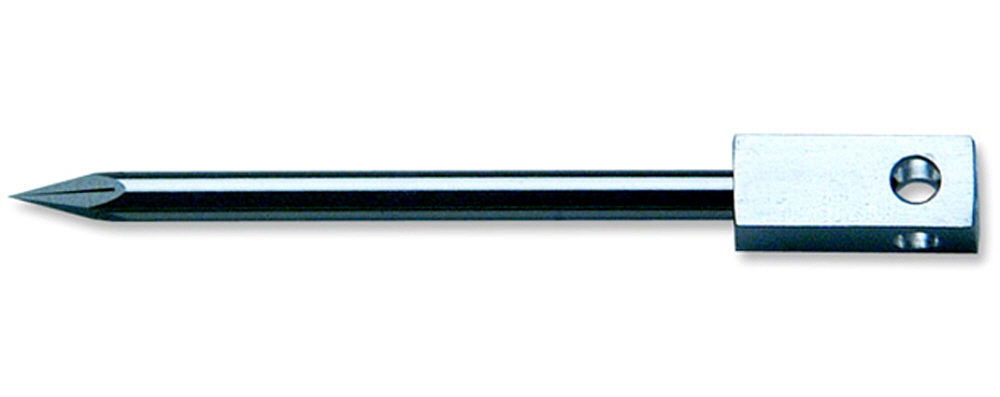

946 style Pins are available in a wide assortment of tip and channel sizes, allowing users to specify spot diameter and loading volume (see Table 1). Pins are available in tip sizes from 0.0015” (37.5 µm) to 0.015” (375 µm) and in sample channel sizes from 0.25 µl to 1.25 µl. Pins with larger tips make larger spots and Pins with smaller tips make smaller spots. Spot size is approximately 30% larger than the physical dimensions of the flat tip with the standard 0.25 µl sample channel, and somewhat larger in Pins containing the 0.6 or 1.25 µl sample channel. A 946 Pin with a 75-µm tip and a 0.25 µl sample channel (i.e. 946MP3) will produce a 100-µm spot. 946 spotting Pins and Printheads are manufacturing using the world’s most advanced micro-machining technologies, with tolerances approaching 50 millionths on certain dimensions. Pins are machined using series-400 stainless steel, allowing remarkable durability lasting millions of printing cycles. Several users have reported “perfect” quality printing with Pins and Printheads purchased from ArrayIt® in 1997, a full six and a half years ago! We continue to use stainless steel rather than harder materials because stainless provides excellent durability and excellent machining quality. Pins made of harder materials produce variable spot size, poor printing efficiency, sample contamination, and a host of other problems, owing to the inability to machine harder materials at high specification. As material science and micro-machining procedures advance, we will incorporate these improvements into our patented technology. At present, the 946 product line is the most advanced technology available.

946 technology was developed to provide an improvement over the earlier Stealth technology, though all 946 Pins and Printheads are fully interchangeable with their Stealth counterparts. New users are encouraged to set up their laboratories using 946, though Stealth and ChipMaker continue to be manufactured and supported by ArrayIt® in the field. 946 is fully compatible with all ArrayIt® microarrayers including SpotBot® and Nanoprint™, as well as robots made by 20 different companies worldwide. The total number of installations of ChipMaker, Stealth and 946 technology is >3,000, making our technology the most widely used microarray platform in the world, serving an estimated 10,000 laboratories.

946 Printheads hold 4, 32, 48 or 64 Pins (see Table 2) at 4.5 mm center-to-center spacing, allowing sample loading from 384-well plates. Motion control systems equipped with a 946 48-Pin Printhead will print 50 chips of 10,000 samples in less than 10 hours. 946 Pins contain an extended collar with 4 access ports, allowing easy Pin loading and removal from the front, both sides, back and top of the Printhead (see Figure 2). This novel “cage” design (patent pending) prevents users from touching the Pin tips, leading to surface contamination and possible damage. The square collar allows easy inspection and handling, and prevents collar rotation in the Printhead for greater printing precision. Pins ride up and down according to gravitational forces, and the avoidance of springs vastly improves printing quality and durability. The ability to easily replace individual Pins or Pin sets allows users remarkable flexibility in the field to control spot size, sample loading volume, and to replace clogged or damaged Pins without expensive service calls. We see this as a major advantage over non-contact technologies that use ‘ink-jets” and other expensive devices that require on-site visits.

Owing to their advanced composition, 946 Pins are 15% lighter than their Stealth predecessors and 54% lighter than ChipMaker Pins. Lighter Pins produce less force on the Pin tip and printing surface for improved performance and durability all the way around. 946 Printheads are 5% lighter than their predecessors. The reduced mass of 946 Pins and Printheads allows greater motion control precision and reduces gantry wear. When combined with the Nanoprint microarrayer, users can control Micro Spotting precision to within an unprecedented 500 nanometers (0.5 µm) for the ultimate printing quality.

