SpotBot 2

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarrayers - SpotBot® 2 Personal Desktop Microarray Printers

Microplate Printing SpoCLE Generator PDF

Biacore SpoCLE Generator PDF

Standard SpoCLE Generator PDF

325 installations worldwide make SpotBot® the world’s most successful personal microarray manufacturing instrument. Via our patented ex-situ technique, SpotBot can configure virtually any biomolecule into a microarray format.

Click here to watch our SpotBot® Movie!

Click here to watch our SpotBot® technical video.

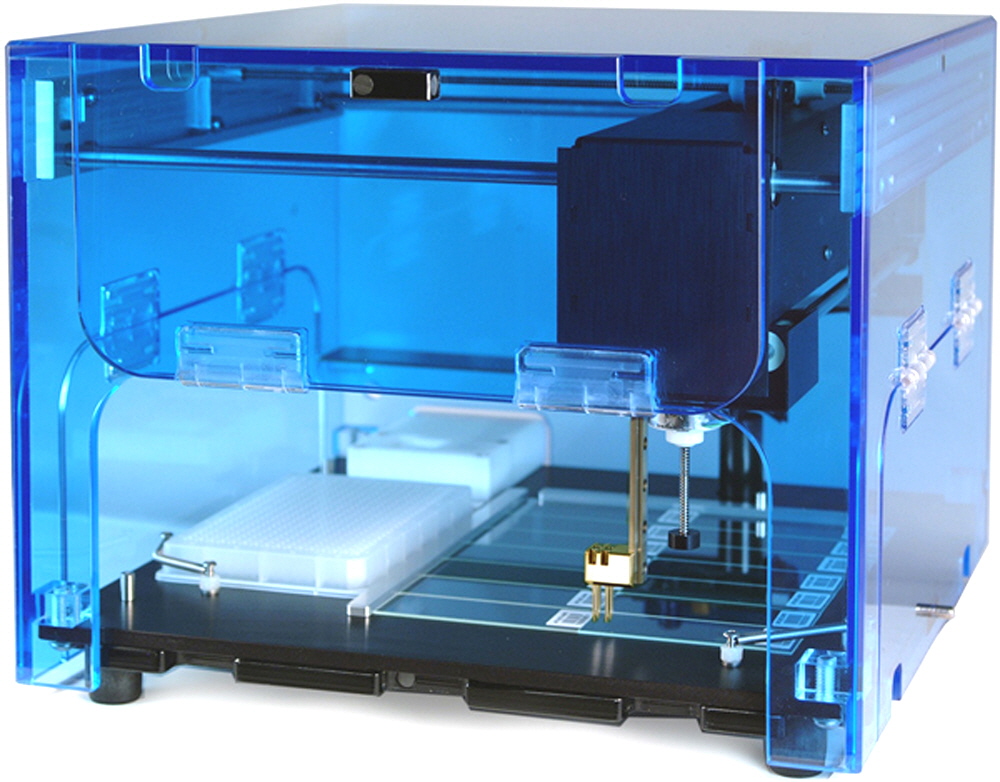

ArrayIt® offers the finest personal microarrayers available, with more than 300 installations worldwide. Our desktop microarray manufacturing instruments use advanced micro-robotics to ensure precision, compactness and affordability. The SpotBot® 2 Personal Microarrayer will print 384 samples onto 14 substrates in duplicate in 2 hours using four patented 946 Micro Spotting Pins. SpotBot® 2 systems are perfect complements to microarray core facilities, ideal for innovative research and diagnostics, and essential instruments for all microarray laboratories.

Click HERE to view the Standard SpoCLe Generator.

Click HERE to view the Multiple Microarray SpoCLe Generator.

Click HERE to view the Biacore SpoCLe Generator.

Click HERE to view the 96 & 384 Well Plate SpoCle Generator

Humidity Control Apparatus for SpotBot 2.

Megasonic Wash Station Upgrade!

