SpotBot® 4

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarrayers - SpotBot® 4 Desktop Personal, SpotBot® 4 Protein Edition and SpotBot® 4 HotBot Edition Microarrayers

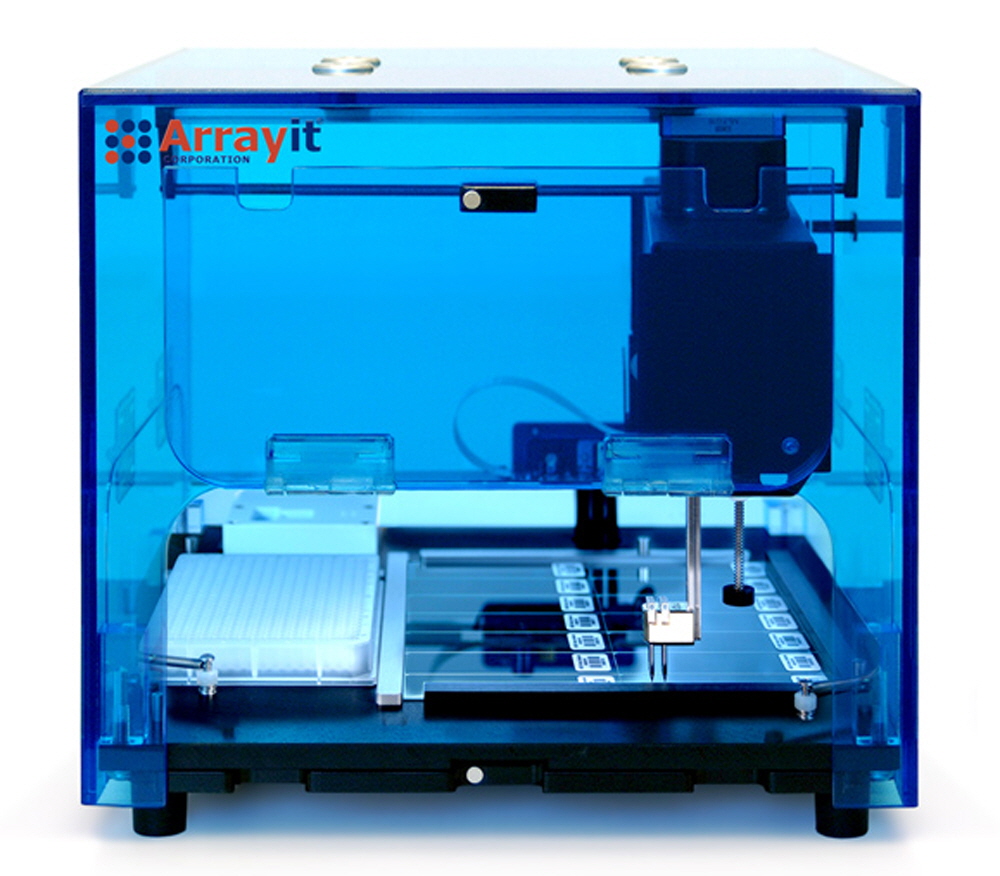

New!! Arrayit SpotBot® 4 Personal Microarrayers provide the market's most advanced personal microarrayers, featuring our patented contact printing technology installed in more than 4,200 laboratories worldwide. SpotBot® 4 Microarrayers empower DNA, oligonucleotide, amplicon, BAC, antibody, antigen, peptide, carbohydrate, small molecule, lipid, cell extract and whole cell microarray manufacturing in minutes on your desktop for genotyping, gene expression, protein expression profiling, protein binding, and myriad other microarray applications. Large OEM arrangements permit the integration of your microarray manufacturing application into our time-tested personal microarray platform. SpotBot® 4 systems include a BioBlue personal computer, LED display, keyboard, mouse, mouse pad, cables and accessories for easy installation.

SpotBot® 4 System Specifications and Features

- SpotBot® 4 instruments represent a significant advance over earlier SpotBot® 1-3

- Extra heavy duty gantry offers improved precision, speed and durability

- Arrayit patented contact printing technology (U.S. 6,101,946) adds confidence

- Vision System option allows high-resolution printing on custom substrates and devices

- Professional series printhead permits precision pin guidance for precise rows and columns

- Four printing pins configured in a 2 x 2 pattern at 4.5 mm spacing

- Professional series printhead reduces friction and allows minimal force contact printing

- Axis resolution and repeatability of ±10 µm

- Deck accommodates 14 standard glass substrate slides (1 x 25 x 76 mm)

- Deck accommodates 1 microplate (384-wells)

- Complete deck and microplate cooling from ambient to 4°C for Protein Edition

- Complete deck and microplate heating from ambient to 45°C for “HotBot”€ Edition

- Humidity control option from 10-80% relative humidity (RH)

- Megasonic Wash Station option enhances pin cleaning

- Compatible with all professional, 946 and Stealth microarray printing pins

- Printing routines allow 1-5 technical replicates per sample

- 3,600 spots per sub-microarray (9 x 9 mm)

- 50,400 spots per entire substrate (18 x 63 mm)

- Printing time of 2 hrs per 384-well microplate

- >1,000 samples in 6 hours

- Runs on Microsoft Windows 7

- Power requirements: Standard 120-volt or 220 volt outlets

- Ease-of-operation via new version 4 Graphical User Interface (GUI)

- SpotBot® 4 size (H x L x W): 29 cm (11.5 in) x 30 cm (11.8 in) x 30 cm (11.8 in)

- SpotBot® 4 weight: 6.2 Kg (13.6 lbs)

- Private branding, OEM agreements and large volume pricing available

- World’s only truly portable desktop microarrayers

- World’s only turnkey desktop protein microarray manufacturing systems

- Create a miniature “cold room”€ on your desktop with 4°C Protein Edition deck cooling option

- Flow-through liquid cooled platen maximizes deck cooling speed, efficiency and uniformity

- Systems shipped with factory calibration for ease of set-up and use

- Micro-robotics enable precision motion control in a highly compact footprint

- Near zero thermal emission, ultra-low energy consumption, and quiet operation

- Rapid flow wash station and forced air pin drying enables efficient pin cleaning

- Humidity control of 5% per minute and ±1 % at steady state

- Minimal wash buffer consumption of <1.0 liter per 8 hours of operation

- Minimal air turbulence virtually eliminates sample evaporation during printing

- Vibration dampeners allow high printing quality in any laboratory

- Class 1 cleanroom compatible

- 400+ installations worldwide

- World’s most popular personal microarrayer product line

- Customer Installation time of 1 hour

- Continuous on-line technical support via email and Skype

Quick Installation Guide

1. Wear nitrile gloves at all times when handling your SpotBot® 4.

2. Unpack your shipment and place all items on the lab bench.

3. Place the SpotBot® 4 at the front of the bench and carefully remove the packing material from the instrument compartment.

