SpotBot® 3

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarrayers - SpotBot® 3 Desktop Personal Microarrayers

Datasheets - PDF's

Spotbot 3 Software Manual

Spotbot 3 User Manual

Spotbot 3 Vision Manual

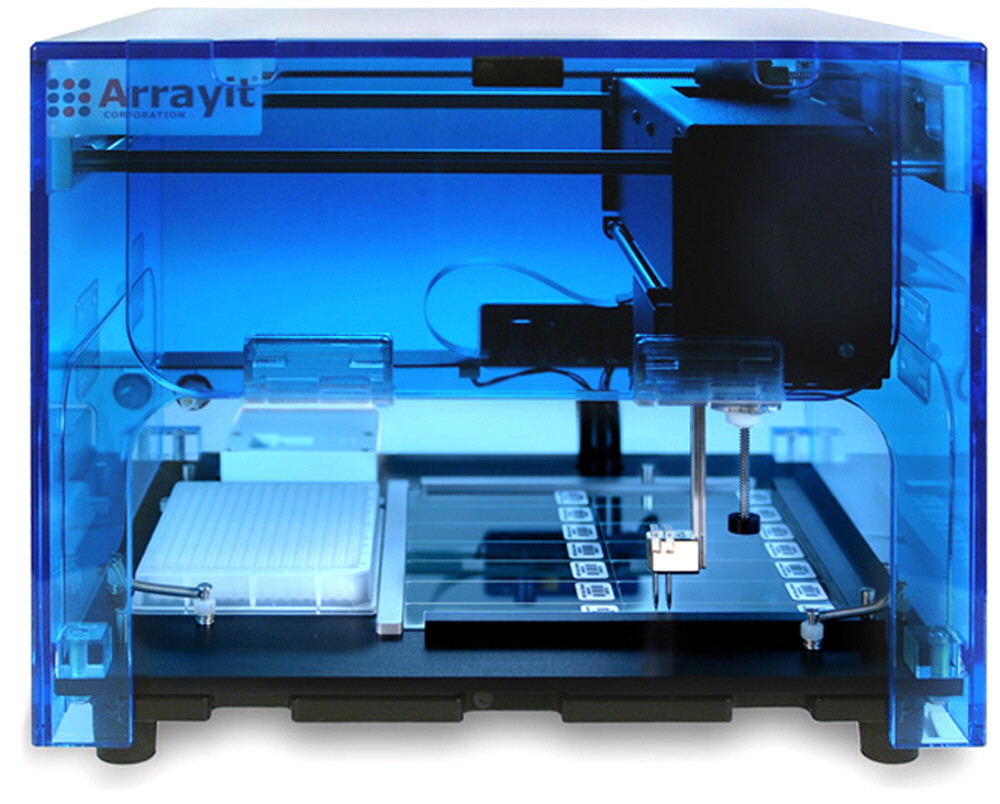

SpotBot® 3 Personal Microarrayers represent the latest technological advance in the highly cited Arrayit SpotBot® product line, installed in more than 380 institutions worldwide. A heavy duty gantry, professional series printhhead, new software, Vision System, and Protein and “HotBot” editions are among the latest features offered by SpotBot® 3 instruments. Customers can leverage our patented contact printing technology to produce diverse DNA, protein, reverse phase and whole cell microarray content in personal desktop designs that offer precision, compactness and affordability. SpotBot® 3 Personal Microarrayers are the ultimate automated solution to innovative microarray research, genomics, proteomics and diagnostics, and are essential equipment for a growing number of life science and healthcare laboratories.

The SpotBot® 3 Protein Edition (SPA3PRO) includes a high-performance chiller bath for rapid and accurate cooling of the entire printing deck from ambient down to 4ºC. A pair of 2-meter (6 ft.) insulated coolant flow tubes allow convenient storage of the chiller bath beneath the bench, to maximize benchtop efficiency and workspace utilization. SpotBot® 3 ”HotBot” Edition Microarrayers (SPA3HOT) includes a high-performance Peltier heating unit for rapid and accurate heating of the entire printing deck from ambient to 45ºC. Chiller and heating units may differ in appearance from the unit shown here based on system requirements and availability.

SpotBot® 3 System Specifications and Features

- SpotBot® 3 instruments represent a significant advance over earlier instruments

- Heavy duty gantry offers improved precision, speed and durability

- Arrayit patented contact printing technology (U.S. 6,101,946) adds confidence

- SpotBot® 3 Vision System option allows high-resolution pin location viewing

- 4-pin printhead configuration in a 2 x 2 pattern at 4.5 mm spacing

- Professional series printhead for reduced friction and unsurpassed printing precision

- Axis resolution and repeatability of ±10 µm

- Deck accommodates 14 standard glass substrate slides (25 x 76 mm)

- Deck accommodates 1 microplate (384-well)

- Complete deck and microplate cooling from ambient to 4°C for Protein Edition

- Complete deck and microplate heating from ambient to 45°C for “HotBot” Edition

- Humidity control option from 10-80% RH

- Megasonic Wash Station option enhances pin cleaning

- Compatible with all Stealth and 946 Micro Spotting Pins

- Printing routines allow 1-5 technical replicates per sample

- 3,600 spots per sub-microarray (9 x 9 mm)

- 50,400 spots per entire substrate (18 x 63 mm)

- Printing time of 2 hrs per 384-well microplate

- >1,000 samples in 6 hours

- Compatible with Windows 2000 and XP Pro (Windows 7 beta version available)

- Power requirements: Standard 120-volt or 220 volt outlets

- Ease-of-operation via new version 3 Graphical User Interface (GUI)

- Robot size (H x L x W): 22 cm (8.7 in) x 30 cm (11.8 in) x 30 cm (11.8 in)

- Robot weight: 6.4 Kg (14 lbs) including vacuum and peristaltic pumps

- Private label and OEM agreements available

- World’s only truly portable microarrayers, volume = 1.0 ft3

- World’s only turnkey desktop protein microarray manufacturing system

- Create a miniature “cold room” on your desktop with Protein Edition Systems

- Flow-through platen cooling maximizes chilling uniformity

- Systems arrive pre-calibrated and ready to use

- Micro-robotics enable efficient motion control

- “Zero” thermal emission, ultra-low energy consumption, and quiet operation

- Forced air stream pin drying eliminates sample carry-over

- Humidity control of 5% per minute and ±1 % at steady state

- Minimal wash buffer consumption of <1.0 liter per 8 hours of operation

- Minimal air turbulence virtually eliminates sample evaporation during printing

- Vibration dampeners allow high printing quality in any laboratory

- class 1 cleanroom compatible

- 382 installations worldwide

- World’s most popular personal microarrayer product line

- Customer Installation time of 1 hour

Scientific Publications

Click on the links to find more than 300 scientific publications featuring Arrayit SpotBot® Personal Microarrayers.