Gal help file: http://www.spotsupport.com/downloads/GALCreatorV2.0.02HELP.pdf

SpotBot® 2 Features and Specifications

- SpotBot® 2 offers improved speed, precision and durability over SpotBot®

- 300 installations world-wide

- Axis resolution and repeatability of ±10 µm

- Arrayit International patented printing technology (U.S. 6,101,946)

- 4-pin printhead configuration (2 x 2 at 4.5 mm spacing)

- Compatible with all Stealth and 946 and Professional Micro Spotting Pins

- Capacity of 14 standard sized glass substrate slides (25 x 76 mm)

- Capacity of one 384-well microplate

- Printing routines allow 1-5 spots per sample

- 3,600 spots per sub-microarray (9 x 9 mm)

- 50,400 spots per entire substrate (18 x 63 mm)

- Printing time of 2 hrs per 384-well microplate

- >1,000 samples in 6 hours

- Compatible with Windows XP, 2000, and NT 4.0

- Power requirements: Standard 120 or 220 volt outlets

- Ease-of-operation via new version 3 Graphical User Interface (GUI)

- Size (H x L x W): 22 cm (8.7 in) x 30 cm (11.8 in) x 30 cm (11.8 in)

- Weight: 6.4 Kg (14 lbs) including vacuum and peristaltic pumps

Unique Features of the SpotBot® 2

- Only truly portable microarrayer available at 1.0 cubic foot in size.

- Installation time of less than 60 minutes.

- Arrives pre-calibrated from our California laboratories.

- Only system that uses micro-robotics for motion control.

- “Zero” thermal emission, ultra-low energy consumption, and quiet operation.

- Uses a forced air stream for pin drying, providing "zero" sample carry-over.

- Super fast humidity control of 5% per minute and ±1 % at steady state.

- Ultra-low wash buffer consumption of <1.0 liter per 8 hours of operation.

- Ultra-low air turbulence minimizes sample evaporation during printing.

- Ultra-low vibration improves printing quality and eliminates disruption of analytical balances, microscopes, scanners and other sensitive equipment.

- Private label and OEM packages available to volume customers.

- Only personal microarrayer in the world.

SpotBot® 2 Components

- 1 SpotBot® 2 Personal Microarrayer

- 1 Professional Style 4-Pin Printhead

- 4 946MP4 Pins (or customer choice of any pin tip size)

- 1 Calibration Pin (to check factory or customer calibration)

- 1 Substrate Locator L-Bracket

- 4 Anti-Vibration Pads (place one under each instrument foot)

- 1 Air Compressor to power the Dry Station

- 1 Peristaltic Pump to power the Wash Station

- Complete Tubing Set (installed at factory)

- 1 Wash Buffer Reservoir (1 liter capacity)

- 1 Waste Buffer Container (1 liter capacity)

- 1 Liter of 1X SpotBot® 2 Wash Buffer

- 1 x 50 ml of 2X Micro Spotting Solution Plus

- 1 x 25 SuperAmine Microarray Substrates (for test printing)

- 1 x 384-Well Microplate

- 1 Voltage Converter (110-220 volt)

- 1 COM Port Data Transfer Cable

- 1 SpotSuite Software Installation CD

- 1 Calibration CD (must be installed by the customer prior to operation!)

- Full One-Year Parts and Warranty Package (extra charge)

- (Option) SpotBot® 2 Complete Desktop Manufacturing System

- (Option) SpotBot® 2 Protein Edition with Cooled Platen

- (Option) Humidity Control Apparatus

- (Option) Megasonic Wash Station

Important Technical Note

SpotBot® 2 Personal Microarrayers are calibrated in our laboratories in California to ensure proper Z-axis height over the substrates and platen, and correct pin placement in the wash and dry station, and 384-well microplate. These calibration files are provided on a compact disc in addition to the SpotSuite 3 installer CD. Calibration files are unique to your system and must be installed prior to operating your SpotBot® 2 system!

Figure 1. SpotBot® 2 printed circuit board. Shown is the printed circuit board and operation lights of the SpotBot® 2. Operation is computer-controlled and fully automated. The printhead shown in this photograph contains a calibration pin in the first of 4 pin apertures.