4. Place the ACM 20 cm directly behind the SpotBot® 4 instrument.

5. Place the computer, LED screen, keyboard, mouse and mouse pad either to the left or right of the SpotBot® 4 instrument.

6. Connect the color-coded ACM fittings (red, white and blue) to the color-coded wash station fittings (red, white and blue).

7. Connect the megasonic transducer wire (PRO and HOT instruments) to the threaded wash station fitting.

8. Connect the green ACM fitting to the 1L Wash Buffer Reservoir and place to the right of the ACM.

9. Connect the yellow ACM fitting to the 1L Wash Waste Container and place it on the floor beneath the SpotBot® 4 instrument.

10. Connect the USB data cable to the back of the computer and SpotBot® 4 instrument.

11. Connect the 12 volt power supply to the back of the SpotBot® 4 instrument.

12. Place the blue anti-vibration pads under the four feet of the SpotBot® 4 instrument.

13. Place the black anti-vibration pads under the four feet of the ACM.

14. Connect the power supply to the back of the ACM and gently tighten the threaded screws.

15. Connect the DVI cable, keyboard, mouse and Ethernet cable to the back of the computer.

16. Connect the other end of the Ethernet cable to an Internet port and the other end of the DVI cable to the LED monitor.

17. Connect the electrical plugs for the SpotBot® 4 power supply and ACM power supply to a 110 volt or 222 volt power strip.

18. Connect the electrical plugs for the computer and LED monitor to a 110 volt or 222 volt power strip.

19. Fill the 1L Wash Buffer Reservoir with 1,000 ml of SpotBot® 4 Wash Buffer.

20. Power on the ACM and make sure wash buffer is filling the wash station inside the SpotBot® 4 instrument.

21. Power on the computer and screen and launch SpotBot® 4 SpotApp software by clicking on the desktop icon.

22. Register your SpotBot® 4 instrument using our secure Ethernet server connection.

23. Use SpotApp to select your test printing routine on the computer desktop.

24. Follow the commands on the screen to run your test printing routine.

25. After 5-10 minutes of the test printing routine, terminate the test print run.

26. Place a 384-well microplate containing 4-8 µl sample per well in the SpotBot® 4 microplate position.

27. Make sure the microplate spring is adding tension against the side of the plate containing well A1.

27. Place 14 glass substrate slides (1 x 25 x 76 mm) on the SpotBot® 4 deck as two columns of 7 slides.

28. Place the L-bracket on the deck to hold the slides in position.

29. Make sure the L-bracket is held in place by the L-bracket spring and is firmly pressing against both slide columns.

30. Launch the SpotApp software and select your test printing routine on the desktop.

31. When printhead moves to the left, open the left door and carefully load 4 x 946MP4 pins into the printhead.

32. Wear nitrile gloves at all times when handling pins and carefully remove the pin caps by pulling straight off before loading into the printhead.

33. Click OK and run the test printing routine to completion.

34. After the print run is complete, inspect the glass slides under a 20-30X microscope to confirm your samples have printed.

35. Contact Arrayit technical support (arrayit@arrayit.com) if you have any questions.

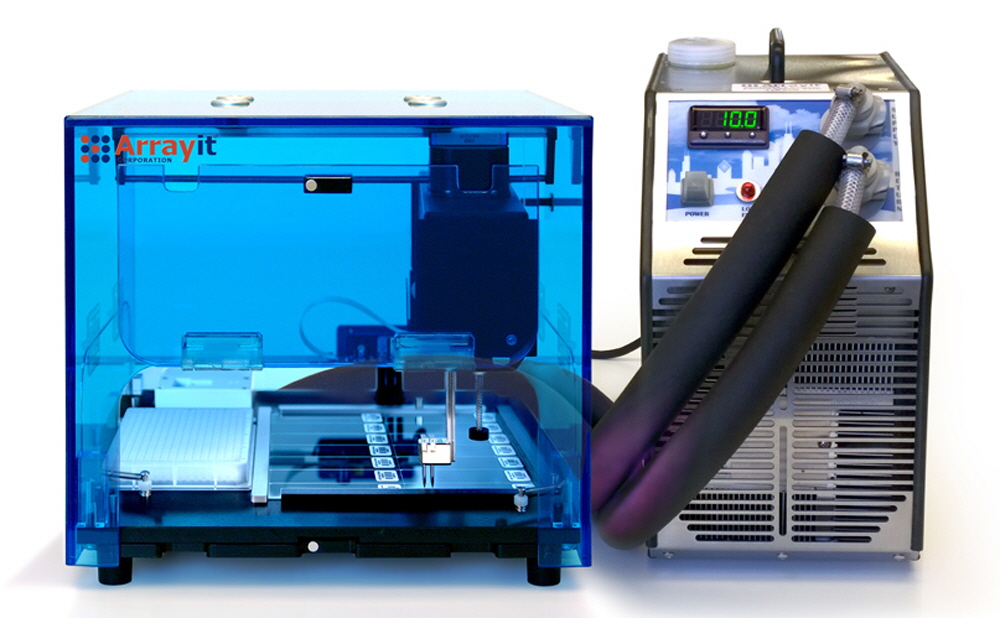

Arrayit SpotBot® 4 Personal Microarrayer with Protein Edition option including custom thermal deck and chiller bath for 4°C to ambient temperature control ideal for protein and reverse phase microarrays. The “HotBot” option permits 4°C to 45°C temperature control for protein microarrays as well as enzyme and whole celll microarrays requiring heating to 37°C.

Table 1. SpotBot® 4 Personal Microarrayer System Components and Options.