Table 1. SpotBot® 3 System Components and Options.

System Component |

SpotBot® 3 Personal Microarrayer Cat. SPA3 |

SpotBot® 3 Personal Microarrayer Complete Cat. SPA3XP |

SpotBot® 3 Personal Microarrayer Protein Edition Cat. SPA3PRO |

SpotBot® 3 Personal Microarrayer Protein Edition Complete Cat. SPA3PROXP |

SpotBot® 3 Personal Microarrayer ”HotBot” Edition Cat. SPA3HOT |

SpotBot® 3 Personal Microarrayer ”HotBot” Edition Complete Cat. SPA3HOTXP |

SpotBot® 3 Personal Microarrayer |

Yes |

Yes |

|

|

|

|

SpotBot® 3 Personal Microarrayer Protein Edition |

|

|

Yes |

Yes |

|

|

SpotBot® 3 Personal Microarrayer “HotBot” Edition |

|

|

|

|

Yes |

Yes |

110-Volt or 220-Volt System, Customer Specified |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Option |

Option |

Option |

Option |

Option |

Option |

|

Chiller Bath with Insulated Tubing and Voltage-Appropriate Power Cable |

|

|

Yes |

Yes |

|

|

Liquid Coolant, 2 Liters |

|

|

Yes |

Yes |

Yes |

Yes |

Digital Thermometer with Temperature Probe and Thermal Compound |

|

|

Yes |

Yes |

Yes |

Yes |

Air Compressor with Voltage-Appropriate Cable |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Peristaltic Pump with Tubing Set and Voltage Appropriate Power Supply |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Wash Buffer Assembly, 1 Liter |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Wash Waste Container, 1 Liter |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

SpotBot® 3 Wash Buffer, 1 Liter |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Substrate Locator L-Bracket |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Megasonic Power Supply and Wash Station |

Option |

Option |

Option |

Option |

Option |

Option |

Humidity Control Apparatus |

Option |

Option |

Yes |

Yes |

Yes |

Yes |

Dehumidification Apparatus |

Option |

Option |

Yes |

Yes |

Yes |

Yes |

946MP4 Pins (4 Each) and Test Pin |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Custom Pins, 4 Each |

Option |

Option |

Option |

Option |

Option |

Option |

946 Pin Tool |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Anti-Vibration Pads, 4 Each |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

SuperEpoxy 2 Microarray Substrates, 25 Each |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Micro Spotting Solution Plus (50 ml of 2X) |

Yes |

Yes |

|

|

|

|

Protein Printing Buffer, 50 ml of 2X |

|

|

Yes |

Yes |

Yes |

Yes |

384-Well Microplate, Cat. MMP384 |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

COM Cable |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Power Supply, 110-220 Volt |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

BioBlue Mini Computer with pre-installed software, keyboard, mouse and mouse pad |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

LED 20” flat panel display |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Hybridization Cassette |

|

Yes |

|

Yes |

|

Yes |

High-Throughput Wash Station |

|

Yes |

|

Yes |

|

Yes |

Microarray High-Speed Centrifuge |

|

Yes |

|

Yes |

|

Yes |

Technical Notes

1. Calibration Files. SpotBot® 3 Microarrayers are calibrated in our laboratories to ensure proper operation, and the calibration files are pre-loaded onto the system computer prior to shipping. SpotBot® 1 and 2 systems may use calibration files provided on a compact disc (CD). Calibration files are unique to each SpotBot® system and must be installed prior to operating all SpotBot Microarrayers. Please contact technical support (arrayit@arrayit.com) if you have any questions about system calibration.

2. Megasonic Power Supplies and Wash Stations. Megasonic Power Supplies will generate some heat during operation. This is normal. If vibrational waves are visible in the Wash Station, the system is working fine. Please make sure to keep a 10 cm distance between the Power Supply and all other system components to allow proper cooling of the Power Supply by the ambient laboratory environment. Please also remember to maintain at least 2 ml/min buffer flow through the Wash Station at all times as insufficient buffer flow will cause elevated power supply temperatures. Please also remember to power off the power supply after each printing session. The lack of vibrational waves in the Wash Station or excessive Power Supply heating during use may indicate improper function. Please contact technical support (arrayit@arrayit.com) for technical assistance and replacement components.

Software and Instrument Options Links

Click here to view the Standard SpoCLe Generator.