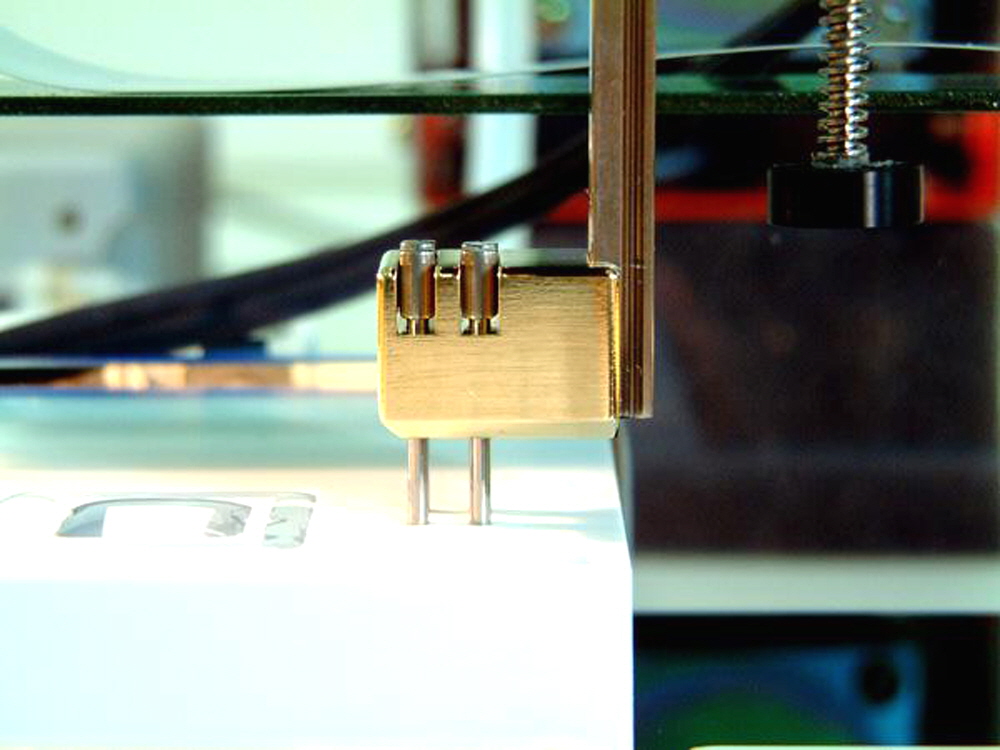

Figure 2. Shown is the wash and dry station of the SpotBot® 2, with the wash port (left) and the drying port (right). The printhead containing 4 Stealth Pins is fully inserted into the dry station in this photograph such that the collars rise above the top surface of the printhead by about 1.0 mm. Customers can also use 946 Pins with extended collars for ease-of-handling and greater printing precision. A forced air stream generated by the SpotBot® 2 Air Compressor dries each pin independently, essentially eliminating sample carry-over. Cross-contamination can be further reduced further with the Megasonic Wash Station option, a highly recommended option for exacting users and protein microarray applications.