System Component |

Description |

Standard |

Option |

SpotBot® 4 Personal Microarrayer |

World’s most popular personal microarray printers featuring compact footprint, micro-robotic motion control, ±10 µm positional resolution, heavy duty gantry, patented contact printing technology, and environment enclosure for completely automated turnkey desktop microarray printing. |

Yes |

|

Contact printing technology |

Arrayit patented contact printing technology covered by US 6,101,946 patent, installed in >4,500 laboratories worldwide, featuring microarray printing pins with defined uptake channel and flat tips for consistent high quality microarray printing. |

Yes |

|

Adjustable spot diameter |

SpotBot® 4 professional series printhead will hold Arrayit’s entire line of Professional, 946 and Stealth microarray printing pins, allowing users to control printed spot diameter from 37.5-560 µm. |

Yes |

|

Instrument enclosure |

SpotBot® 4 instruments include a transparent instrument case that protects against particulate contaminants and allows humidity and temperature control during operation. |

Yes |

|

Compact footprint |

SpotBot® 4 instruments have a highly compact 0.03 cubic meter (1.0 cubic foot) instrument dimensions for market’s most compact microarray printer. |

Yes |

|

Low thermal emission |

SpotBot® 4 instruments utilize advanced micromotors for low thermal emission during operation to ensure the integrity of biological molecules and surface chemistry. |

Yes |

|

Universal biochemistry platform |

SpotBot® 4 patented contact printing technology allows printing of virtually any biomolecule including DNA, protein, small molecule, carbohydrate, lipid, cell extract, whole cells and many other sample types for ultimate flexibility. |

Yes |

|

Wide sample viscosity range |

SpotBot® 4 patented contact printing pins load samples by simple capillary action, which enables the use water, glycerol, and DMSO and other light solvents to accommodate diverse sample types. |

Yes |

|

Low sample volumes |

SpotBot® 4 instruments utilize standard footprint 384-well microplates to allow easy and convenient workflow from sample preparation to microarray printing. Recommended sample volumes are 4-8 µl per 384-well. |

Yes |

|

Highly affordable manufacturing |

SpotBot® 4 patented contact printing pins load 0.25 µl per sample uptake from a recommended sample volume of 4-8 µl per 384-well to allow the use of small sample volumes for highly affordable manufacturing. |

Yes |

|

Gentle delivery mechanism |

SpotBot® 4 patented contact printing pins print samples using a gentle surface tension “ink-stamping” method to ensure the integrity of microarray substrates including membrane coatings and maintain the activity of sensitive printed molecules including proteins and whole cells. |

Yes |

|

Standard glass substrate slide format |

SpotBot® 4 instruments accommodate the industry standard “open platform” 1 x 25 x 76 mm glass substrate slide format for compatability with Arrayit’s complete microarray slide product line. |

Yes |

|

Supports many printing surfaces |

SpotBot® 4 instruments and patented contact printing pins enable printing onto a wide range of different substrates including glass, plastic, silicone and other materials for manufacturing and innovation flexibility. |

Yes |

|

Rapid pin replacement |

SpotBot® 4 patented contact printing technology allows customers to replace microarray printing pins in real time without any special tooling required to allow easy changes in spot diameter and loading of new pins in cases of pin clogging or damage. |

Yes |

|

110-Volt and 220-Volt System Components |

SpotBot® 4 printers and accessories are compatible with both 110 and 220 volt electrical sources for domestic and international operation at customer locations worldwide. |

Yes |

|

Accessory Control Module |

SpotBot® 4 printers utilize an Accessory Control Module (ACM) with power supply and anti-vibration feet to allow easy and convenient control of instrument peristaltic pump, dry station, humidity control and megasonic wash station. |

Yes |

|

946MP4 printing pins |

Arrayit 946MP4 microarray printing pins, 4 each, featuring 0.25 µl sample channel, 100 µm wide tip and nominal 135 µm diameter printed microarray spots for a wide range of microarray manufacturing applications. |

Yes |

|

946 pin tool |

Arrayit 946 pin tool (inserted in the hole in the pin collar) is used to remove 946MP4 and other 946 style microarray printing pins from the printhead to allow pin cleaning and loading different pin types. |

Yes |

|

Calibration test pin |

SpotBot® 4 microarray printers include 1 calibration test pin (Cat. SSP015) with a solid 375 µm wide tip for testing new printing routines before running the instrument with the more expensive 4 x 946MP4 pins in the printhead. |

Yes |

|

Wash buffer container |

SpotBot® 4 microarray printers include a portable 1 liter wash buffer container to allow customers to easily monitor and replace wash station wash buffer during instrument operation. |

Yes |

|

Wash waste container |

SpotBot® 4 microarray printers include a portable 1 liter wash waste container (placed on the floor below the instrument) to allow customers to easily collect and discard used wash buffer produced by the wash station during instrument operation. |

Yes |

|

SpotBot® 4 wash buffer |

SpotBot® 4 microarray printers include 1 liter of 1X wash buffer to fill the wash buffer container prior to instrument operation. Wash buffer is pumped through the wash station by the ACM peristaltic pump and cleans the microarray printing pin tips during the printing process. |

Yes |

|

Substrate locator |

SpotBot® 4 microarray printers include an “L-shaped” L-bracket to hold the 14 substrate slides (1 x 25 x 76 mm) on the deck of the instrument during the printing process. The substrate locator is placed on the right side of the instrument deck between the 2 x 7 array of substrate slides and the substrate locator tensioner spring. |

Yes |

|

Substrate slides |

SpotBot® 4 microarray printers include one box of 25 SuperEpoxy 2 or SuperEpoxy 3 substrate slides (1 x 25 x 76 mm) to enable customers to print DNA and protein microarrays immediately upon setting up their instrument. Substrate slides are held in position on the deck using the substrate locator. |

Yes |

|

Anti-vibration pads |

SpotBot® 4 microarray printers include 4 anti-vibration pads (placed under each of the 4 instrument feet) to absorb vibrations on the laboratory bench and improve the precision of the printing process. |

Yes |

|

384-well microplates |

SpotBot® 4 microarray printers include two 384-well microplates (Cat. MMP384) placed on the left side of the instrument deck between the microplate tensioner spring and microplate locator. SpotBot® 4 printing pins (4 each) transfer samples from the microplate onto the substrate slides during the printing process. |