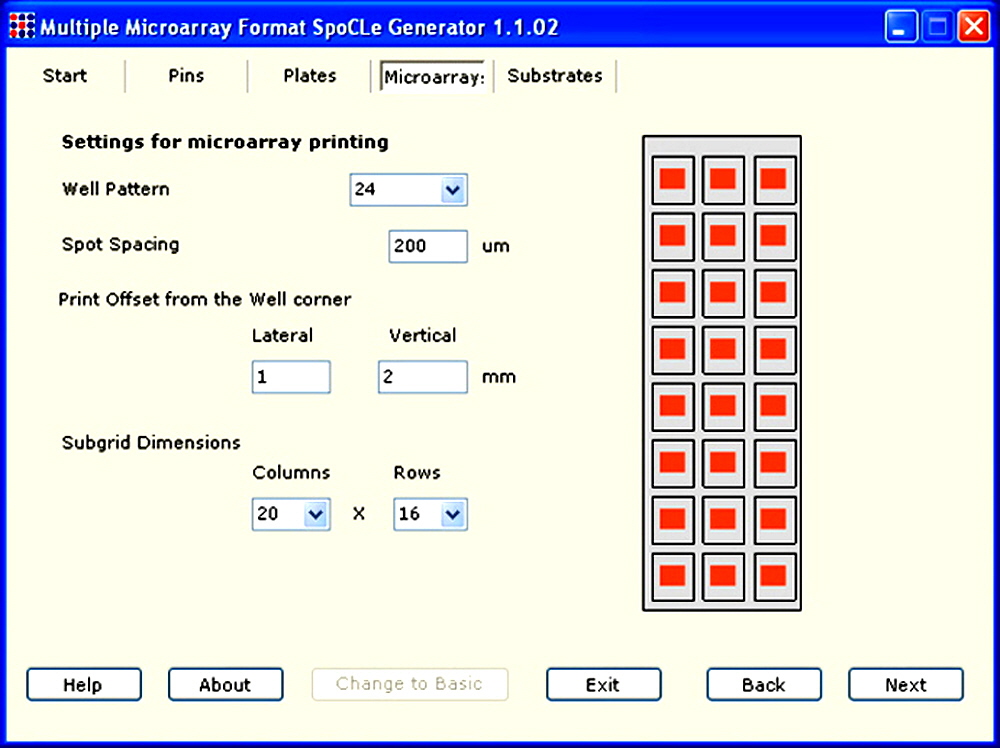

Click here to view the Multiple Microarray SpoCLe Generator.

Click here to view the Biacore SpoCLe Generator.

Click here to view Microplate Printing SpoCle Generator

Click here to view the Megasonic Wash Station.

Click here for assistance with Gal file generation.

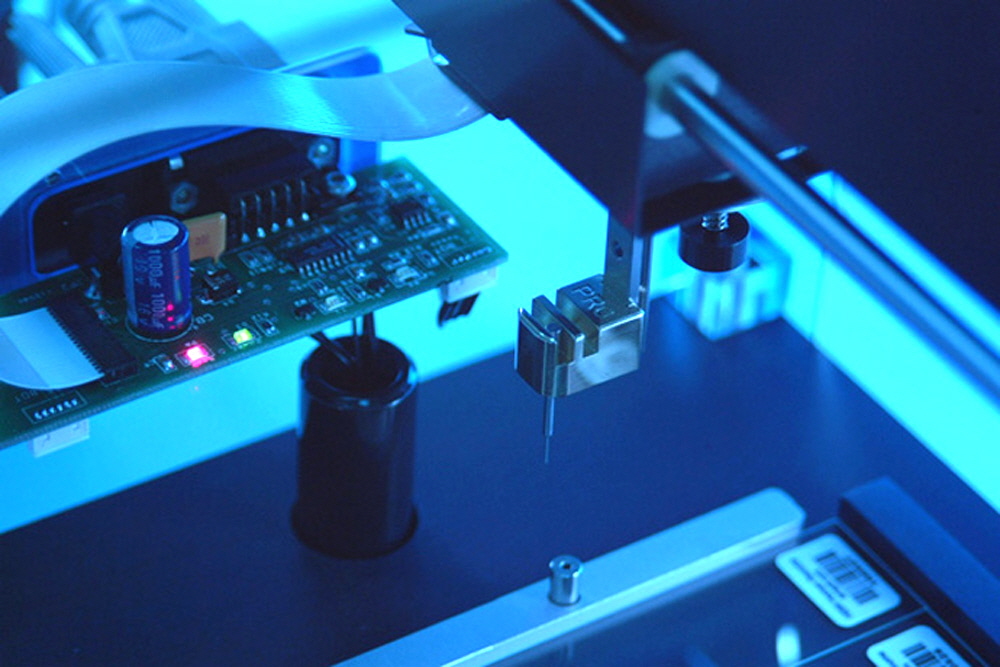

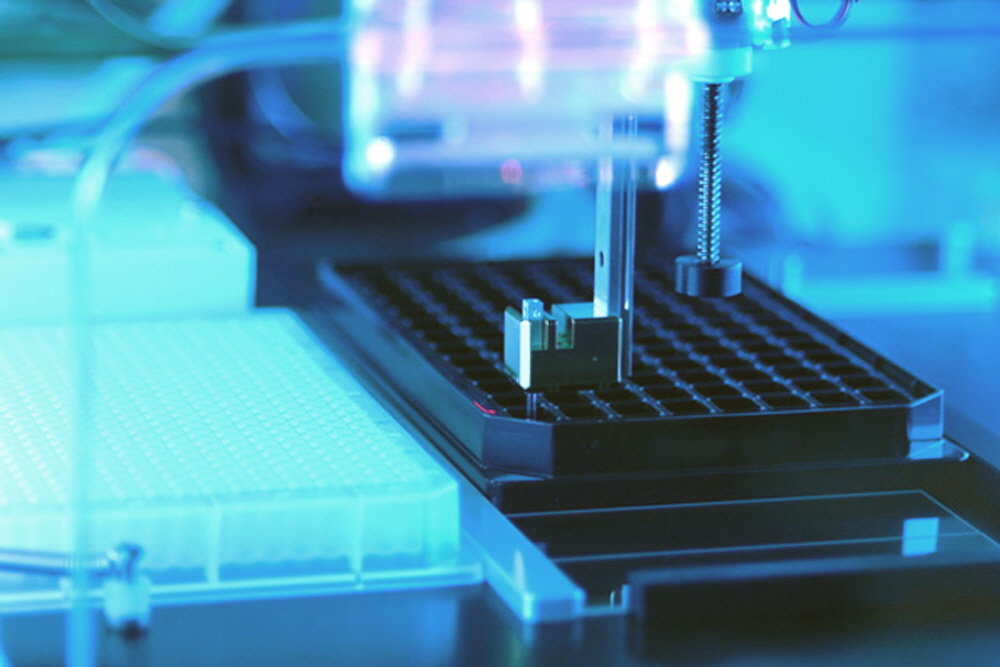

Figure 1. SpotBot® 3 Microarrayer in the “home” position. The printed circuit board and operation lights (top left) permit fully automated computer-control. The professional printhead (center) contains a calibration pin in the first of 4 pin apertures.