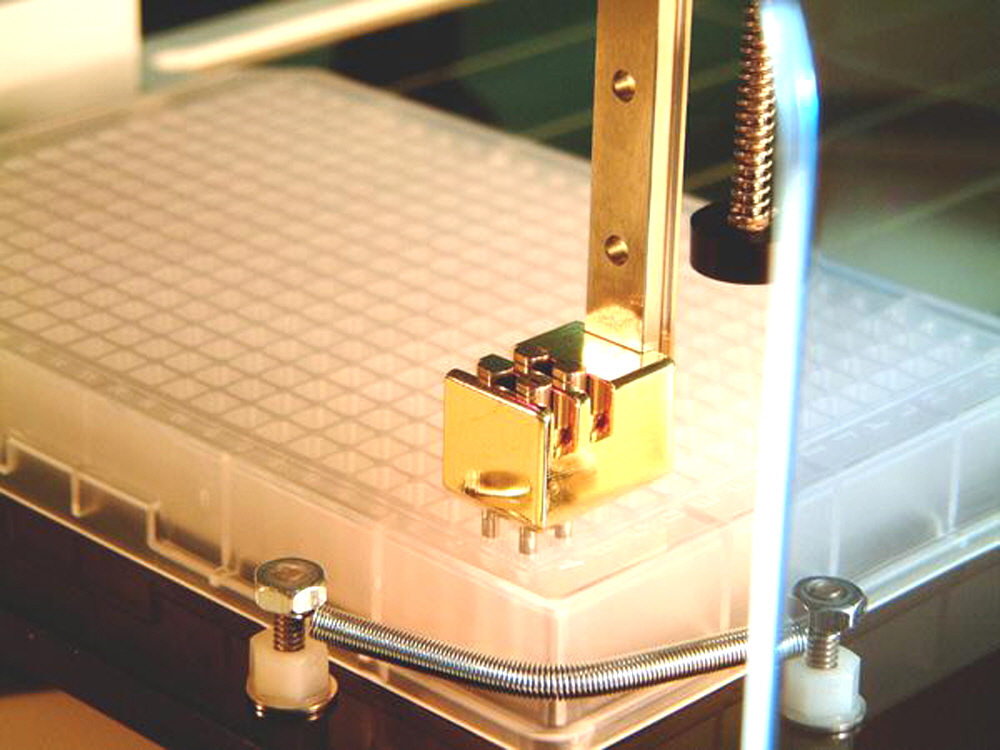

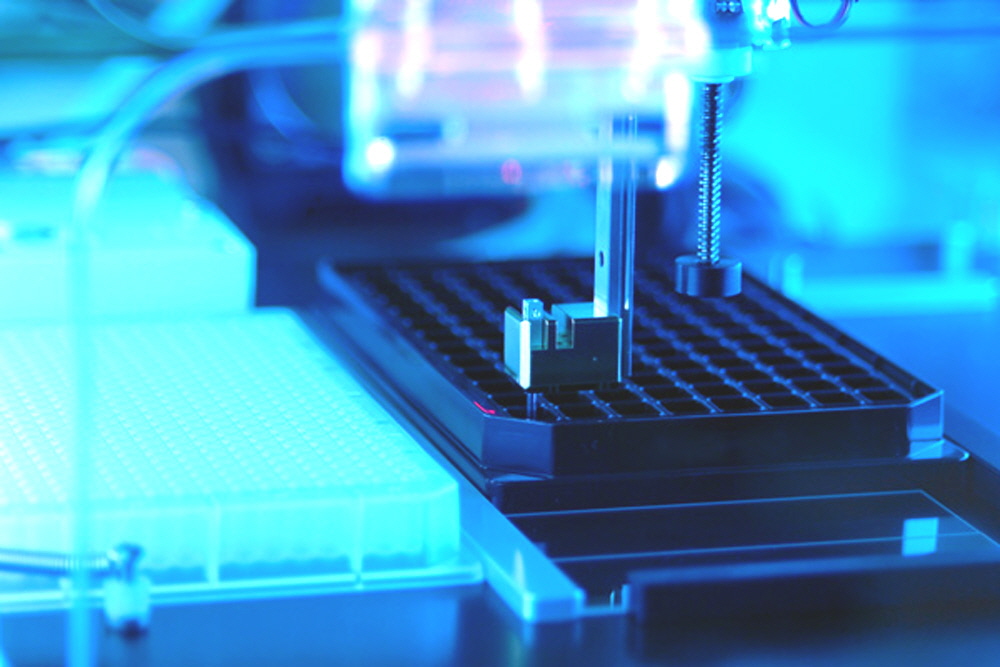

Figure 3. Shown is the SpotBot® 2 in the sample loading position. After the wash/dry step, the 4-pin Printhead moves over the first loading position in the 384-well microplate, lowers to the bottom of the plate, and pauses for 3 seconds allowing the samples load into the pin tips by capillary action. Each pin loads 0.2 µl of sample using the SMP4 or 946MP4 pin design. The recommended sample volume is 5-10 µl per well in a 384-well microplate. The SpotBot® 2 will print an entire 384-well plate across 14 substrates in less than 2 hours.