An important advantage of microarray technology generally, and 946 technology specifically, is the use of small sample volumes and the creation of high-density formats. 946 microarray spotting Pins load sub-microliter sample volumes, and deliver droplet sizes in the high picoliter and low nanoliter range, producing microarrays with spot sizes of 50-500 µm. A single small-scale oligonucleotide or peptide synthesis reaction or monoclonal antibody preparation provides enough material to manufacture >10,000 microarrays, with sample volumes of 3-5 µl per 384 well. The ArrayIt® Pin printing design conserves precious biochemical samples.

The 946 Printhead should be mounted on the motion control system prior to inserting the Pins. All hardware, motion control movements, calibration and software routines should be tested prior to inserting the Pins into the Printhead. Refrain from dragging Pins across a solid surface or dropping Pins, as this can lead to Pin damage. Pay particular attention to the Z-axis speed settings and use the recommended settings for 946 technology (see Motion control parameters). Remember that light surface contact produces the best microarrays. Tapping is not required to print with ArrayIt® technology. If a loss of printing quality is observed, the most common cause is poor sample loading due to improperly washed Pins. Inspection under a dissecting microscope (20X) can be used to identify clogged Pins. Periodic cleaning by sonication in distilled water usually suffices to restore proper Pin function. The Pin and Printhead Cleaning Kit and Microarray Air Jet are strong recommended for routine 946 Pin and Printhead maintenance.

Avoid exposure of ArrayIt® 946 microarray spotting Pins to extremes in temperature or pH, and avoid the use of strong solvents and corrosive agents as these may damage the Pin surface chemistry. Refrain from drying Pins using pressurized air canisters because the organic propellants in the canned air adhere to the Pin surfaces and impair the surface tension properties needed for proper loading and delivery. Sound microarray experiments benefit from highly purified DNA and protein samples. For best results with PCR products, use ArrayIt® PCR Purification Kits. Superior performance is also obtained using ArrayIt® Printing Buffers and Super Microarray Slide Substrates, which afford microarrays of outstanding quality.

Proper functioning of wash and dry stations is important for microarray printing with 946 Pins and Printheads. The goals are to wash and dry Pins thoroughly to prevent cross-contamination, without impairing the function of the printing mechanism. A clean and continuous source of wash buffer is essential for proper wash station function. Distilled water works well though improved cleaning is obtained using SpotBot Wash Buffer. Is important that the wash station does not splash wash buffer on the underside of the Printhead, as this malfunction will cause Pins to seize and corrode the Printhead. Vacuum or forced air can be used for Pin drying, though such sources must be free of particulate and oily contaminants. Most commercial microarrayers including the SpotBot® and NanoPrint™ microarray printer product lines are equipped with high quality wash and dry stations. A good guide to proper Pin cleaning is to use 3-5 short (0.5 sec) wash/dry cycles followed by 1 longer cycle (3-10 sec) for the final cycle. Properly cleaned Pins must be free of the previous sample and dried completely for efficient loading. The Megasonic Wash Station offers extremely efficient Pin surface cleaning at the atomic level, and is a recommended wash station component.

ArrayIt® microarray printing technology, showcased by our recent 946 product line, has become a nearly universal standard for DNA and protein microarray manufacture. Our installed base of >3,000 customers provides a clear user advantage over other platforms in that we maintain daily contact with a massive customer base, and contacts with a large number of scientists allows us to improve our products and provide superior customer support. ArrayIt® protocols, technical tips, and other forms of feedback empower our customers to perform research at the highest level. Our widely used platform makes it easy to collaborate and exchange data with researchers at universities, companies and clinical laboratories worldwide. The >6,500 scientific publications on microarrays demonstrate the empowering aspects of our technology.