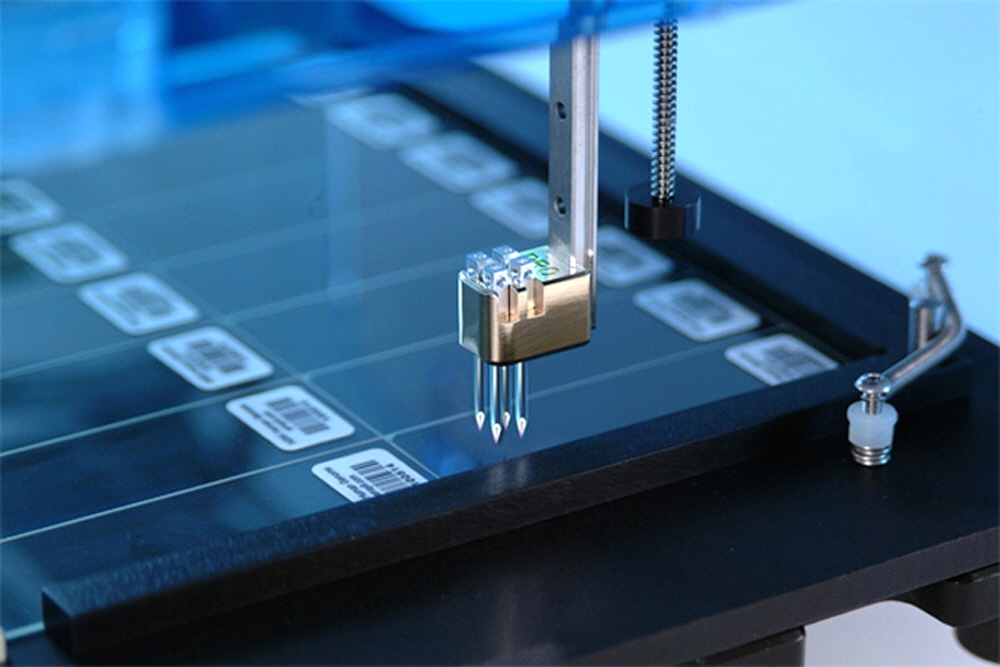

Figure 2. Megasonic Wash Station on the SpotBot® 3 Protein Edition Microarrayer. Megasonic waves propagated through the wash buffer facilitate highly efficient pin cleaning. The dry port to the right of the wash station uses pressurized air to dry the pins after cleaning.

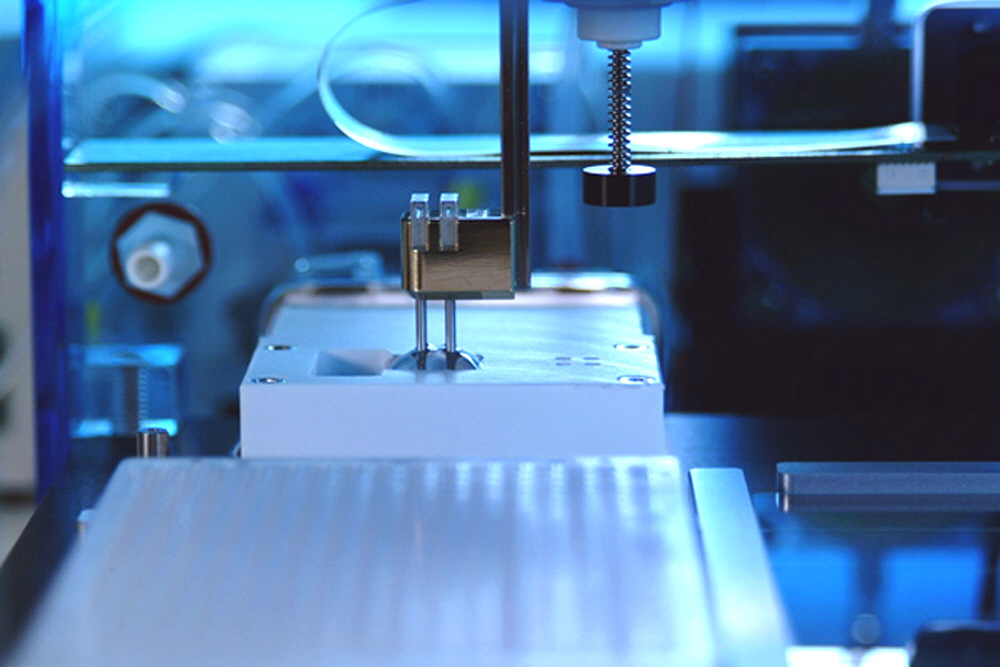

Figure 3. SpotBot® 3 Microarrayer in the sample loading position. The Professional Series Printhead and 4 946MP4 Pins move into the loading position in the first group of 4 wells in the 384-well microplate. A loading time of 3 seconds allows each pin tip to load 0.2 µl of sample from each well containing 5 µl of total sample volume.

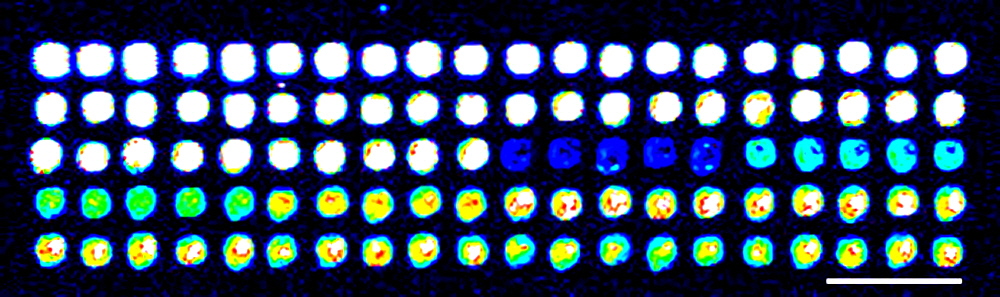

Figure 4. Microarray printed with the SpotBot® 3 Protein Edition Microarrayer. Dilutions of ArrayIt® Green540 and Red640 fluorescent dyes were printed with four 946MP4 Pins and a Professional Series Printhead. All samples were printed in quintuplicate at 200-µm center-to-center spacing. The uniformity of the rows and columns of printed spots reveals the excellent printing performance of the SpotBot® 3 Protein Edition Microarrayer. The space bar denotes 500 µm in the image.

Figure 5. The Humidification System for SpotBot® 3 Personal Microarrayers includes a Humidity Control Compressor, Control Valve, Humidity Chamber, and Temperature and Humidity Pen. The system allows humidification of the internal instrument chamber from ambient to 80% relative humidity (RH) with an accuracy of ±1%. The same core components and instrument port are used for the Dehumidification Apparatus (see Fig. 9).