Yes |

|

Print buffer |

SpotBot® 4 microarray printers include one 50 ml bottle of 2X Micro Spotting Solution Plus (Cat. MSP), which is mixed 1:1 volume to volume with DNA samples and transfered into the 384-well microplate for printing. One 50 ml bottle of 2X Protein Printing Buffer (Cat. PPB) is provided with Protein and “HotBot” Edition SpotBot® 4 systems. |

Yes |

|

Data cable |

SpotBot® 4 microarray printers include one USB data cable to transmit instrument commands between the computer and instrument. The USB connects to the back of SpotBot® 4 instrument next to the power supply port. |

Yes |

|

Power supply |

SpotBot® 4 microarray printers include a power supply and voltage-appropriate power to provide electrical power to the instrument during operation. The power supply converts 110 volt or 220 volt power into a lesser voltage to run the instrument. |

Yes |

|

Personal computer |

SpotBot® 4 microarray printers include a BioBlue Mini Computer with pre-installed system software and calibration files, LED flat panel display, DVI cable, keyboard, mouse, mouse pad, wireless antenae, Internet cable and voltage-appropriate power cords. |

Yes |

|

Warranty |

SpotBot® 4 microarray printers include a comprehensive 90-day warranty that covers all system components (except pins and printhead). Additional warranty coverage in one-year increments is available as an option. |

Yes |

|

Extended warranty |

SpotBot® 4 microarray printers optional extended warranty comprehensive coverage on all system components (except pins and printhead). Extended warranty coverage purchased in one-year increments is recommended for most users. |

|

Yes |

Vision System |

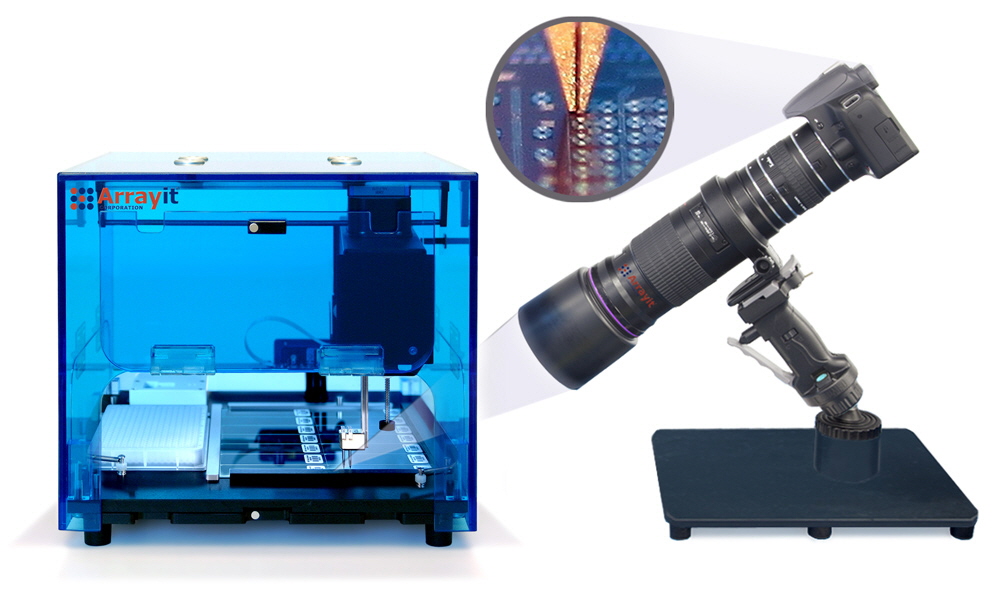

SpotBot® 4 microarray printers offer an optional advanced high resolution Vision System with high-resolution digital camera, tripod, LED illumination source, and custom software interface to view and record absolute positional coordinates on the printing deck with 10 µm spatial resolution for biochip, biosensor, microfluidic and microelectronic applications. |

|

Yes |

Megasonic Wash Station |

SpotBot® 4 microarray printers offer an optional Megasonic Wash Station for enhanced pin cleaning. The Megasonic Wash Station option is included as standard with all Protein and “HotBot” Edition systems. |

|

Yes |

Humidity Control |

SpotBot® 4 microarray printers offer optional Humidity Control for ambient to 80% relative humidification to reduce sample evaporation during printing and for operation in geographical regions with low humidity. The Humidity Control option is included as standard with all Protein and “HotBot” Edition systems. |

|

Yes |

Dehumidification |

SpotBot® 4 microarray printers offer optional Dehumidification for ambient to 10% relative humidification for operation in geographical regions with high humidity. The Dehumidification option is included as standard with all Protein and “HotBot” Edition systems. |

|

Yes |

SpotBot® 4 Protein Edition |

SpotBot® 4 Protein Edition Personal Microarrayers are designed for a wide range of protein, reverse phase and whole cell microarray applications. Protein Edition systems include all of the standard features listed above plus custom temperature-controllable instrument deck, chiller bath (4°C to ambient) with insulated tubing assembly, voltage-appropriate power cord, cooling liquid (3 liters), Megasonic Wash Station, Humidity Control and Dehumidification. |

|

Yes |

SpotBot® 4 HotBot Edition |

SpotBot® 4 HotBot Edition Personal Microarrayers are designed for a wide range of protein, reverse phase, whole cell and enzymatic microarray applications. HotBot Edition systems include all of the standard features listed above plus custom temperature-controllable instrument deck, chiller and heater bath (4°C to 45°C) with insulated tubing assembly, voltage-appropriate power cord, cooling and heating liquid liquid (3 liters), Megasonic Wash Station, Humidity Control and Dehumidification. |

|

Yes |

Scientific Publications

Click on the links to find more than 300 scientific publications featuring Arrayit SpotBot® Personal Microarrayers.

