SuperAvidin Slides

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

ArrayIt® SuperAvidin Microarray Substrates contain a highly uniform avidin treatment covalently bound to an atomically flat glass substrate, affording a universal high-capacity biotin-binding surface for DNA and protein microarray applications and many other life sciences applications that require a biotin binding surface. The open platform 25 x 76 mm glass substrate slide format renders SuperAvidin Microarray Substrates compatible with all standard microarrayers and scanners.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Technical Specifications

- Technical Assistance

- Recommended Equipment

- Ordering Information

- Storage Conditions

- Warranty

Introduction

Congratulations on taking a big step towards improving the affordability, quality and speed of your genomics, biomedical, pharmaceutical and agricultural research. This booklet contains all the information required to take full advantage of ArrayIt® SuperAvidin Microarray Substrates.

Quality Control

Arrayit takes every measure to assure the quality of our ArrayIt® Brand Super Microarray Substrates. The finest microarray biochip cleanroom research was used to develop these products. Rigorous quality control monitoring on a substrate-by-substrate basis guarantees that each these products conforms to the highest industry standards.

Product Description

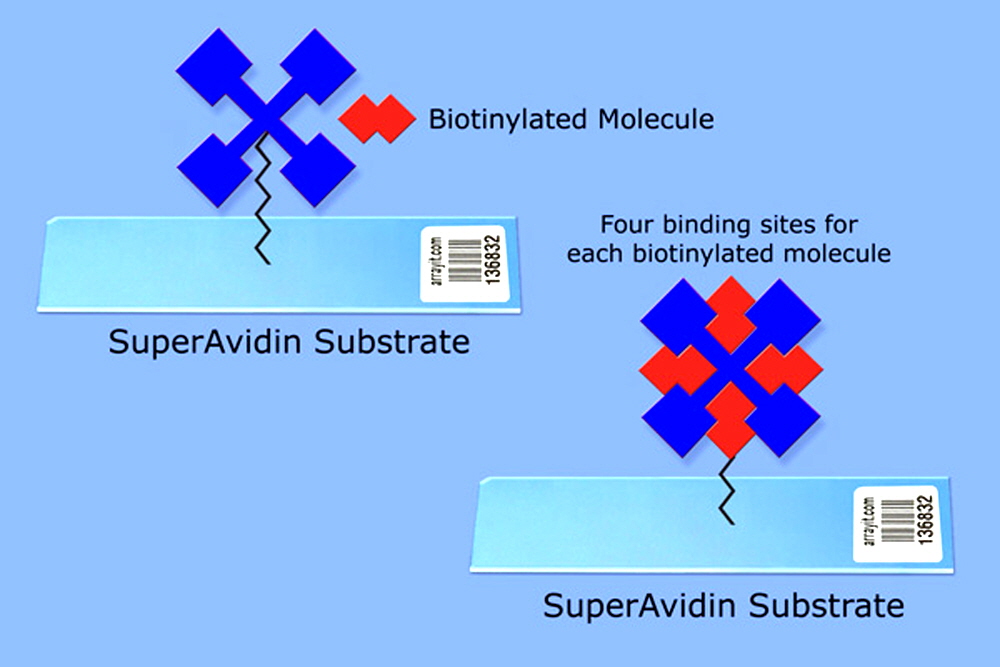

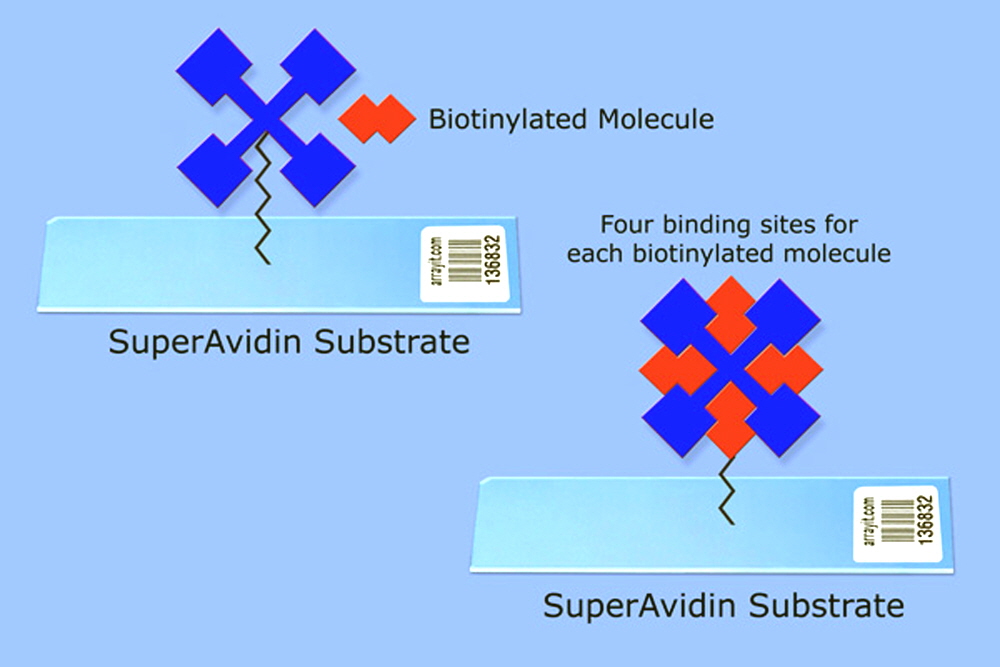

The SuperAvidin Substrate has covalently attached avidin over the entire surface of the substrate for binding biotin labeled molecules. These substrates have high binding capacity, low background fluorescence for high signal to noise ratio and can be used for genomic and proteomic microarrays. The slides are standard 25x76 mm format and fit in all standard microarray scanners and are packaged in white plastic boxes and vacuum packed. This surface starts with ArrayIt SuperClean glass then it is activated with high quality avidin to bind biotinylated biomolecules. The avidin is covalently bound to the surface and will not flake or peel