SuperClean

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarray Substrates & Slides - SuperClean and SuperClean 2 Glass Substrate Slides for Microarray Surface Chemistry, Silanization and Manufacturing

ArrayIt® SuperClean 2 Microarray Substrates are a new and improved version of our original SuperClean product line provides the basis for all our microarray surface chemistry products. This is the only microarray substrate line in the world that is polished to atomic smoothness of <±20 angstroms, providing the most homogenous surface available in the industry. Cleaned at the atomic level in state-of-the-art class 1 cleanrooms and heat-sealed in anti-static packaging, these superior glass substrates are cut to standard glass slide dimensions (25 x 76 mm) and are compatible with all major brands of microarrayers and scanners. SuperClean 2 Substrates have a proprietary corner chamfer for unambiguous side orientation. They are untreated and ready for custom surface chemistry. Our SuperClean 2 products outperform optical quality glass from other vendors and are the substrates of choice for high-density DNA and protein microarray manufacturing applications by contact printing and in situ synthesis methods.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Technical Notes

- Technical Assistance

- Short Protocol

- Complete Protocol

- Troubleshooting Tips

- Recommended Equipment

- Ordering Information

- Storage Conditions

- Warranty

Introduction

The use of ArrayIt® brand products will improve the precision, speed and affordability of your microarray research in genomics, proteomics, biomedicine, pharmaceuticals, diagnostics and agriculture. This handbook contains all the information required to take full advantage of Arrayit's ArrayIt® brand SuperClean 2 Microarray Substrates.

Quality Control

Arrayit uses the highest quality control (QC) and quality assurance (QA) measures to ensure the quality of our ArrayIt® brand SuperClean 2 Microarray Substrates. The finest science and engineering was used to develop this product line. The use of ultra-pure reagents, atomic-level cleaning, class 1 cleanroom manufacturing and rigorous 6-step optical analysis of every substrate guarantees that this product line outperforms the highest industry standards.

Product Description

ArrayIt® brand SuperClean 2 Microarray Substrates represent the highest quality glass substrate in the microarray industry. All of our substrates are polished to atomic smoothness and manufactured in a state-of-the-art class 1 cleanrooms, with strict controls on particulate, biological and static contaminants, as well as temperature and humidity control. These pristine silicon dioxide substrates offer quality and performance that cannot be obtained by any other vendor.

Users will appreciate the following:

- Polished to atomic surface smoothness <±20 angstroms over 1.0 µm2

- Superior substrate flatness of <0.036 mm over 25 x 76 mm

- Only polished glass substrate/slide in the microarray industry

- Homogenous SiO2 groups provide superior silane reactivity

- Vastly superior to unpolished optical quality glass from other vendors

- Ultimate surface for ultra-high density DNA and protein microarray manufacturing including micro-mirror, photolithography and contact printing

- Used by high-volume microarray manufacturing companies

- Topological smoothness ensures uniform hybridization layer

- Manufactured in a state-of-the-art class 1 cleanrooms

- Ultra-low intrinsic fluorescence

- Superior surface for chemical treatments (e.g. silane reagents)

- Ideal for gel and membrane coatings (e.g. polyacrylamide and nitrocellulose)

- Widely-used for in situ and ex situ synthesis

- Used in-house for ArrayIt® brand content microarrays including H25K

- Open platform dimensions compatible with all major brands of microarrayers and scanners

- Precise physical dimensions (25 ± 0.2 mm x 76 ± 0.3 mm x 0.940 mm ± 0.025 mm)

- Proprietary corner chamfer (1.4 mm) provides unambiguous side and end orientation

- Finished edges enhance user safety

- Excellent refractive index, transmission and hardness specifications

- Sophisticated anti-static packaging improves usability

- Offered with or without bar-codes

- Custom sizes and thicknesses available upon request

- Custom laser and chrome fiducials available upon request

- Product arrives “ready for chemistry” with no additional cleaning required

- High-volume 100,000 piece per month manufacturing capabilities

Figure 1. Schematic illustration of an ArrayIt® brand SuperClean 2 Microarray Substrate, containing reactive silicon dioxide groups on the polished, atomically flat glass substrate. This product is ideal for researchers and microarray manufacturing organizations that wish to add their own chemical treatments and coatings. The corner chamfer allows unambiguous side and end orientation, and our convention is to print on the side shown in this diagram rather than on the backside. See Fig. 5 for additional information on the correct chamfer location relative to the printed microarray elements.