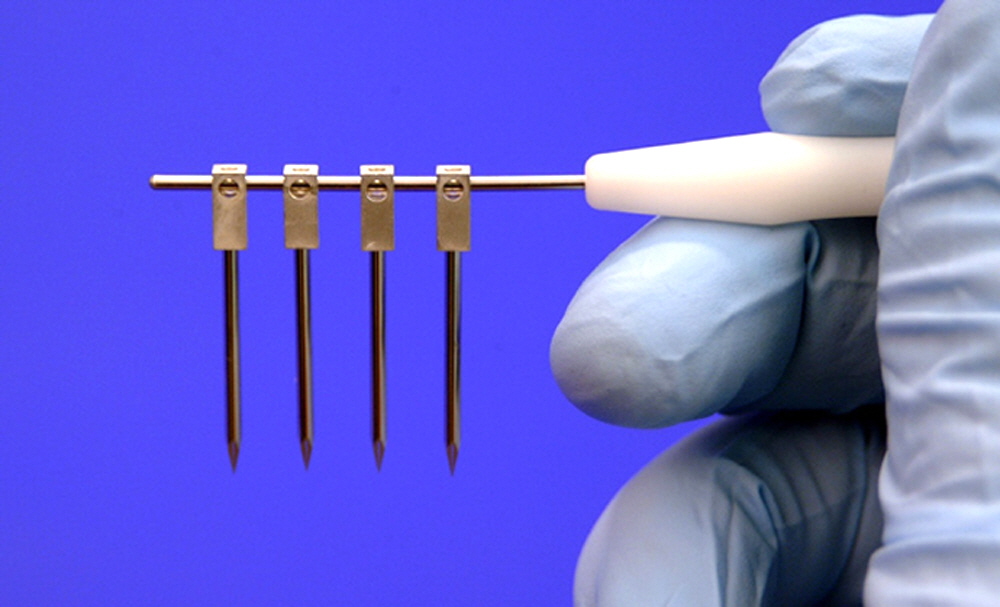

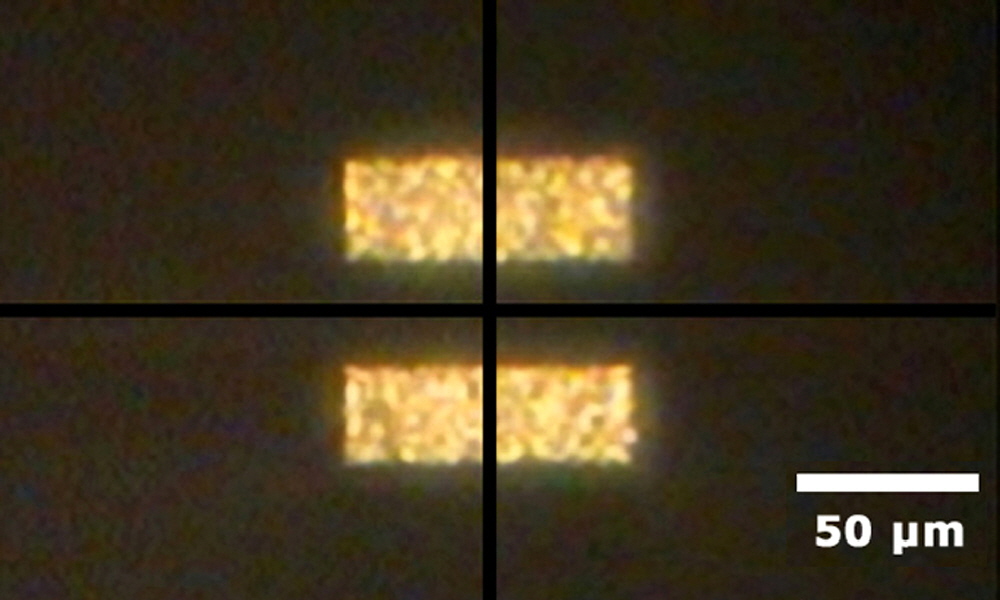

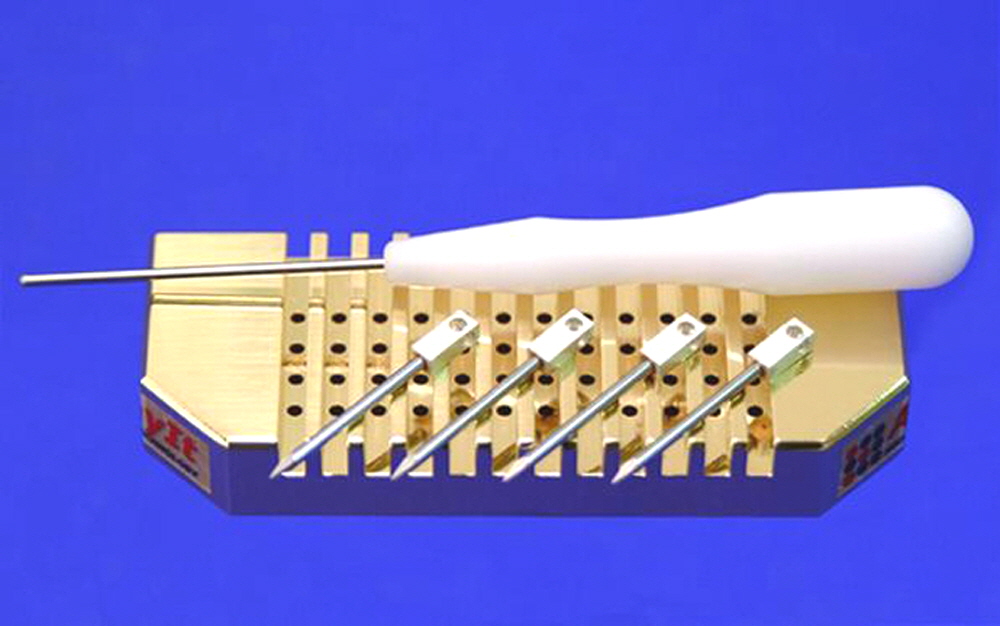

Figure 2. ArrayIt® microarray spotting Pins suspended by the insertion of the Pin Tool (catalog 946PT) into the access ports located in the top of the Pin collars. This proprietary collar design allows easy Pin loading and removal without touching the Pin shafts or points, which prevents contamination and tip damage. Shown here are four 946 Pins with 0.004” (100 µm) wide tips and 0.25 µl uptake channels (catalog 946MP4). The Pin tips are shown at 200X magnification in Figure 4. The 946 Pin Tool can be ordered separately (see Table 3).

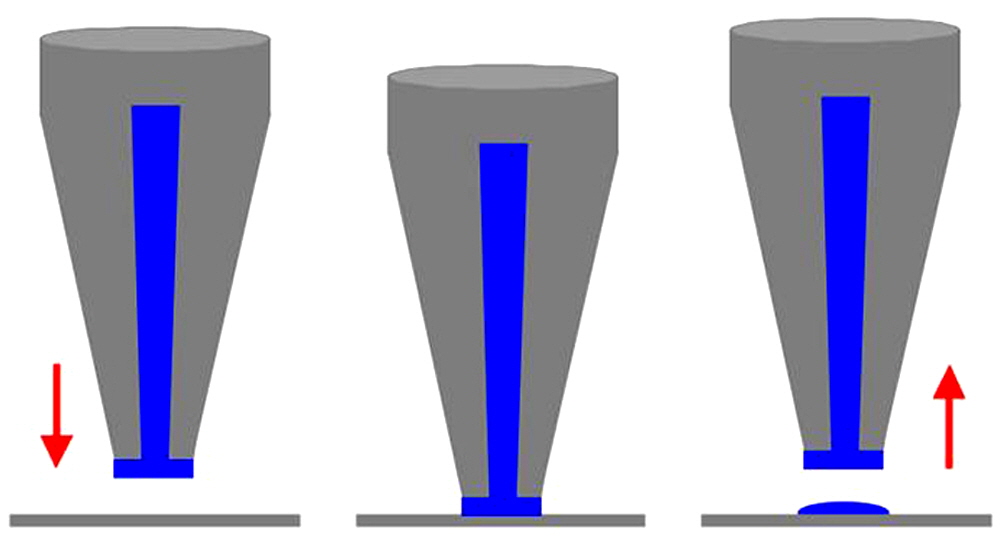

Figure 3. The 946 printing mechanism exploits surface tension and adhesion, as in the earlier ChipMaker and Stealth technology. Sample (blue) loads into the Pin (gray) by capillary action, filling the exterior sample channel completely to provide a pre-determined loading volume (left panel). The horizontally level (flat) tip allows a thin layer of sample to form at the end of the tip, which contacts the printing surface (center panel) during the printing down-stroke, producing a droplet “tug-of-war” between the substrate and the Pin. As the Pin travels upward (right panel), the strong adhesive forces of the substrate pull the droplet off the end of the Pin, leaving behind a perfectly printed microarray spot. Because sample is present at the end of the tip, the ArrayIt® printing mechanism does not require a tapping force to expel the sample. Printing occurs by a gentle “ink stamping” mechanism, greatly extending Pin durability.