Advantages of the SpotBot® 3 Protein Edition

Protein microarray experimentation requires the preservation of protein structure at both the sample and printed protein stages. Arrayit SpotBot® 3 Protein Edition Microarrayers feature a proprietary deck and cooling system that provide cooling of the microplate and glass substrate slides down to 4ºC. The result is unsurpassed retention of protein structure and function in ambient laboratory, without the inconvenience of cold room experimentation. Protein Editions systems are particularly well-suited for laboratories studying antigens, antibodies, peptides, cellular extracts and other protein sample types susceptible to room temperature proteolysis.

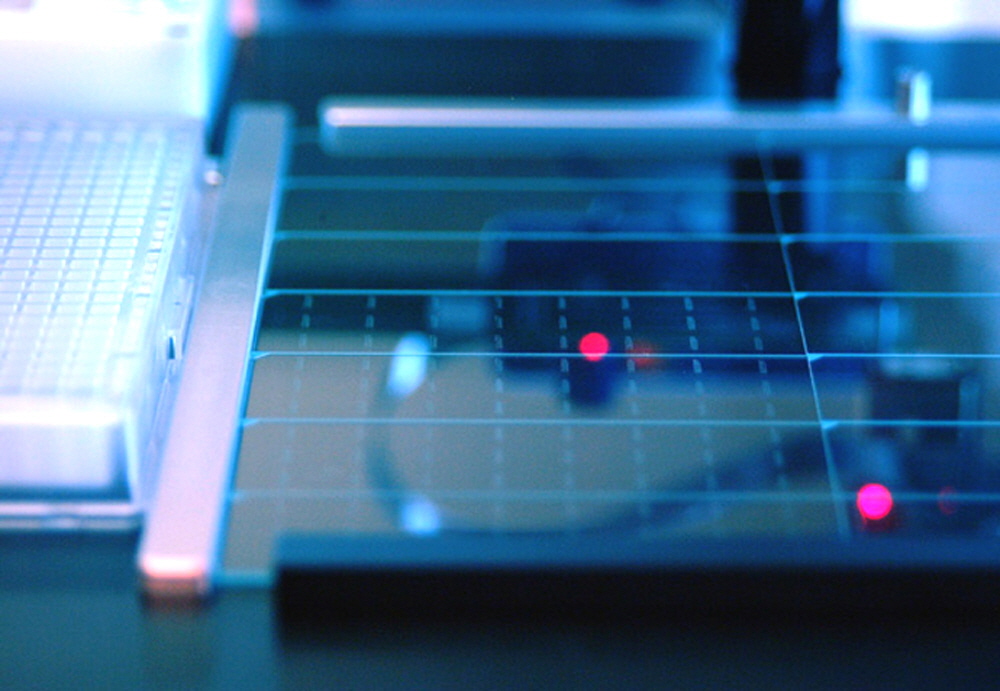

Figure 6. Multiple microarrays per substrate printed with a SpotBot® 3 Personal Microarray Robot. Shown is a photograph of the SpotBot® 3 platen containing SuperAmine Microarray Substrates printed with a SpotBot® 3 Personal Microarrayer running 946MP4 Pins printing at 175 µm spacing. A total of 24 microarrays per substrate were printed using the Multiple Microarray Format SpoCLe Generator version 1.1.02, which can be downloaded at http://spotsupport.com.

Figure 7. Multiple Microarray Format SpoCLe Generator version 1.1.02 allows the printing of multiple microarrays per substrate with SpotBot 2 Personal Microarrayers (see Fig. 6). Shown is a screenshot of the software interface. The user selects the number of microarrays or “well pattern”, spot spacing in microns, print offsets in millimeters, and subgrid dimensions as columns and rows. The software then generates a graphic showing how the printed microarrays (orange icons) will appear on the substrates. The Multiple Microarray Format SpoCLe Generator version 1.1.02 can be downloaded at http://spotsupport.com.

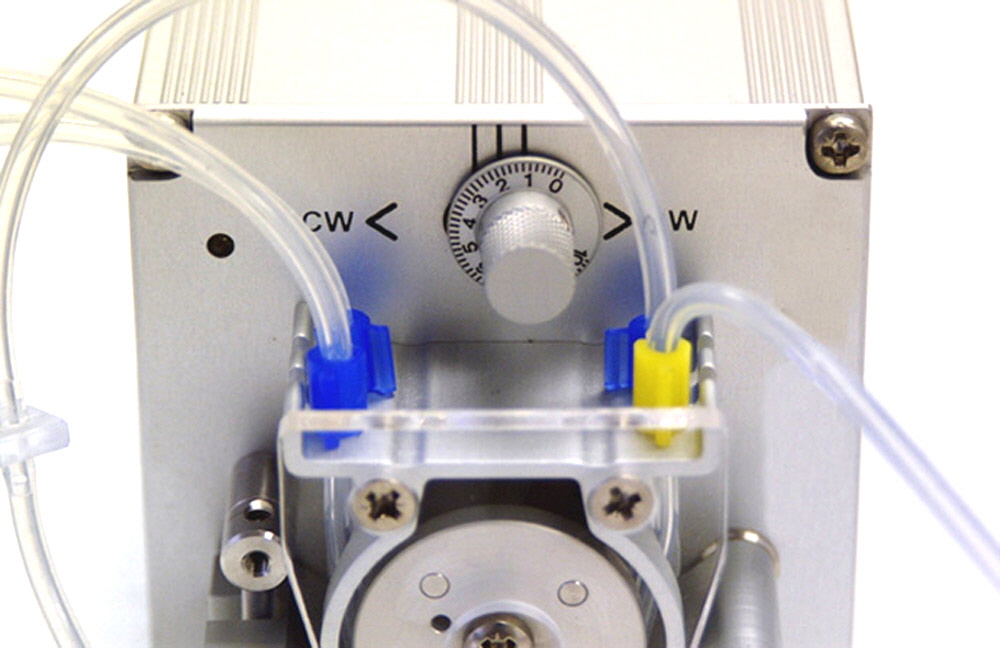

Figure 8. Shown is a photograph of the Peristaltic Pump used on SpotBot®2 Personal Microarrayers. Tubing colors should be configured as shown. The speed dial should be set to the right (CW, clockwise setting) for correct buffer flow into the Wash Station. Pumps are either 12 rpm or 100 rpm as designated on the back of the instrument under “speed”. A proper buffer flow rate of 1.0 ml/min into the SpotBot®2 Wash Station is achieved using dial setting 8 (12 rpm pump) or dial setting 1 (100 rpm pump, shown here). Tubing connections (not shown) should be green-green, blue-blue, yellow-yellow, and white-white as designated on the tubing ends and hardware: green-green = Peristaltic Pump intake to Wash Buffer Reservoir; blue-blue = Peristaltic Pump intake to Wash Station outlet; white-white = Peristaltic Pump outlet to Wash Station intake; yellow-yellow = Peristaltic Pump outlet to Wash Waste Container.