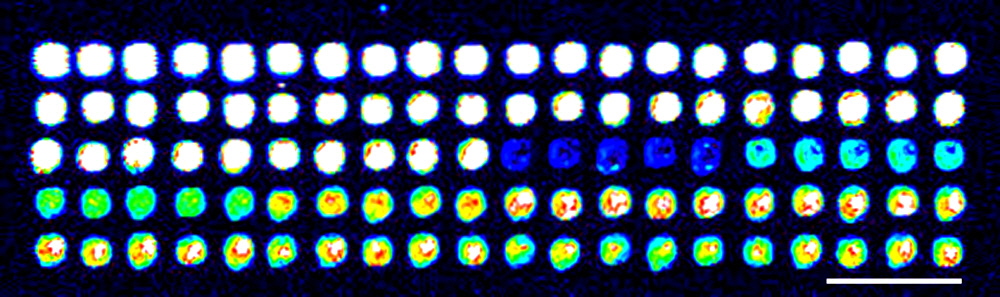

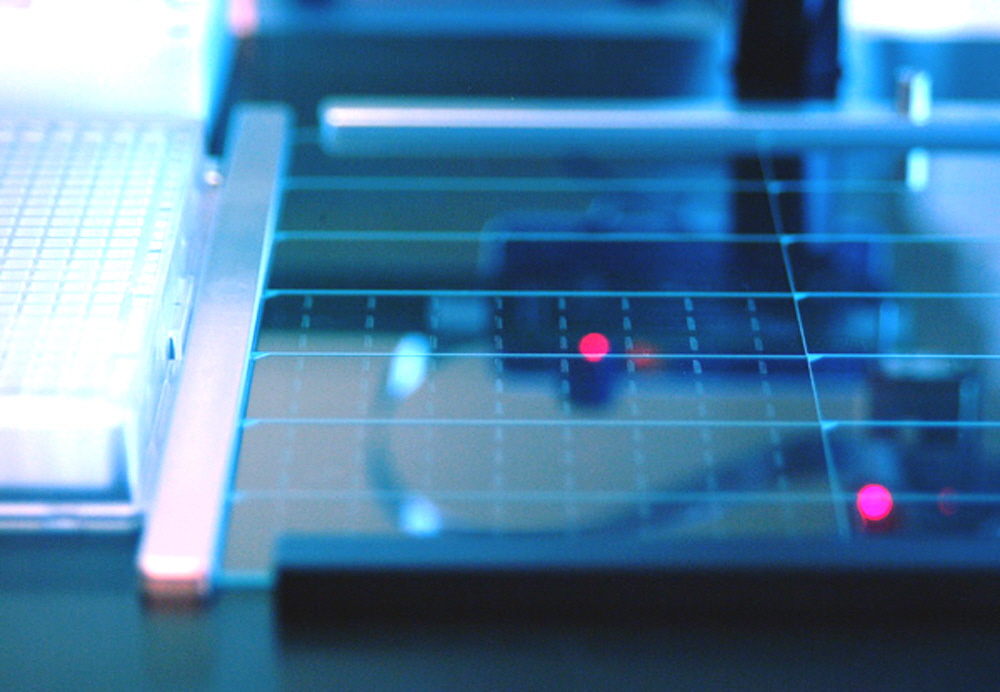

Figure 4. Microarray printed with dilutions of ArrayIt® Green540 and Red640 fluorescent dyes using the SpotBot® 2 equipped with four 946MP4 Pins and a 946PH4 Printhead. All samples were printed in quintuplicate at 200-µm center-to-center spacing on SuperAmine Substrates. The uniformity of the rows and columns of printed spots reveals the excellent printing performance of the SpotBot® 2. The space bar denotes 500 µm in the image.

Figure 5. Multiple microarrays per substrate printed with a SpotBot® 2 Personal Microarray Robot. Shown is a photograph of the SpotBot® 2 platen containing SuperAmine Microarray Substrates printed with a SpotBot® 2 Personal Microarrayer running 946MP4 Pins printing at 175 µm spacing. A total of 24 microarrays per substrate were printed using the Multiple Microarray Format SpoCLe Generator version 1.1.02, which can be downloaded at http://www.spotsupport.com.