Figure 4. Tips of 946 style Pins are horizontally level (flat), allowing printing without the use of a tapping force. In the standard 946-Pin design (shown), the exterior sample channel bisects the Pin completely. In soon-to-be released designs, the exterior sample channel is a groove that runs around the perimeter of the point of the Pin. The space bar corresponds to 0.004” (100 µm), the width of 946MP4 style Pins (see Table 1). The photograph was taken at 200X magnification with a digital photomicroscope.

Motion control parameters*

- Non-surface contact: X, Y, and Z motions are permitted

- Surface contact: Z (up and down) motions only

- Sample loading time: 2-3 sec

- Pin wash regime: 3-5 cycles at 0.5 sec/cycle and 1 cycle at 10 sec/cycle

- Z-axis surface clearance (atomically flat glass, calibrated platen): 0.5-1.0 mm

- Z-axis acceleration: 30 cm/sec2

- X and Y-axis velocity: 5-30 cm/sec2

- Z-axis velocity: 0.85-2.0 cm/sec (See Table 1)

- Z-axis dwell distance (surface = 0): +0.25 to +0.5 mm

- Surface dwell time: 0.05 sec

- Max printing speed (48 Pins): 144 features/sec

*All motion control parameters are suggestions only. Each of these parameters should be empirically tested with one 946 spotting Pin to test printing quality and Pin durability. Acceleration curves, printing substrates, platen composition, and other factors will affect printing speed and Pin durability. Parameters can be modified to maximize printing quality and speed in a manner compatible with your motion control system. Changes in Z-axis surface clearance, acceleration, velocity and travel should be made with extremecare. Arrayit is not responsible for Pin or Printhead damage due to improper programming or motion control settings.