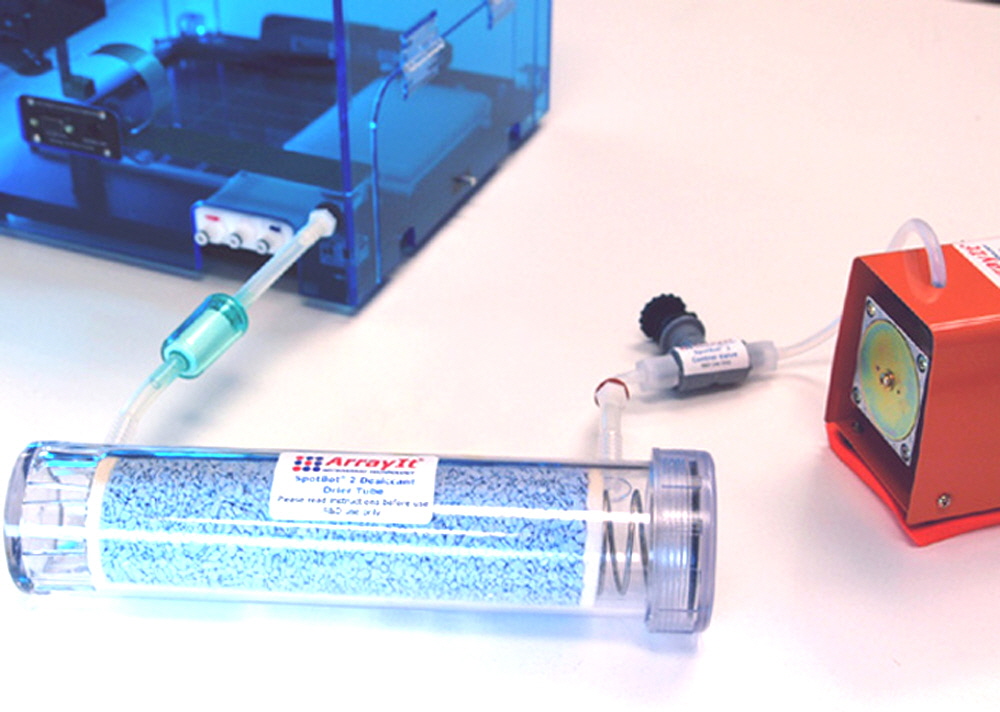

Figure 9. Shown is the Dehumidification Apparatus attached to the correct port on the SpotBot® 3 Protein Edition Personal Microarrayer. The Air Compressor (orange) pushes air through a user-controlled valve and into the desiccant tube. De-humidified air is then filtered (green filter) to remove particulate matter, and propelled under pressure into the SpotBot® 3 instrument. The Dehumidification Apparatus prevents excessive humidity from accumulating when the instrument platen is cooled below ambient temperature. Humidity can be held within 1% of the desired level. The Humidification Apparatus (see Fig. 5) is ported onto the same fitting as the Dehumidification Apparatus.

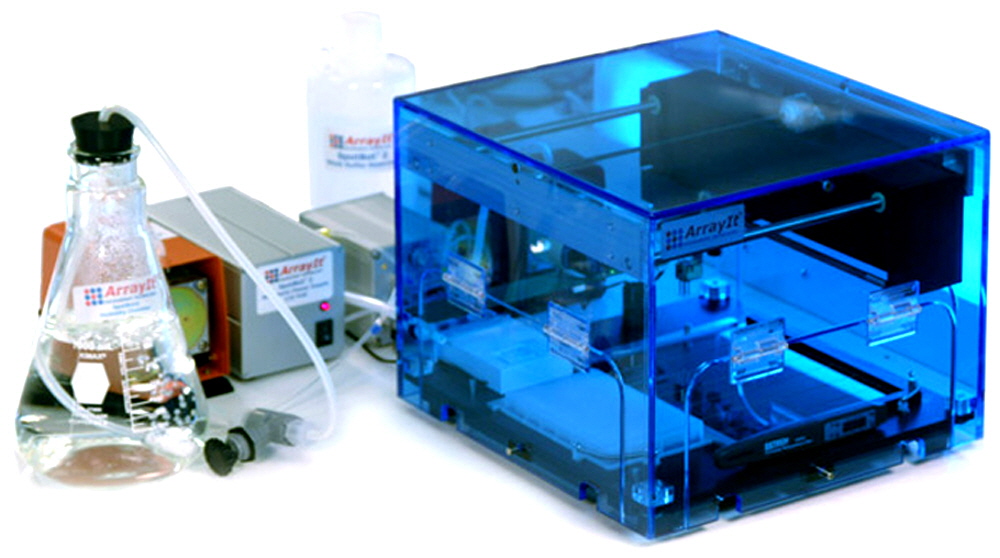

Figure 10. Shown is a photograph of the SpotBot® 3 Microarrayer including the accessories. The translucent wash buffer reservoir, orange air compressor for the dry station, silver peristaltic pump for the wash station, silver megasonic power supply and humidification system including the orange air compressor, humidification reservoir and gray valve are shown correctly configured behind the instrument. The modular and compact accessories improve system utility and performance and simplify maintenance and repair. Inside the instrument, the microplate, L-bracket and temperature/humidity pen are visible. The SpotBot® 3 Protein Edition Microarrayer is configured similarly except that the humidification is replaced by dehumidification (see Figure 9) and a chiller bath is added for deck cooling.