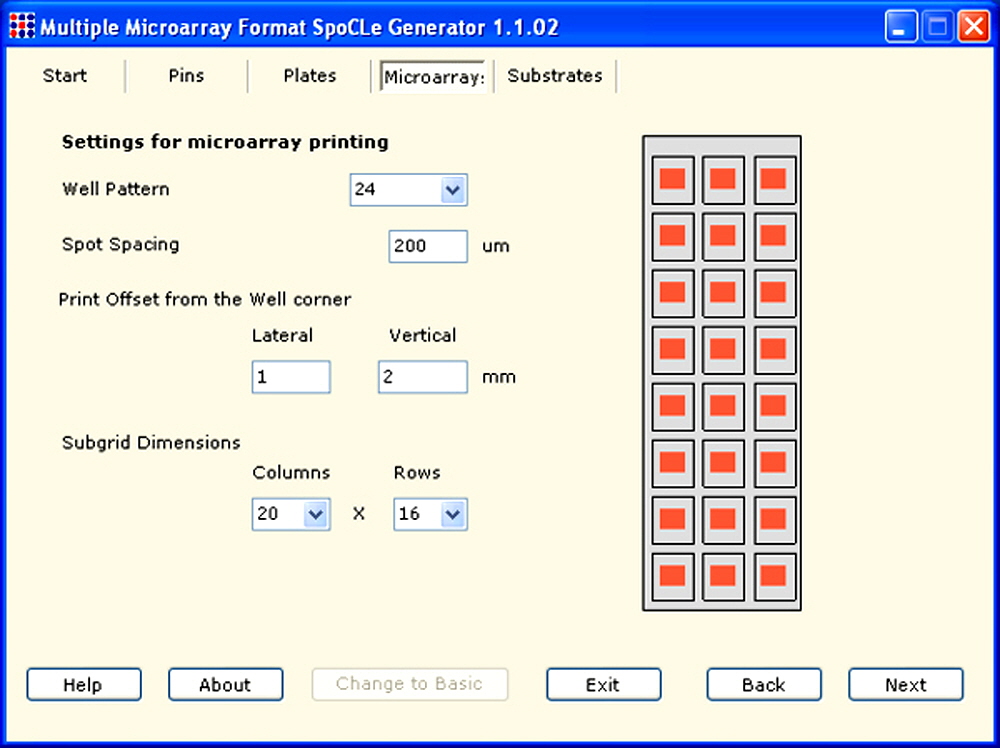

Figure 6. Multiple Microarray Format SpoCLe Generator version 1.1.02 allows the printing of multiple microarrays per substrate with SpotBot 2 Personal Microarrayers (see Fig. 5). Shown is a screenshot of the software interface. The user selects the number of microarrays or “well pattern”, spot spacing in microns, print offsets in millimeters, and subgrid dimensions as columns and rows. The software then generates a graphic showing how the printed microarrays (orange icons) will appear on the substrates. The Multiple Microarray Format SpoCLe Generator version 1.1.02 can be downloaded at

www.spotsupport.com.