off. It’s binding to biotin is so strong it is effectively irreversible. Avidin is composed of four identical subunits, each of which has a binding site for biotin. SuperClean is a highly polished glass surface with an optical smoothness tolerance of 50 angstroms over the entire 25mm x 76 mm surface area for optimum homogeneity, this new surface sets the highest quality standard for avidin substrates for microarray applications.

Figure 1. SuperAvidin Substrates are saturated with covalently bound avidin. Each avidin molecule on the surface is capable of binding up to four biotinylated molecules. Biotinylated proteins, DNA and other molecules can be bound to this surface to perform a variety of microarray based binding and hybridization studies.

Short Protocol Protein (Steps 1-7):

1. Suspend biotinylated protein samples in Protein Printing Buffer at 0.25-1 µg/µl.

2. Print protein samples onto SuperAvidin Substrates.

3. Block with Superavidin blocking buffer and then wash and dry the printed microarrays.

4. React the processed microarrays with fluorescent samples.

5. Wash the microarrays to remove un-reacted fluorescent material.

6. Scan the microarray to produce a fluorescent image.

7. Quantitate and model the fluorescent data.

Short Protocol DNA (Steps 1-7):

1. Suspend biotinylated DNA samples in Micro Spotting Solution Plus.

2. Print DNA samples onto SuperAvidin Substrates.

3. Block with Superavidin blocking buffer and then wash and dry the printed microarrays.

4. Hybridize the processed microarrays with fluorescent probe.

5. Wash the microarrays to remove unreacted fluorescent probe.

6. Scan the microarray to produce a fluorescent image.

7. Quantitate and model the fluorescent data.

Technical Specifications:

SuperAvidin Microarray Substrate Slides are manufactured in class 1 cleanrooms using atomically smooth polished glass substrate slides followed by activation with a covalent monolayer of a ultra-high purity avidin protein molecules. Users will benefit from the following technical features:

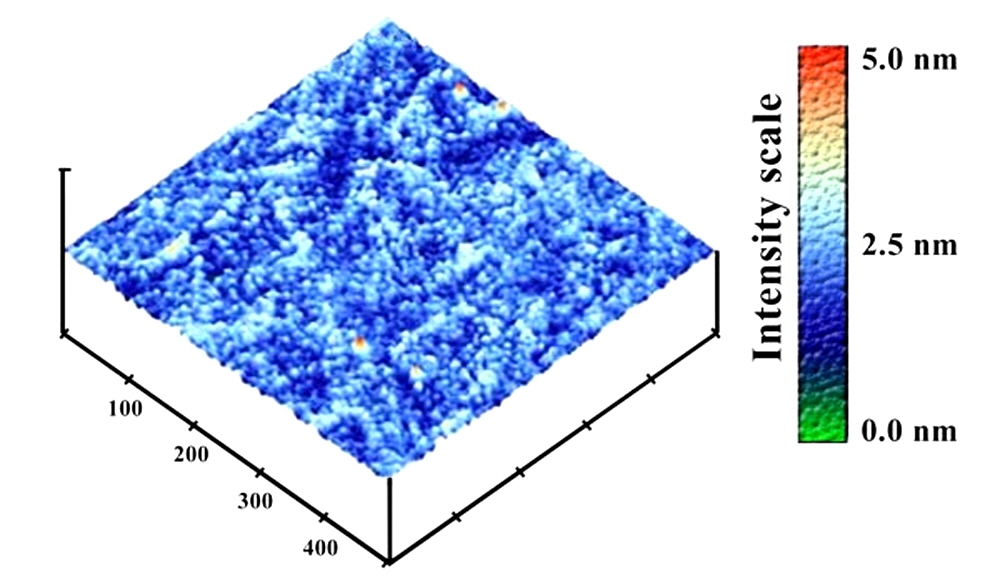

- Glass polished to atomic smoothness (±20 angstroms)