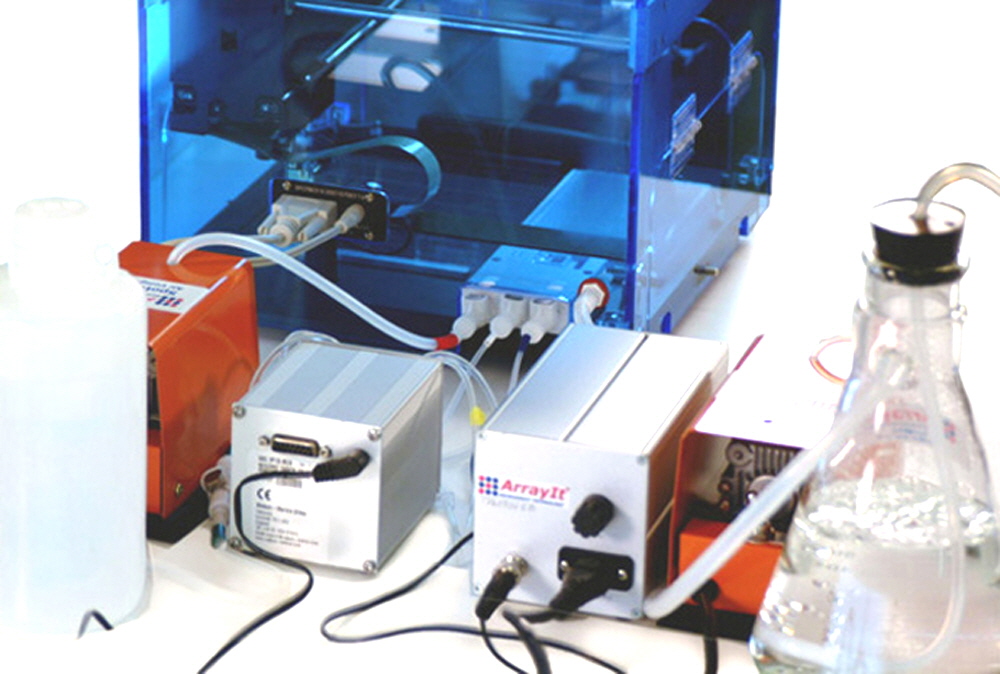

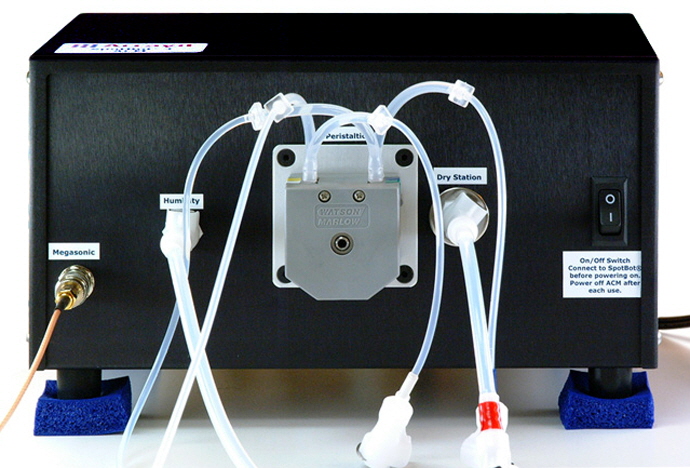

Figure 11. Shown is a photograph of the SpotBot® 3 Personal Microarrayer including the accessories. The translucent wash buffer reservoir, orange air compressor for the dry station, silver peristaltic pump for the wash station, silver megasonic power supply and humidification system including the orange air compressor and humidification reservoir are shown correctly configured behind the instrument. The COM cable, power supply, dry station fitting (red), wash buffer fitting (white), waste buffer outtake (blue), and humidification tubing are shown correctly attached to the back of the instrument. The modular and compact accessories design improves system utility and performance and simplifies maintenance and repair. The SpotBot® 3 Protein Edition Microarrayer is configured similarly except that the humidification is replaced by dehumidification (see Figure 9) and a chiller bath is added for deck cooling.

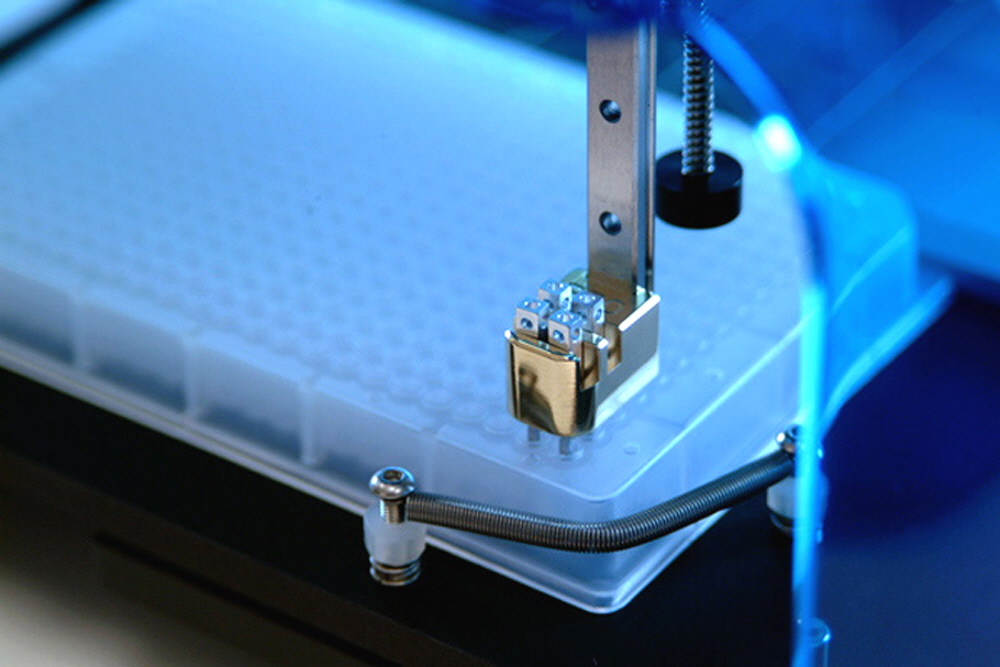

Figure 12. SpotBot® 3 Personal Microarrayer Professional Series Printhead and four 946MP4 Microarray Printing Pins shown in the printing position on the deck. An “overtravel” of 0.5 mm is used to ensure precise printing onto each glass substrate slide. The SpotBot® 3 Protein Edition Microarrayer preserves the activity and integrity of printed samples by cooling the entire deck, including the microplate samples and substrate slides.