Technical Notes

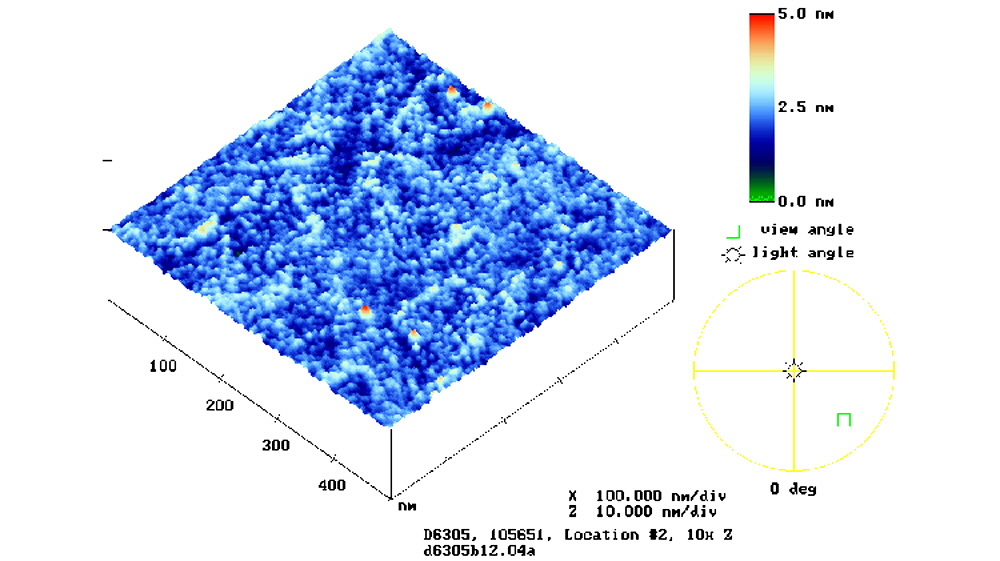

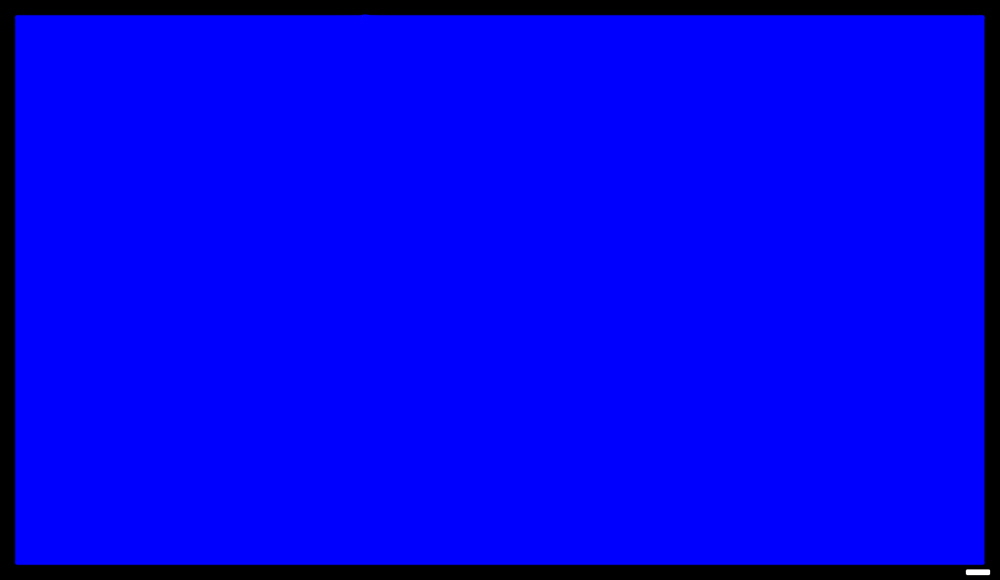

ArrayIt® brand SuperClean 2 Microarray Substrates are polished at high precision to achieve atomic-level smoothness of ±20 angstroms (Fig. 2). The advantages of glass polishing are several-fold. Polishing provides a uniform density of silicon dioxide groups for uniform chemical reactivity with reagents such as organosilanes. Organosilanes, in turn, determine the coupling uniformity and efficiency of DNA and protein target molecules. SuperClean 2 products enable better uniformity and higher coupling efficiency of molecules such as oligonucleotides, cDNA, proteins, antibodies, and other molecules of interest. Improved feature quality translates into greater data precision, which makes our SuperClean 2 surface ideal for high-density DNA and protein microarray applications. A second advantage of glass polishing is that topological smoothness reduces “peaks and valleys” in the glass, which enables uniform hybridization layer thickness and improved precision. Unpolished surfaces inherently produce uneven hybridization layers causing signal intensities to vary due to different quantities of probe molecules available for hybridization. The same concepts hold for biochemical reactions of proteins and other molecules. A third advantage of glass polishing is seen in the scanning step. Atomically flat surfaces provide a precisely calibrated distance from the glass to the scanner optics, producing highly uniform scanning data (Fig. 3). Standard optical quality glass slides and microscope slides from other vendors do not provide the advantages conferred by ArrayIt® brand polished glass substrates. We use the term “substrate” instead of “slide” to distinguish our products from the lesser quality microscope slides offered by other vendors.