Protocols

Protocol 1. Standard printing procedure using 946 printing technology.

- Program the robot using the graphical user interface. Create a printing routine by specifying the number of plates, number of substrates, number of Pins, center-to-center spot spacing, number of replicates, wash and dry parameters, and other printing criteria. The ArrayIt® SpotBot and NanoPrint™ systems include intuitive controller software that allows mouse-driven creation of printing routines.

- Run the robot without Pins to assess proper clearance. Initiate the print run, allowing the gantry to move to every position on the platen. Run the robot for 20-30 minutes, watching carefully to make sure that the Printhead clears every location on the platen by approximately 1 inch (2.5 cm). This pre-printing check ensures that there is proper clearance between the Printhead and all of the hardware on the deck. Failure to assess proper clearance prior to printing may lead to damaged Pins and Printhead.

- Insert 946 Pins into the Printhead. Using the Pin tool, carefully insert the 946 Pins into the Printhead. The different 946 Printheads hold 4, 32, 48 or 64 Pins. Make sure that the number of Pins loaded corresponds with the number of Pins selected in software. Insert the Pins straight into each hole in the Printhead, making certain not to place lateral force on the Pin tip or collar. Alternatively, the Pins may be inserted manually without the use of the Pin tool. When loaded properly, the bottom of each Pin collar should rest directly against the top surface of the Printhead channel.

- Load samples at 3-5 µl per 384-well microplate. Using a pipette or liquid handling robot, transfer 3-5 µl of each sample into the wells of a 384-well plate. The nominal concentration for printing cDNAs and proteins is 0.25-0.5 µg/µl, and 30-50 µM for oligonucleotides and peptides. Plates should be spun prior to printing to make sure that the sample is located in the bottom of each well. The round wells, conical bottoms, and polypropylene construction of Microarray Microplate 384 make these the plates of preference for microarray printing. Load the plates containing samples into the correct position on the microarrayer platen.

- Place microarray slide substrates onto the robot platen. ArrayIt® offers a complete line of atomically flat microarray slide substrates with reactive organic groups, reflective backside coatings, and membrane coatings to bind the biomolecule of choice. SuperAmine, SuperAldehyde, SuperEpoxy substrates have reactive amine, aldehyde and epoxy groups, respectively. MirrorAmine, MirrorAldehyde, and MirrorEpoxy have reactive amine, aldehyde and epoxy groups, respectively, and a highly reflective backside coating for 2-10 fold enhanced signals. SuperClean is atomically flat glass cleaned at the atomic level, allowing users to supply their own chemistry or perform high-density in situ synthesis. MirrorClean is identical to SuperClean, except that MirrorClean has a highly reflective backside coating. SuperAvidin and SuperStreptavidin have avidin and streptavidin proteins covalently attached to the glass surface, for high affinity binding of biotin-labeled nucleic acids, proteins and small molecules. SuperProtein and SuperNitro are glass substrates coated with hydrophobic membrane and nitrocellulose, respectively, for users wishing to perform membrane-based experiments in a microarray format. Users should match their choice of substrate with each microarray application. Prior to printing, make sure each substrate is seated properly against the base of the platen in the correct location. Substrates not placed securely in position can damage Pin tips.

- Run the printing routine. Make certain the wash/dry station and environmental control are working properly. Standard microarray printing conditions are 45-55% humidity and 20°C. Reduced humidity and elevated temperature will accelerate sample evaporation and should be avoided in most cases. Run the robot until each plate has been printed. After printing, the microarrays can be inspected by light microscopy (20X) to make sure each element has been printed. Some robots allow “cherry picking” and the replacement of select samples that failed to print during the print run. Remove the printed microarrays either immediately or after a 2 to 12-hour incubation in cases where molecular coupling requires a dehydration reaction (e.g. SuperAldehyde). Printed microarrays should be stored in a slide box either at room temperature or 4°C. Vacuum packaging using the VacuSeal™ Microplate System is recommended for extended storage, and microarrays stored in this manner usually retain full activity 1-2 years after manufacture.

