Vacuum Pump

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Microarray vacuum pumps AVP oil-free quiet operation low vibration cleanroom 110 220 volt life sciences research

Instruments - Microarray Processing - Oil-Free Cleanroom Vacuum Pumps

Arrayit vacuum pumps set a new standard for oil-free cleanroom laboratory vacuum pumps. Our AVP products are extremely quiet, rugged and durable, and can be used for the full spectrum of microarray, life sciencs and semi-conductor applications including solution filtration, vacuum stations, vacuum manifolds for DNA purification, cleanroom accessories, and many applications.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Technical Specifications

- Technical Assistance

- Short Protocol

- Complete Protocol

- Equipment

- Troubleshooting Tips

- Ordering Information

- Operation Conditions

- Warranty

Introduction

Congratulations on taking a big step towards improving the economies of scale, quality and speed of your genomics research. This booklet contains information needed to use Arrayit’s ArrayIt® Brand Vacuum Pump (AVP).

Quality Control

Arrayit assures the performance of this product. The finest scientific research went into the development of this product. Rigorous quality control monitoring of every instrument guarantees that this vacuum pump exceeds the highest industry standards.

Product Description

Arrayit’s ArrayIt® Brand Vacuum Pumps (Cat. AVP and AVP220) set a new standard for laboratory vacuum pumps. The AVPs are extremely quiet, rugged and durable, and can be used to power vacuum stations in microarray robots, vacuum manifolds for DNA purification, vacuum filtration, and many other laboratory applications.

Users will appreciate the following features:

- Compatible with all microarray robot dry stations

- Ideal for PCR Purification and other microplate-based kits

- Can be used with any vacuum manifold

- Near noise-free operation of 45dB

- Ultra-low vibration

- Low thermal output

- Excellent all-purpose vacuum pump for laboratory applications

- Oil-free and fully cleanroom compatible

- Rugged design ensures years of maintenance-free performance

- In-line filter traps particles and vapors

- Quick release tubing connector simplifies use

- Uses convenient 5/16” and 3/8” (8 and 10 mm) vacuum tubing

- Vacuum meter on front of unit allows easy reading

- Easy access on/off switch

- 110-volt and 220-volt versions for world-wide usage

Technical Specifications

- 0.8 bar vacuum pressure (Maximum Vacuum 440mbar-550mbar)

- 2.1 cubic feet per minute (70 liters/min) air flow

- 45 decibel (dB) noise level at 1 meter

- Input hose fitting ports of 10mm + 6mm or 3/8" + 1/4

- 2 meter (6 ft) power cord

- Weight: 18 lbs (8.1 kg)

- Size (L, W, H): 12.4 x 7.1 x 8.7 in (315 x 180 x 220 mm)

- CE approved

- Low power consumption of 95 watts

- U.S. version (Cat. AVP): 110 volts at 60 Hz

- Overseas version (Cat. AVP220): 220 volts at 50 Hz

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com (under the subject heading please type ArrayIt technical assistance). By email: arrayit@arrayit.com, Monday—Friday PST 9:00am - 4:30pm. Please remember that we want to hear about your successes!

Short Protocol

- Remove Vacuum Pump from packaging material.

- Insert plug into a standard 3-prong 110-volt outlet.

- Insert vacuum tubing into red “quick connect” port.

- Turn on red power switch.

- Turn off red power switch after use.

Complete Protocol

- Remove Vacuum Pump from packaging material. For standard laboratory use, simply remove packaging material and use immediately. For cleanroom use, decontaminate the packaging material with forced air and ethanol prior to moving the unit into the cleanroom vestibule. Once inside the vestibule or changing area, unwrap the pump and transport into the cleanroom. The oil-free operation is ideal for cleanroom applications.

- Insert plug into a standard 3-prong 110-volt outlet. Unwrap the black power cord and insert it into a standard 110-volt electrical outlet containing 3 ports.

- Insert vacuum tubing into red “quick connect” port. Connect the vacuum manifold, microarray robot dry station, filtration apparatus, or any other device of interest by inserting a length of 1/4” (6.4 mm) rigid vacuum tubing into the quick connect port on the front of the instrument. Press the tubing into place firmly, making sure that the tubing penetrates the beveled portion on the interior of the quick connect. Rigid vacuum tubing such as irrigation tubing is ideal because it inserts more readily, though softer tubing types such as silicon tubing also work well. To disconnect the tubing, press inward on the red collar of the connector, and pull firmly outward on the tubing. Do not attempt to disconnect the tubing without first pressing inward on the red collar.