Figure 2. Atomic force microscopy (AFM) scanned image of a SuperClean Microarray Substrate, with smoothness data represented in a color palette. The scale bar (upper right) denotes surface smoothness in nanometers (nm). 1 nm = 10 Å. SuperClean (shown) and SuperClean 2 are flat to ±25 and ±20 Å, respectively.

Figure 3. Uniformity scan of anArrayIt brand SuperClean 2 Microarray Substrate acquired at high scanner sensitivity. The SuperClean 2 Substrate was scanned at 10 µm-resolution using a GenePix 4000A microarray scanner (Molecular Devices) set at 100% laser power and photomultiplier tube (PMT) gain 900 in the 532 nm (cyanine 3) channel. Signal intensities vary by less than 1% over the 22 x 40 mm area. The data are represented in a color palette and the space bar corresponds to 1.0 mm.

Table 1. Shown is a quality comparison between ArrayIt® SuperClean and SuperClean 2 Microarray Substrates. The SuperClean 2 products represent new and improved versions of our original SuperClean product line.

Specification |

SuperClean |

SuperClean 2 |

Atomic smoothness |

±25 Å |

±20 Å |

Glass cleaning procedure |

Dual temperature, triple phase atomic |

Triple temperature, quadruple phase atomic |

Moisture content |

Low |

Undetectable |

Optical QC procedure |

5-tier inspection and laser scanning |

6-tier inspection and laser scanning |

Minimum microarray feature size |

5 µm |

1 µm |

Maximum microarray feature number (22 x 72 mm area) |

15,840,000 |

396,000,000 |

Technical Assistance

Please contact us if you have any questions, comments, suggestions, or if you need technical assistance. By electronic mail, use arrayit@arrayit.com and type "ArrayIt technical assistance" into the subject line. By telephone, call (408) 744-1331 between the hours of 8AM and 7PM PST Monday through Friday. We want to hear about your successes and are always happy to publish contributed sample data on our website.