- Clean Pins periodically. The 946 microarray spotting Pins should be cleaned periodically to remove trace contaminants that may reduce printing efficiency. The Pin and Printhead Cleaning Kit is highly recommended for Pin and Printhead maintenance. Pin sonication for 10 minutes in distilled water usually suffices for routine Pin cleaning. Sonication for 10 minutes in 1X Micro Cleaning Solution, followed by exhaustive washes and sonication in distilled water, will remove stubborn contaminants. The most common cause of Pins seizing in the Printhead is Printhead corrosion, which is easily removed using the Pin and Printhead Cleaning Kit. Pins and Printheads should be dried completely with a Microarray Air Jet prior to storage or reattachment onto the robot.

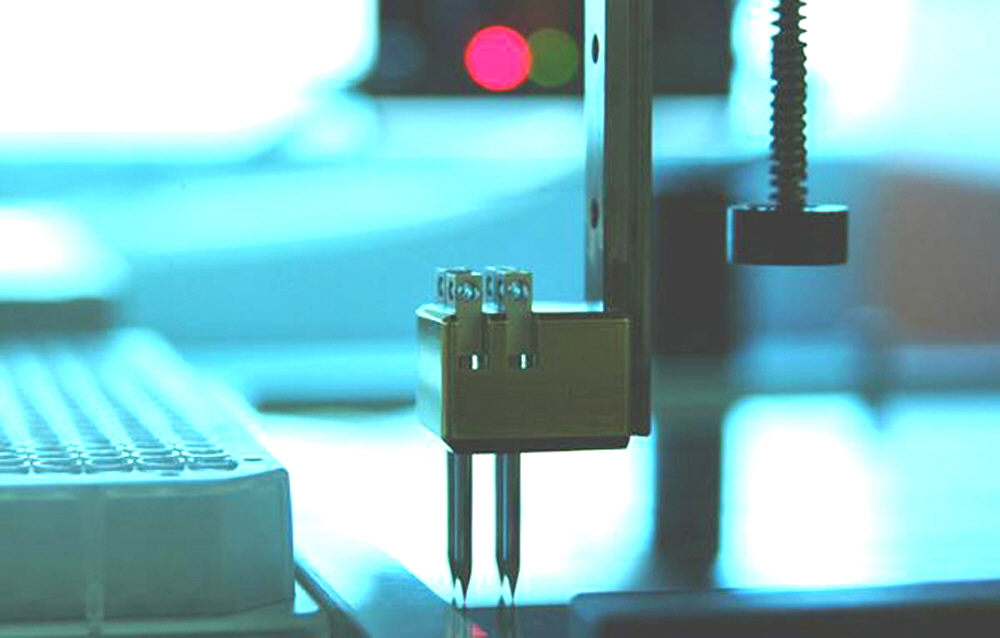

Figure 5. The 946 Pin Tool (946PT) is being used to manually lift and remove a 946MP4 Pin from a SpotBot® Printhead. The access ports in the collar allow Pin lifting from 360°. This novel design minimizes Pin contamination and prevents damage during Pin insertion and removal. Our revolutionary collar design (patent pending) is available with 60 different tip dimensions and channel sizes (see Table 1).

Recommended Products

Our 946 microarray printing technology is best used in conjunction with our ArrayItTM product line. Here are some recommended products that work well with 946:

- SpotBot 2 Microarray Printer

- NanoPrint Microarray Printer Spotter

- Microarray Microplate 384

- Pin and Printhead Cleaning Kit

- Microarray Air Jet

- SuperAmine

- SuperAldehyde

- SuperEpoxy

- SuperClean

- SuperStreptavidin

- SuperNitro

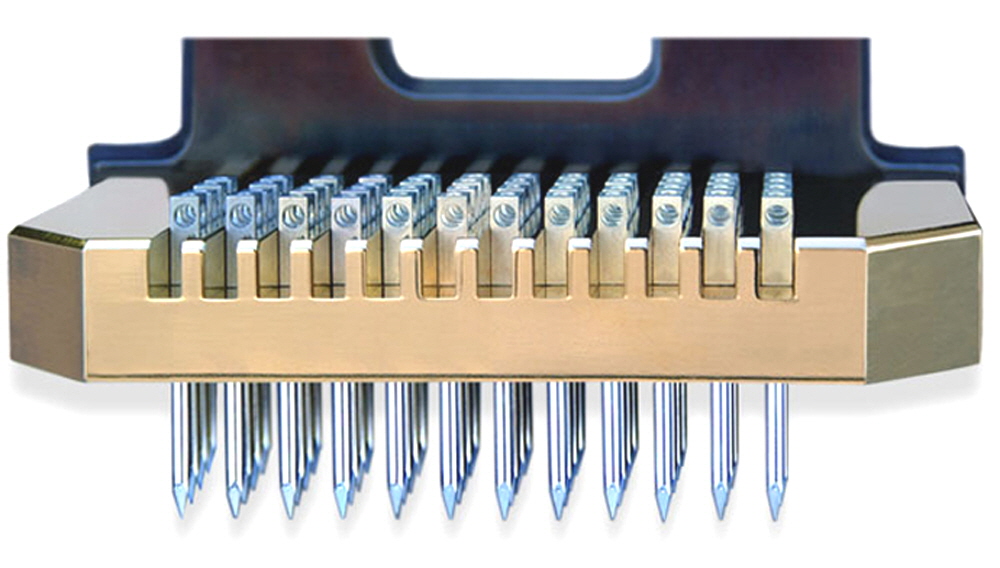

Figure 6. SpotBot® 3 Personal Microarrayer equipped with 4 Pins (946MP4) is shown during the printing process. The bottom of the proprietary square collar lifts off the Printhead during the down-stroke, allowing easy calibration. The four access ports in the Pin collar allow easy Pin insertion and removal. All 946 style Pins and Printheads are compatible with the earlier Stealth design for affordable upgrading. See Tables 1-3 for ordering information.

Troubleshooting Tips

Pins fail to guide smoothly in the Printhead

- Pin shafts are contaminated. Use Pin and Printhead Cleaning Kit

- Printhead is soiled or corroded. Use Pin and Printhead Cleaning Kit

Pins fail to print properly.

- Pins are soiled or clogged. Make sure wash and dry station are functioning properly. Use Pin and Printhead Cleaning Kit to remove contaminants.

Figure 7. 946 style microarray spotting Pins are shipped in our state-of-the-art shipping boxes (Cat. 946SB). These “sticky boxes” use a revolutionary adhesive film that employs Van der Waals interactions to tether each Pin in place, without transferring any organic material (adhesive) to the Pin surface. Sticky boxes are superb shipping and storage boxes for a variety of implements and applications, and can be purchased separately (see Table 3). When removing plastic Pin tip covers, pull the cover straight off the Pin to avoid Pin tip damage.

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com (under the subject heading please type "ArrayIt® technical assistance"). By email: arrayit@arrayit.com, Monday–Friday PST 9:00am - 4:30pm. Please remember that we want to hear about your successes!

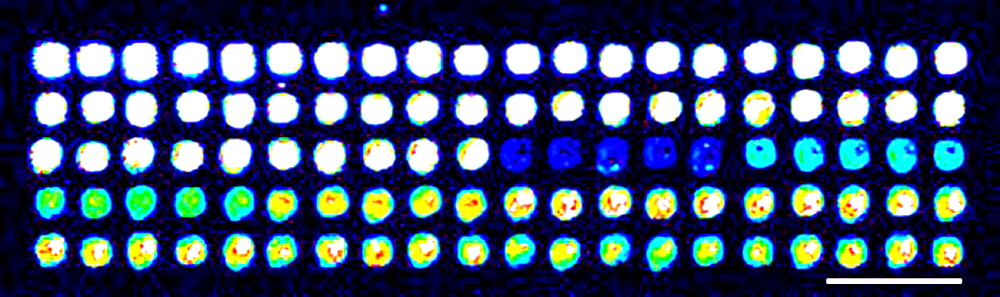

Figure 8. Microarray printed with 10-fold serial dilutions of ArrayIt® Green540 and Red640 fluorescent dyes at a 1:1 ratio. A total of 20 samples were printed in quintuplicate at 200 µm spacing on SuperAmine Substrates using a SpotBot® 2 equipped with four 946MP4 Pins. Elements 51-55 (row 3, spots 11-15) contain dye at 0.01 fluors/µm2, which corresponds to approximately 120 dyes or 12 labeled proteins per microarray spot. Spot morphology is somewhat non-uniform because samples were diluted in dH2O to prevent scanning artifacts. Scanning was performed using a ScanArray Express (PerkinElmer) set at 70% PMT and 90% laser power in the green (“Cy3”) and red (“Cy5”) channels. The Green540 data are coded to a rainbow palette for ease of viewing. The space bar denotes 500 µm.