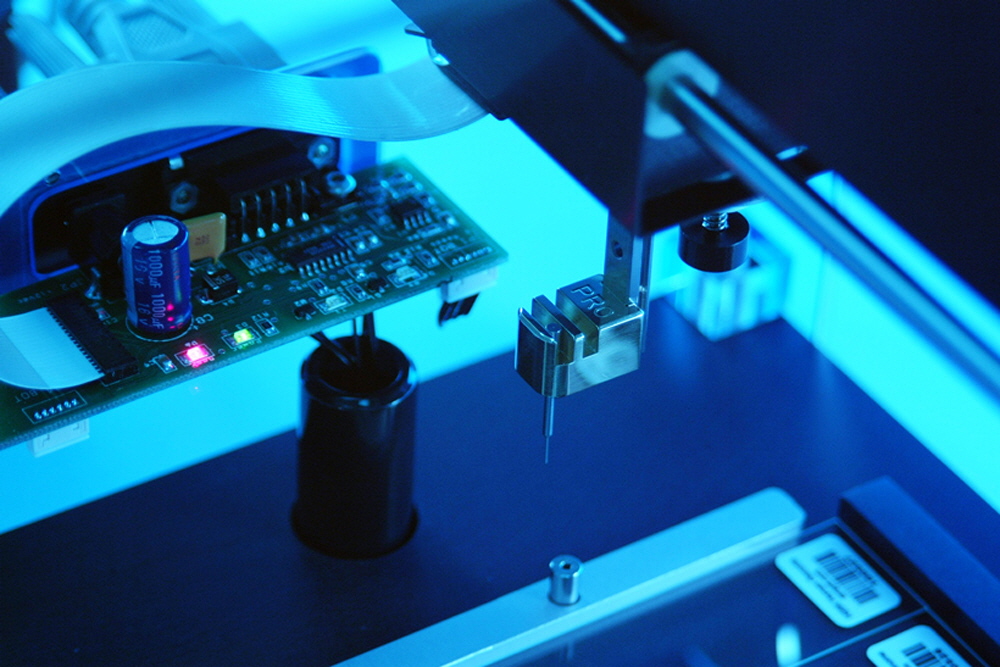

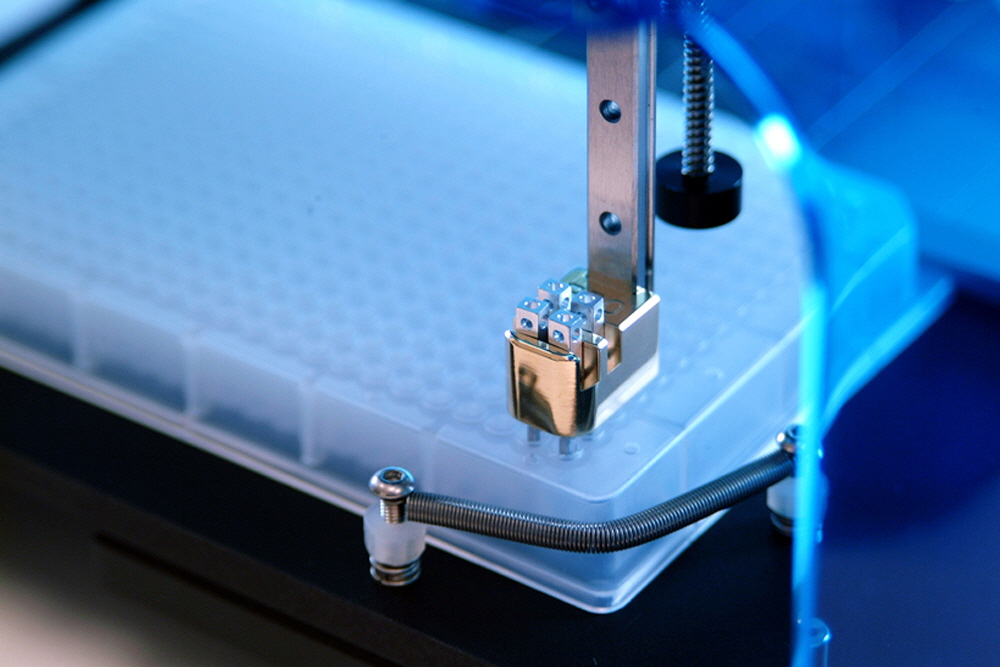

Figure 1. SpotBot® 4 Personal Microarrayer in the home€ position. The printed circuit board (middle left) enables fully automated computer-control. The professional printhead (center) contains a calibration pin in the first of 4 pin apertures.

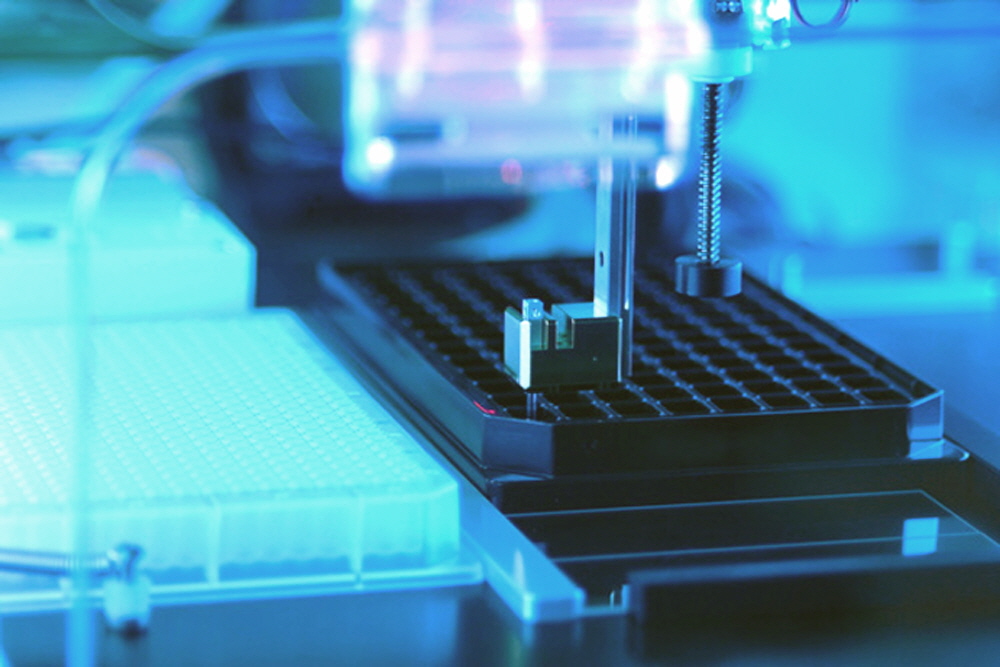

Figure 2. SpotBot® 4 wash station uses wash buffer from the ACM peristaltic pump to clean the 4 pins during printing. The optional megasonic wash station transmits megasonic waves through the wash buffer for enhanced pin cleaning. The dry ports to the right of the wash station use pressurized air from the ACM air compressor to dry the pins after the wash steps.