- Only polished glass surface in the microarray industry

- Polishing improves topology and uniformity – keys to precise data

- Homogenous avidin protein monolayer provides superior biotin binding

- Avidin molecules bound covalently to the glass substrate

- Avidin monolayer contains 1.1 x 10^10 avidin proteins/mm2

- Avidin monolayer covers the entire 25 x 76 mm surface area

- Vastly superior to unpolished optical quality glass from other vendors

- Ultimate avidin surface for high density microarray applications

- Ideal for contact and non-contact printing

- Used by high-volume microarray core facilities

- Manufactured in a state-of-the-art class 1 cleanrooms

- Ultra-low intrinsic fluorescence and background noise

- Open platform dimensions compatible with all major brands of microarrayers and scanners

- Precise physical dimensions (25 ± 0.2 mm x 76 ± 0.3 mm x 0.940 mm ± 0.025 mm)

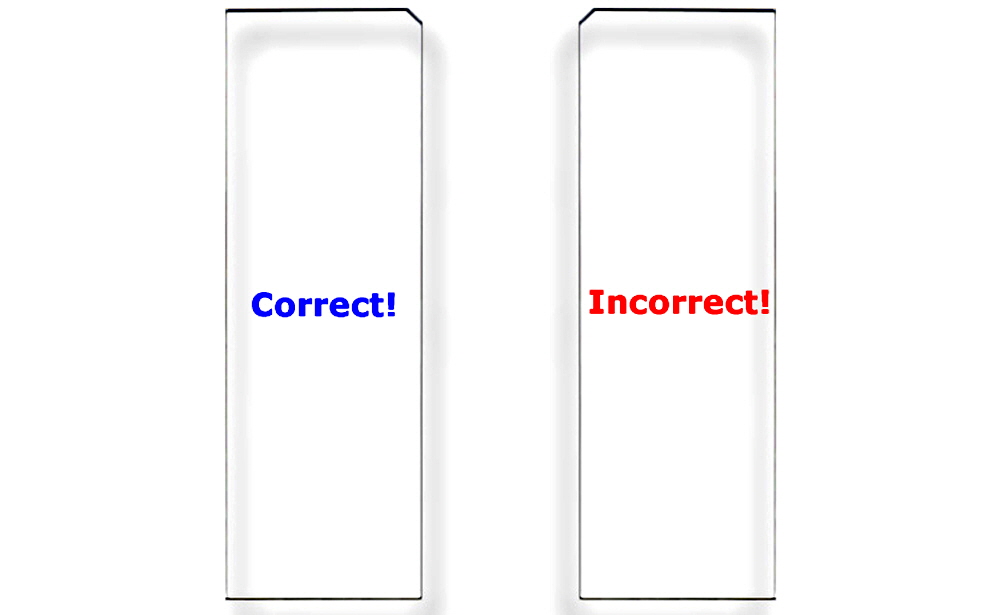

- Proprietary corner chamfer (1.4 mm) provides unambiguous side and end orientation to simplify printing and processing

- Finished edges enhance user safety

- Excellent refractive index, transmission and hardness specifications

- Sophisticated anti-static packaging improves usability

- Offered with or without bar-codes

- Custom laser and chrome fiducials available upon request

- High-volume 100,000 piece per month manufacturing capabilities

- Product arrives “ready to use” with no additional processing required

Figure 2. Atomic Force Microscopy (AFM) analysis. Shown are AFM scans of the SuperClean Microarray Substrate by Arrayit ArrayIt Division, Sunnyvale CA. Data are coded to a rainbow intensity scale, such that red data represents 5.0 nm or 50 angstroms. The substrates have an average smoothness of 2.0 nm or 20 angstroms, which corresponds to about 10 silicon dioxide bonds.

Figure 3. Correct Substrate Orientation. Shown is a graphic of two ArrayIt® Microarray Substrates, showing the correct and incorrect orientation for use. In the correct orientation (blue graphic), the chamfer will be located in the upper right corner and samples should be printed on the side facing upward, which is the same side that contains the word “Correct!”. In the incorrect orientation (red graphic), the chamfer will be located in the upper left corner, placing the backside facing upward, which is the side that contains the word “Incorrect!”. Only one side of ArrayIt® Microarray Substrates is suitable for printing. Please print on the correct side only.

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com under the subject heading please type "ArrayIt® technical assistance"). By email: arrayit@arrayit.com, Monday–Friday PST 9:00am - 4:30pm. Please remember that we want to hear about your successes!

Scientific Publications

Click here and here for recent scientific publications using ArrayIt® brand SuperAvidin and other products from Arrayit International, Inc for avidin experimentation.

Recommended Equipment and Reagents

NanoPrint™ 2 Microarrayers

SpotBot® 4 Personal Microarrayers

InnoScan® Microarray Scanners

SpotLight™ 2 Microarray Scanners

Microarray Hybridization Cassettes

High Throughput Wash Station

Microarray High-Speed Centrifuge

Protein Printing Buffer

BlockIt™ Blocking Buffer

Microarray Air Jet

Microarray Cleanroom Wipes

PCR Purification Kits

BlockIt Blocking Buffer

Micro-Total RNA Extraction Kit

MiniAmp mRNA Amplification Kit

Indirect Amino Allyl Fluorescent Labeling Kit

Universal Reference mRNA

Green540 and Red640 Reactive Fluorescent Dyes

Hybridization Buffers