- Turn on red power switch. Vacuum pressure is initiated by powering on the Vacuum Pump using the red power switch on the front of the unit. The vacuum limiter pressure knob stops the strength of the vacuum exceeding whatever you have set it to.

- Turn off red power switch after use. The ArrayIt Vacuum Pump (AVP) is not intended for continuous use. Please power the unit down after each use. Nominally, the pump is intended to be used for up to 8 consecutive hours, after which time the unit should be powered down. Continuous use may result in accelerated wear and may pose a safety hazard due to overheating.

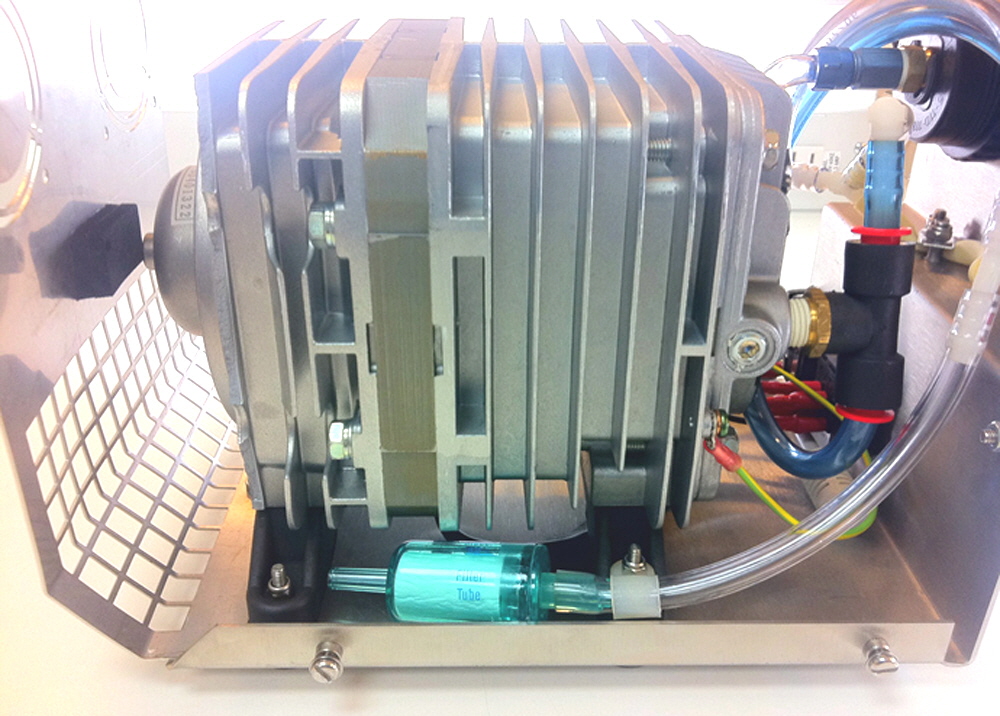

Fig. 1. ArrayIt® brand Vacuum Pumps (AVP) running a microarrayer dry station in dual mode in a class 100 cleanroom. Two pumps are connected in parallel for greater performance. The quiet, low thermal output, oil-free operation is ideal for a cleanroom environment.

Fig. 1. ArrayIt® brand Vacuum Pumps feature 0.1 µm air filtration on the air intake and a fully sealed pump to prevent particulate generation during use. Vacuum pumps are decontaminated completely after manufacturing and testiing to remove particulates and biological contaminants. Arrayit pumps are extremely quiet during operation, offer low thermal output and oil-free operation, and are ideal for use in class 1-1,000 cleanroom environments for research, life sciences, diagnostics, healthcare and other applications.

Linear Pump Operating Principle

The activated electromagnet attracts the piston against the return spring, while air is taken into the cylinder through the open inlet valve. When the electromagnet is deactivated, the return spring pushes the piston back, and the compressed air is moved out of the cylinder through the outlet valve.

Equipment and Reagents

Vacuum Filter Manifold

PCR Purification Kits

Fluorescent Probe Purification Kits

Dye Terminator Cleanup Kits

Cleanroom Wipes

Troubleshooting Tips

Pump fails to pull sufficient vacuum

- Adjust the black pressure screw beneath the pressure gauge.

- Make certain the 5/8” tubing is inserted fully in the quick release

Scientific Publications

Click here and here for recent scientific publications using ArrayIt® brand products and vacuum-based approaches.