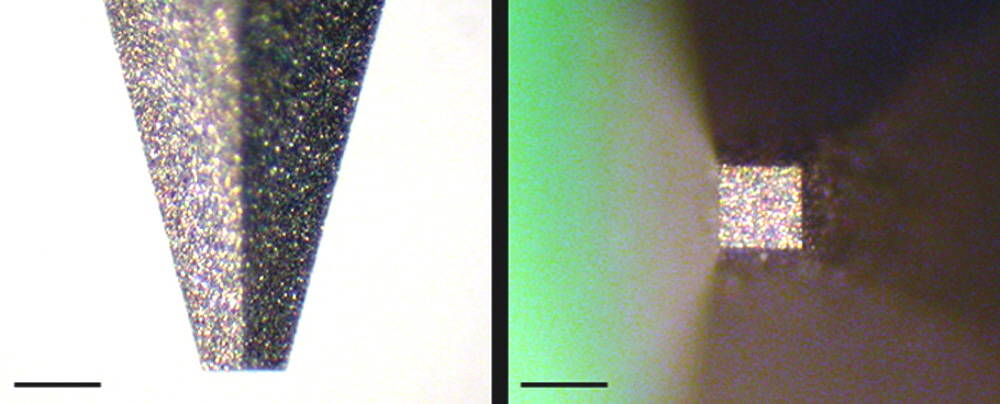

Figure 9. 946NS6 Pin Photos. Shown is a 946 "No Sample Channel" (946NS) Pin with a 0.006" (150 µm) wide tip used for applications requiring solid pins of exacting dimensions. The solid point of the 946NS6 Pin is shown as a side view (left) and the tip is shown from the bottom up (right). The space bars denote 150 µm.

Figure 10. Shown are 946 microarray printing technology components, including four 946MP4 Pins, a 946PH48 Printhead, and a 946PT Pin Tool. Stealth and 946 Pins and Printheads are fully interchangeable except that Stealth Pins have standard collars.

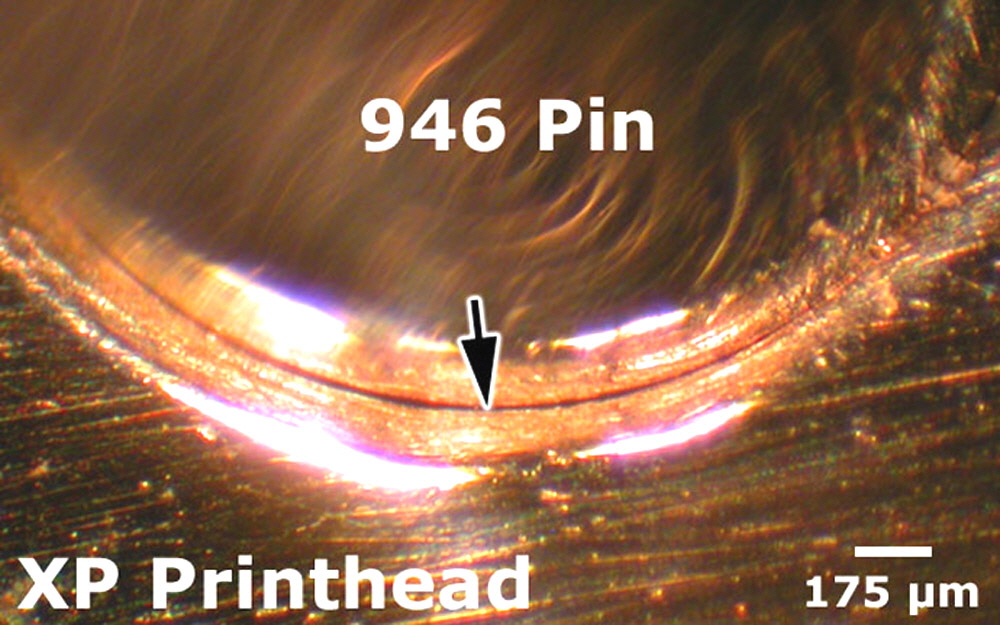

Figure 11. Shown is a high-magnification (90X) photograph of a 946MP2.5 microarray printing pin (946 Pin) inserted into our innovative 946PH48XP Extra Precision Printhead. The XP Printhead offers Extra Precision (XP) guiding holes for tighter Pin-Printhead tolerances (arrow) and 5 µm greater positional accuracy compared to standard 946 Printheads. The result is straighter rows and columns of printed spots and greater data precision. ArrayIt® 946XP Printheads are slightly more sensitive to Pin and Printhead contaminants and are recommended for experienced “enthusiast” users and class 1 or better cleanroom facilities. Microarray Cleanroom Gloves must be worn at all times when working with 946XP Printhead technology.

Figure 12. High-density 946MP1.5 microarrray printing pin with 37.5 µm tip, 0.25 µl sample channel and extended collar, enabling 60 µm center-to-center spot spacing and 270,000 and 360,000 printed spots, respectively, in a 48-pin 18 x 54 mm and 64-pin 18 x 72 mm glass substrate slide area.

Storage Conditions

Arrayit's 946 style Pins, Printheads and accessories are manufactured using the most advanced micromachining, surface chemistry, materials, and procedures available. These products are stable indefinitely when stored at room temperature (20-25°C) and ambient humidity (25-50%) and will provide years of reliable use if maintained properly. Avoid exposure to strong solvents, and extremes in temperature, humidity, and pH. Keeping these implements dry and dust-free will improve performance. Please read instructions carefully prior to use. Regular maintenance using the Pin and Printhead Cleaning Kit will is highly recommended. When removing the protective plastic Pin tip covers, pull the cover straight off the Pin rather than using a twisting motion, which can bend the Pin tips.