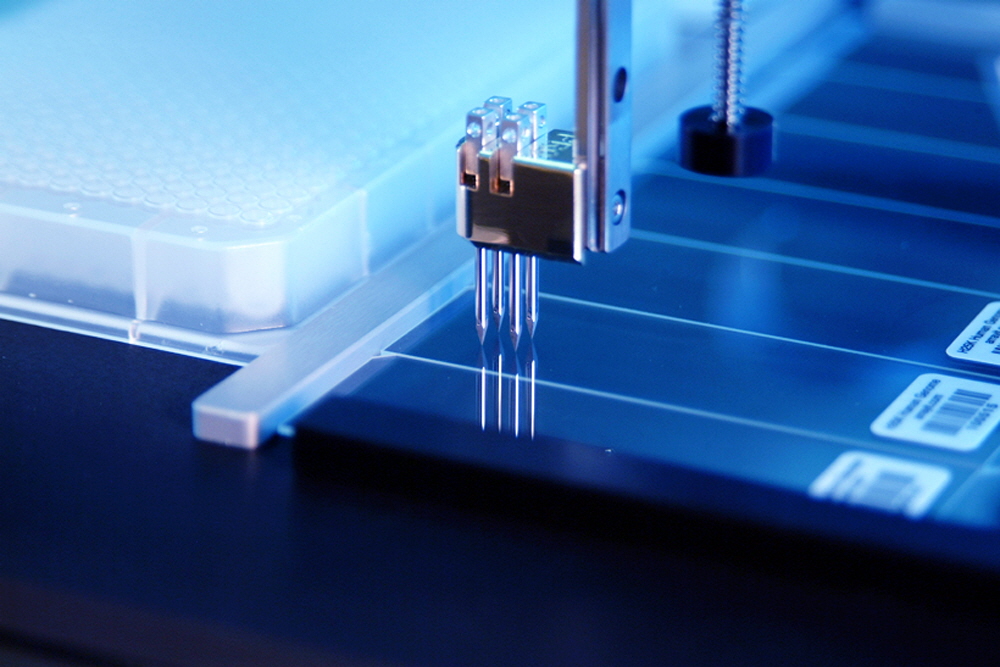

Figure 3. SpotBot® 4 in the sample loading position. The professional series printhead and four 946MP4 microarray printing pins load the first group of 4 wells in the 384-well microplate. Each pin loads 0.25 µl of sample from each well containing a 5 µl total sample volume

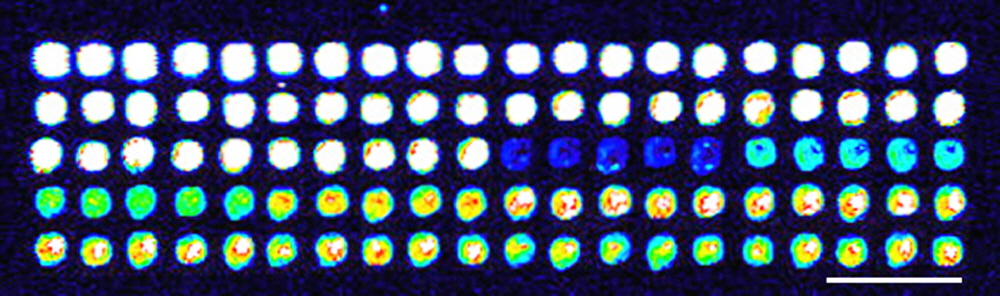

Figure 4. SpotBot® 4 Protein Edition Microarrayer printing dilutions of ArrayIt® Green540 and Red640 fluorescent dyes with four 946MP4 pins and a professional series printhead. Samples were printed in quintuplicate at 200 µm spot spacing. The uniformity of the rows and columns of printed spots reveals the excellent printing performance of the SpotBot® 4. Space bar = 500 µm.

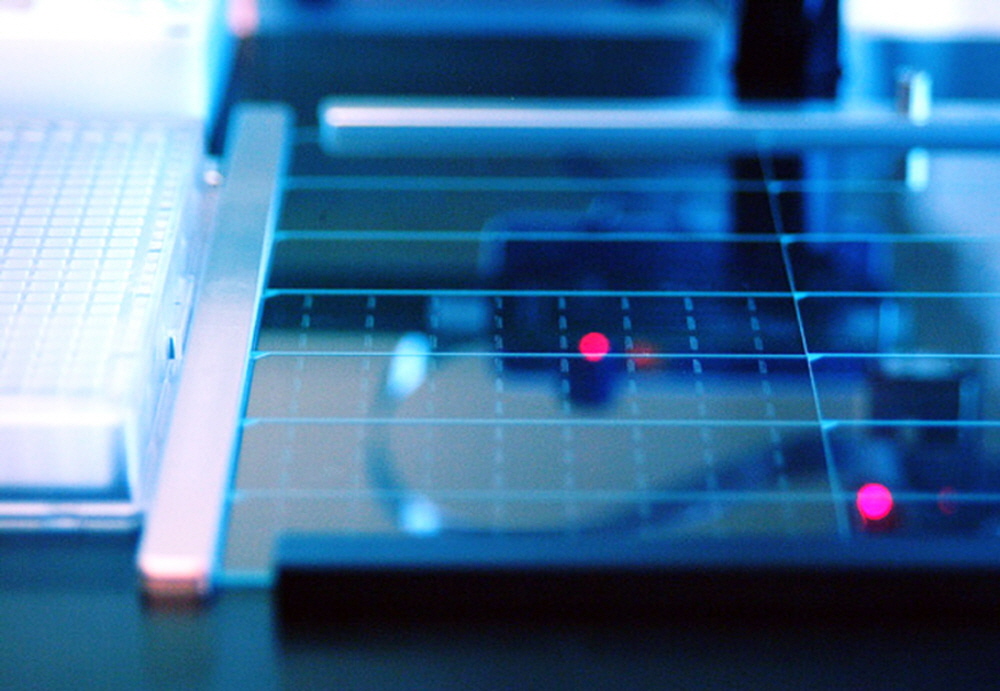

Figure 5. SpotBot® 4 Personal Microarrayer printing multiple microarrays per substrate slide using one 946MP4 microarray printing pin at 175 µm spot spacing printing on SuperAmine (Cat. SMM) microarray substrate slides. A total of 24 microarrays per substrate were printed using the Multiple Microarray Format SpoCLe Generator version 1.1.02 downloadable at http://spotsupport.com.