Figure 13. SpotBot® 3 Microplate Printing. SpotBot® 3 Protein Edition Personal Microarrayers enable microarray printing into 96-well microplates (shown) and 384-well microplates, as well as onto microplate-sized glass substrates using the standard SpotBot® 3 Protein Edition components and Well Plate Printing Spocle Generator v2.0.2 software running on SpotApp v3.6.0. Microplate printing software is downloadable on the SpotSupport web site. Microplate printing requires the Microplate L-Bracket Locator (Cat. MLS) to hold the microplate in position during printing, and utilizes two pre-print substrates as shown here. System calibration is required prior to printing. Please do not attempt microplate printing prior to system calibration.

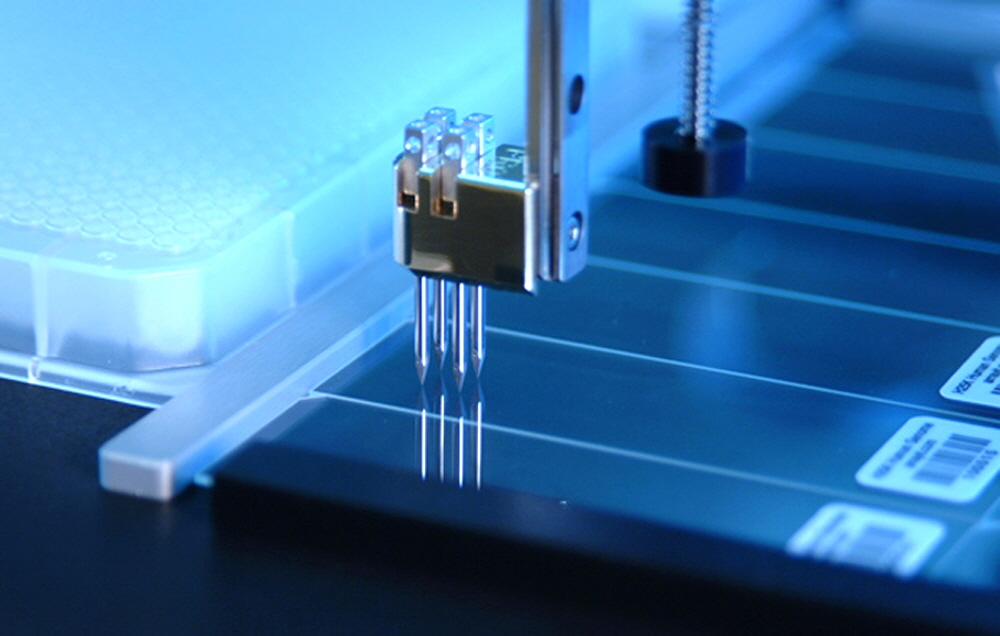

Figure 14. SpotBot® 3 Personal Microarrayer Professional Series Printhead and 946MP4 Printing Pins in the “safe Z” position over the glass substrate slides. The spring-loaded L-Bracket immobilizes the substrate slides on the platen during printing to maintain a high degree of positional precision and accuracy.

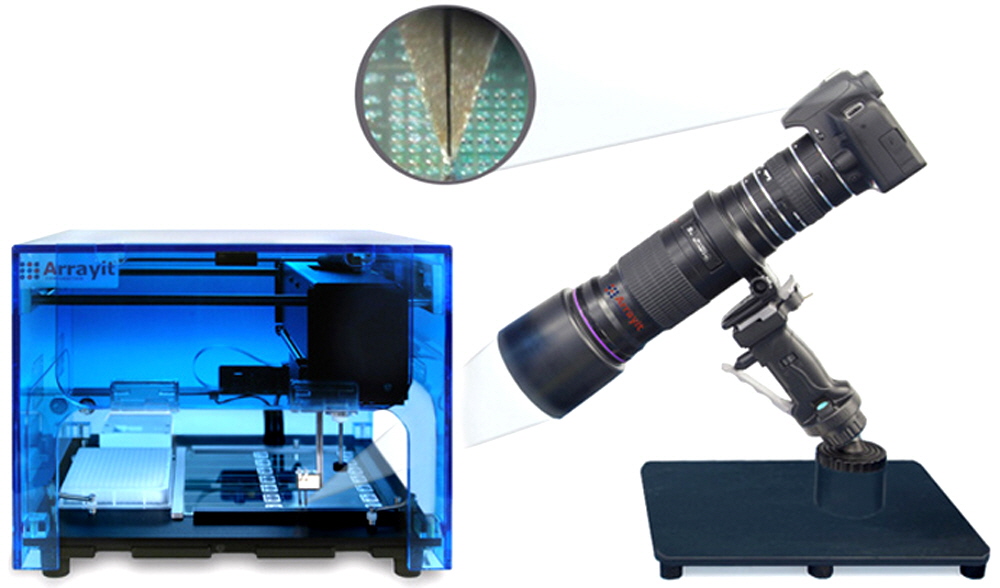

Figure 15. SpotBot® 3 Personal Microarrayer Vision System with high-resolution digital camera, tripod, and custom software interface to view and record absolute positional coordinates on the printing deck. The Vision System allows visualization of microscopic substrate elements such as 100 µm microelectrodes (see insert) using a digital camera with 10 µm spatial resolution. Highly recommended for aerospace, bio-engineering, material science applications.

Figure 16. SpotBot® 3 Personal Microarrayer Accessory Control Module (ACM) including connections from left-to-right for the megasonic wash station, humidty control, peristaltic pump, pin drying station, power switch and ACM power supply (rear left). The megasonic cable should be connected to the threaded connector on the wash station and the peristaltic and dry station connections should be color-coded as follows: peristaltic wash buffer inward flow to 1L wash buffer reservoir (green-green), peristaltic wash buffer inward flow to wash station inward flow (white-white), peristaltic wash waste outward flow to wash station outward flow (blue-blue), peristaltic wash waste outward flow to 1L wash waste container (yellow-yellow), and dry station forced air stream to dry station pin drying port (red-red). ACM anti-vibration pads should be placed under the 4 ACM feet as shown. Connect all ACM connections to the SpotBot® 3 prior to powering on the ACM and power off the ACM after each use.