Short Protocol (Steps 1-5)

1. Decontaminate shipping envelope to remove particles.

2. Transfer glass substrates to processing hardware.

3. Add custom surface chemistry or surface coating.

4. Process activated substrates to prepare for manufacturing.

5. Manufacture microarrays containing DNA, protein and other types of molecules.

Complete Protocol (Steps 1-5)

1. Decontaminate shipping envelope to remove particles. Using ArrayIt® brand Microarray Cleanroom Wipes and the Microarray Air Jet, wipe down the silver anti-static package with 95% ethanol and blow dry to remove dust and other contaminants that may have accumulated during shipping. This cleaning process prevents contamination of the substrates once the anti-static package and substrates box are opened.

2. Transfer glass substrates to processing hardware. With a scissors, cut the silver anti-static envelope 1 cm from the top between the zip-lock and the heat seal seam. This allows the envelop to be opened and re-sealed using the zip-lock. Remove the white box containing the substrates and carefully remove the lid by lifting it upward gently. Remove the cleanroom cloth located over the SuperClean 2 Substrates. Carefully transfer the substrates to slide racks, spin coating systems or custom holders used to the surface chemistry or surface coating. The corner chamfer can be used to orient the SuperClean and SuperClean 2 Substrates during this process. Make sure the chamfer is located at the same position for each substrate.

3. Add custom surface chemistry or surface coating. A wide range of silane reagents, gels, membranes and other types of treatments and coatings can be used to modify the glass surface so that it attaches target molecules of interest. The basic criteria for a surface chemistry are stable attachment to the glass surface, strong coupling efficiency and low background. SuperClean and SuperClean 2 Substrates provide the ultimate starting points for surface chemistry owing to the extraordinary quality of these glass surfaces.

4. Process activated substrates to prepare for manufacturing. After the surface chemistry is added, the activated glass substrates should be processed to remove excess chemicals, solvents, particulates, and other contaminants in the surface treatment or surface coating that may interfere with downstream biochemical steps. Processing can be as simple as rinsing the activated substrates in distilled H2O or a compatible solvent. After the processing steps, substrates should be spun dry to remove excess liquid and dried thoroughly before use. Bar codes can also be added at this step to aid in identification and tracking. According to our convention, the bar code should be placed horizontally across the lower end of the substrate such that the chamfer appears in the upper right shown in Fig. 1.

5. Manufacture microarrays containing DNA, protein and other types of molecules. The activated and processed substrates are suitable for microarray manufacturing using both in situ (monomer-by-monomer) and deposition (delivering pre-synthesized molecules) strategies on the SuperClean and SuperClean 2 surfaces. Photolithography, micro-mirrors, contact pin printing and ink-jetting are among the common enabling technologies used to deliver DNA bases, oligonucleotides, cDNAs, antibodies, recombinant proteins, peptides, carbohydrates, cell extracts, tissue sections and other types of samples. For the in situ methods, manufacturing and attachment occur simultaneously. For deposition, the molecules should be attached to the surface after delivery using dehydration, drying, heat treatment, cross-linking, or other suitable means. Custom fiducials can be added to the glass surface to aid in manufacturing and use (Fig. 4). After the attachment step, the manufactured microarrays should be processed to remove unbound target molecules and stored in cool, dry conditions prior to use. Vacuum packaging can be used to improve microarray shelf life. ArrayIt® uses the SuperClean 2 surface as the starting point for all of its content chips (Fig. 5).

Figure 4. Shown is a photograph of a laser-etched fiducial mark on a SuperClean 2 Microarray Substrate. ArrayIt® has laser-etching capabilities suitable for making custom fiducials of any shape and dimension (please inquire). The space bar corresponds to 100 µm (0.0039”).

Figure 5. Shown is a photograph of ArrayIt® H25K Human Genome and CheckIt Chips microarrays printed on activated SuperClean 2 Microarray Substrates. Spots are visible due to reflection off the salt crystals formed in the printed elements. The SuperClean and SuperClean 2 surfaces provide the ultimate starting point for content microarrays, enabling high coupling efficiency, excellent spot morphology, high signals and low background.