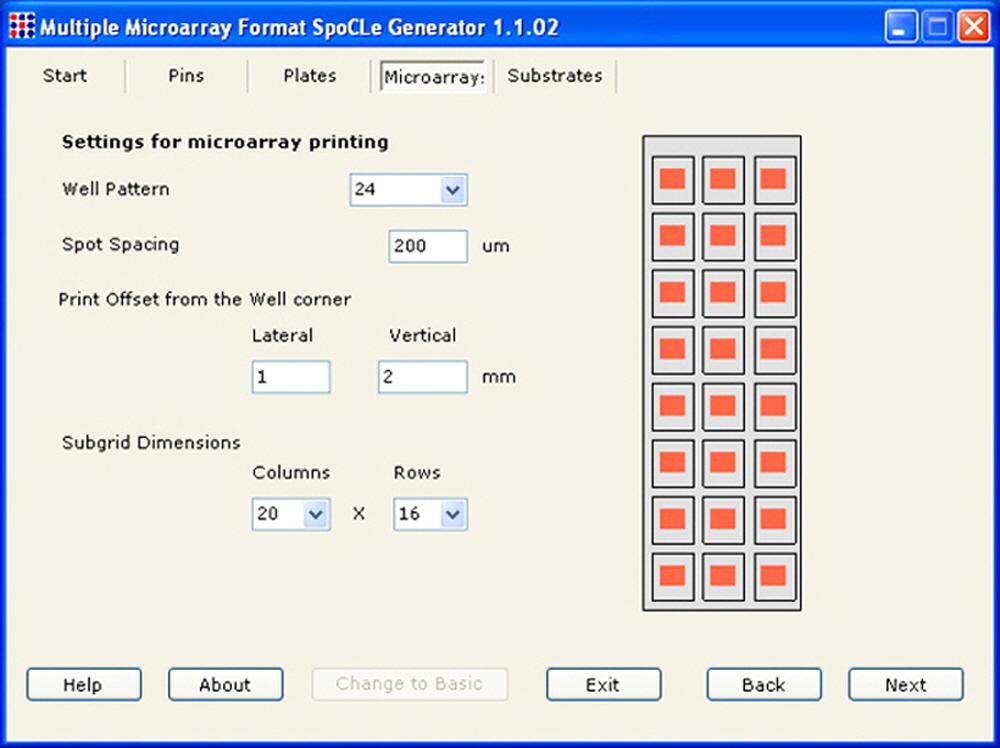

Figure 6. SpotBot® 4 Personal Microarrayer Multiple Microarray Format SpoCLe Generator version 1.1.02 allows the printing of multiple microarrays per substrate. The user selects the well pattern (number of microarrays), spot spacing in microns, print offsets in millimeters, and subgrid dimensions as columns and rows. The software then generates a graphic showing how the printed microarrays (orange icons) will appear on the substrate slides. The Multiple Microarray Format SpoCLe Generator version 1.1.02 is downloadable at http://spotsupport.com.

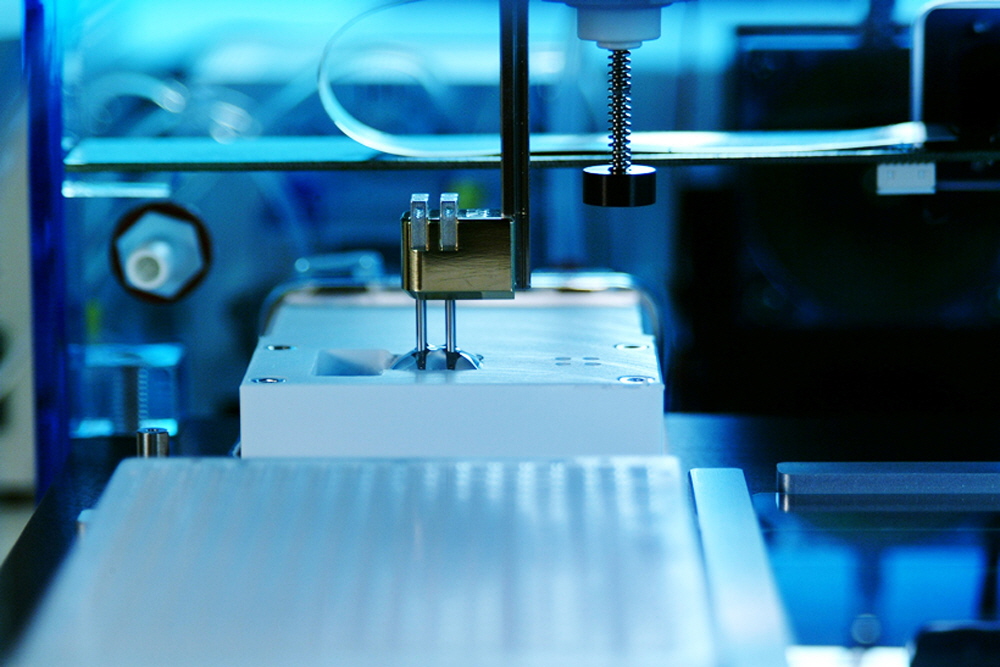

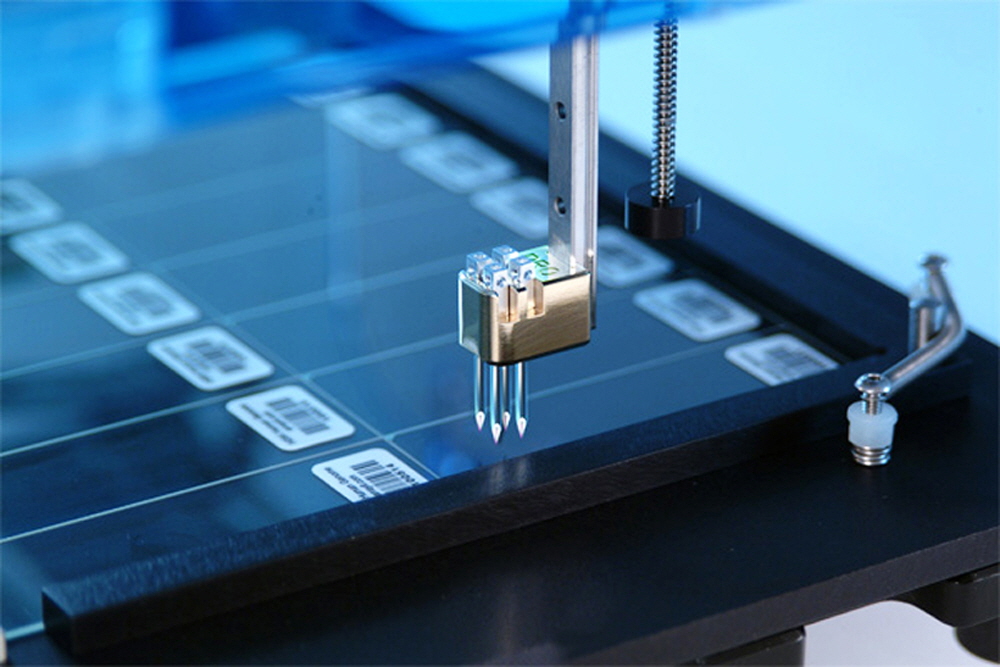

Figure 7. SpotBot® 4 Personal Microarrayer professional series printhead and four 946MP4 microarray printing pins shown in the printing position on the instrument deck. An overtravel distance of 0.5 mm is used to ensure efficient printing onto each glass substrate slide. The SpotBot® 4 Protein Edition option allows deck cooling from ambient to 4°C to enhance the stability of printed proteins, reverse phase protein microarray (RPPA) extracts, and other sensitive samples. The SpotBot® 4 HotBot Edition option allows deck cooling and heating from 4°C to 45°C to enhance the stability of printed proteins, reverse phase protein microarray (RPPA) extracts, and enable enzymatic and whole cell applications requiring 37°C deck heating.

Figure 8. SpotBot® 4 printing into a 96-well glass bottom microplate using software downloadable at www.spotsupport.com. Microplate printing requires the microplate L-bracket locator (Cat. MLS) to hold the microplate and two pre-print substrate slides in postion during printing. System calibration is required prior to initiating microplate printing. Please do not attempt microplate printing without system calibration.

Figure 9. SpotBot® 4 Personal Microarrayer with a pofessional series printhead and four 946MP4 microarray printing pins in the safe Z position over the glass substrate slides. The substrate locator L-bracket immobilizes the substrate slides on the platen during printing using the substrate tensioner spring (middle right).

Figure 10. SpotBot® 4 Personal Microarrayer Vision System with high-resolution digital camera, tripod, and custom software interface to view and record absolute positional coordinates on the printing deck. The Vision System allows visualization of microscopic substrate elements such as 100 µm microelectrodes (see insert) using a digital camera with 10 µm spatial resolution. This option is highly recommended for aerospace, bio-engineering and material science applications.

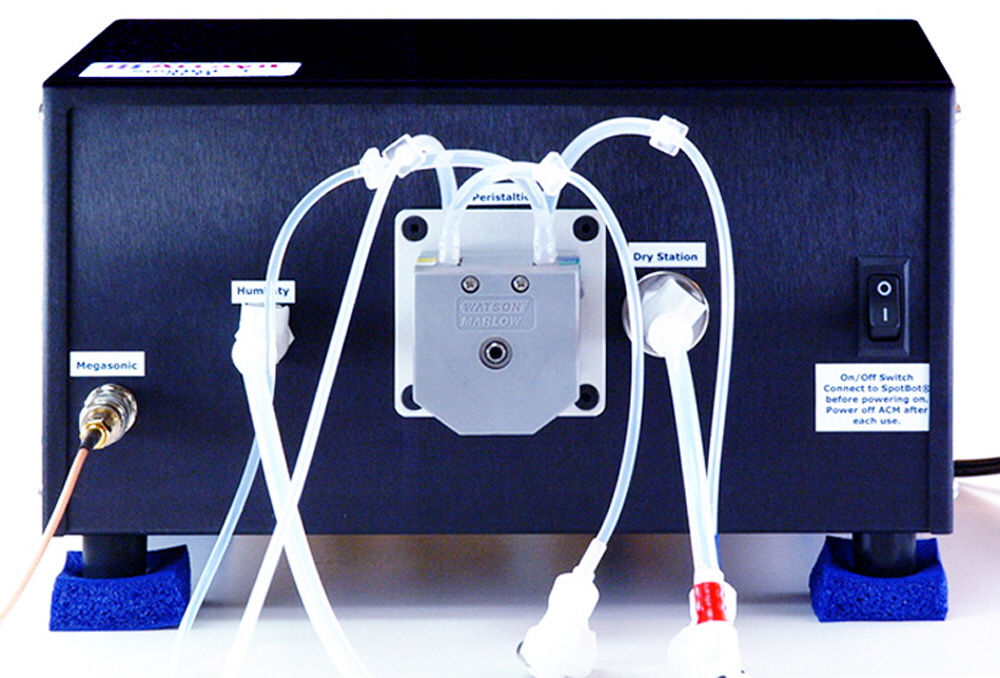

Figure 11. SpotBot® 4 Personal Microarrayer Accessory Control Module (ACM) including connections from left-to-right for the megasonic wash station, humidty control, peristaltic pump, pin drying station, power switch and ACM power supply (rear left). The megasonic cable should be connected to the threaded connector on the wash station and the peristaltic and dry station connections are color-coded as follows: peristaltic wash buffer inward flow to 1 liter wash buffer reservoir (green-green), peristaltic wash buffer inward flow to wash station inward flow (white-white), peristaltic wash waste outward flow to wash station outward flow (blue-blue), peristaltic wash waste outward flow to 1 liter wash waste container (yellow-yellow), and dry station forced air stream to dry station pin drying port (red-red). ACM anti-vibration pads should be placed under the 4 ACM feet as shown. Connect all ACM connections to the SpotBot® 4 prior to powering on the ACM and power off the ACM after each use. The SpotBot® 4 software should be launched prior to powering on the ACM to prevent software complications arising from power surges.