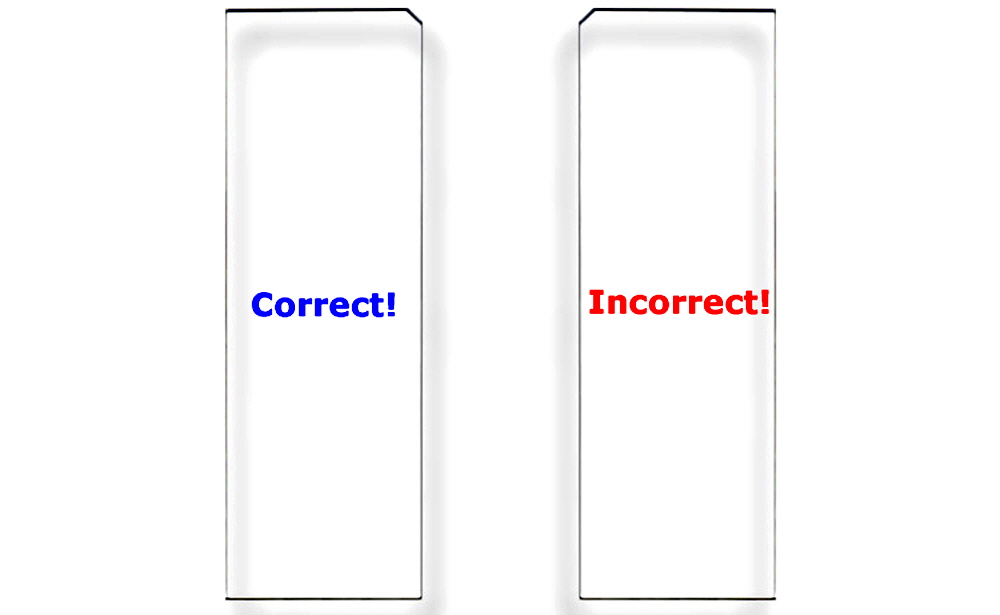

Figure 6. Correct Substrate Orientation. Shown is a graphic of two ArrayIt® Microarray Substrates, showing the correct and incorrect orientation for use. In the correct orientation (blue graphic), the chamfer will be located in the upper right corner and samples should be printed on the side facing upward, which is the same side that contains the word “Correct!”. In the incorrect orientation (red graphic), the chamfer will be located in the upper left corner, placing the backside facing upward, which is the side that contains the word “Incorrect!”. Only one side of ArrayIt® Microarray Substrates is suitable for printing. Please print on the correct side only.

Troubleshooting Tips

1. Weak hybridization or binding signals

- Ineffective surface chemistry treatment (check silane reagents)

- Ineffective membrane, gel or surface coating (check binding properties)

- Inefficient probe labeling (check labeling reaction and fluorescent reagents)

2. High background fluorescence or noise

- Surface chemistry treatment causes non-specific binding

- Membrane, gel or surface coating traps labeled molecules

- Probe mixture contaminated with unincorporated fluors

Scientific Publications

Click here and here for recent scientific publications using ArrayIt® brand SuperClean Microarray Substrates from Arrayit International, Inc.

Recommended Equipment and Reagents

NanoPrint™ 2 Microarrayers

SpotBot® 4 Personal Microarrayers

InnoScan® Microarray Scanners

SpotLight™ 2 Microarray Scanners

Microarray Hybridization Cassettes

High Throughput Wash Station

Microarray High-Speed Centrifuge

Protein Printing Buffer

BlockIt™ Blocking Buffer

Microarray Air Jet

Microarray Cleanroom Wipes

PCR Purification Kits

BlockIt Blocking Buffer

Micro-Total RNA Extraction Kit

MiniAmp mRNA Amplification Kit

Indirect Amino Allyl Fluorescent Labeling Kit

Universal Reference mRNA

Green540 and Red640 Reactive Fluorescent Dyes

Hybridization Buffers