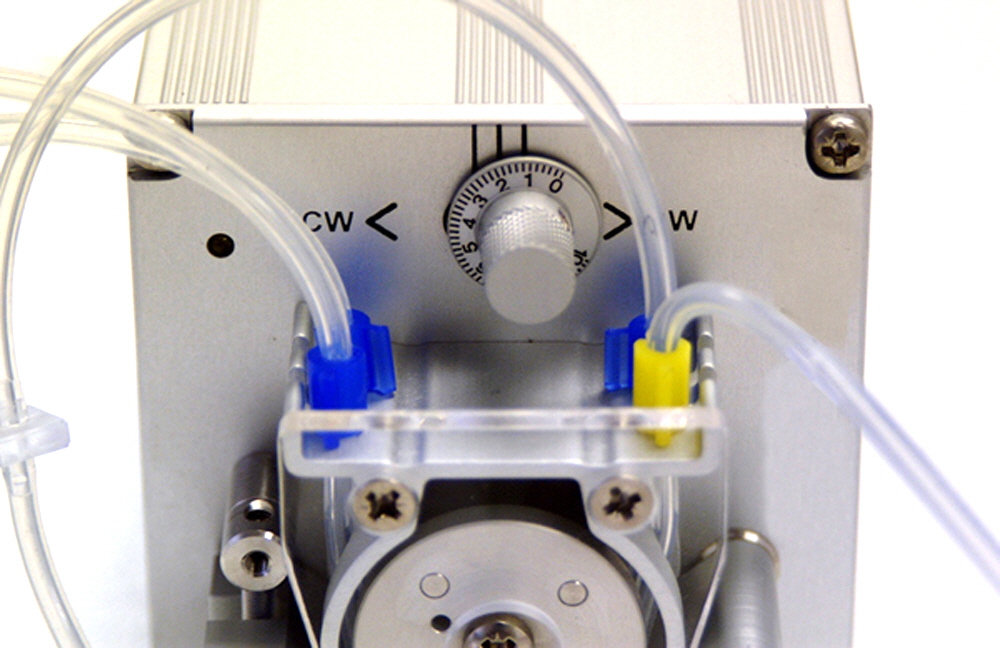

Figure 7. Shown is a photograph of the Peristaltic Pump used on SpotBot®2 Personal Microarrayers. Tubing colors should be configured as shown. The speed dial should be set to the right (CW, clockwise setting) for correct buffer flow into the Wash Station. Pumps are either 12 rpm or 100 rpm as designated on the back of the instrument under “speed”. A proper buffer flow rate of 1.0 ml/min into the SpotBot®2 Wash Station is achieved using dial setting 8 (12 rpm pump) or dial setting 1 (100 rpm pump, shown here). Tubing connections (not shown) should be green-green, blue-blue, yellow-yellow, and white-white as designated on the tubing ends and hardware: green-green = Peristaltic Pump intake to Wash Buffer Reservoir; blue-blue = Peristaltic Pump intake to Wash Station outlet; white-white = Peristaltic Pump outlet to Wash Station intake; yellow-yellow = Peristaltic Pump outlet to Wash Waste Container.

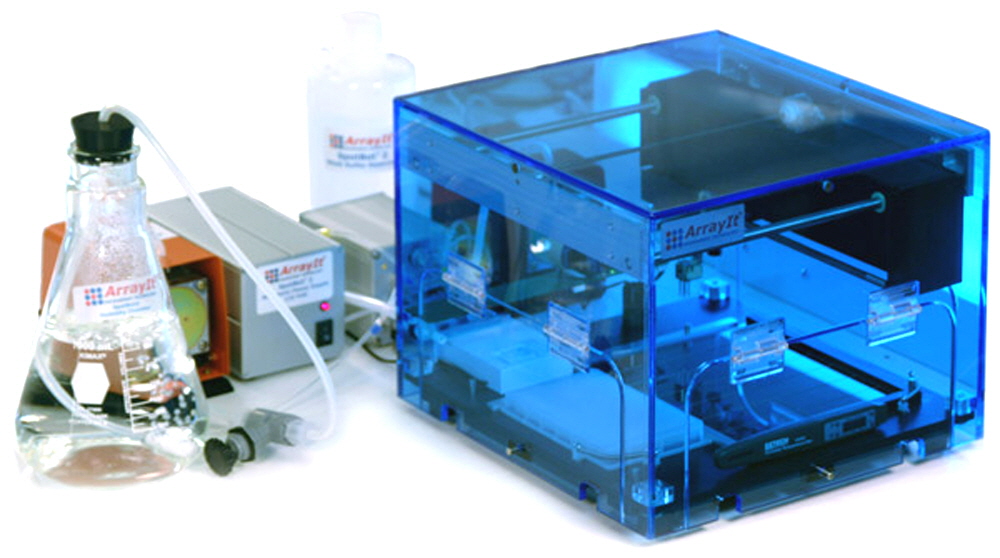

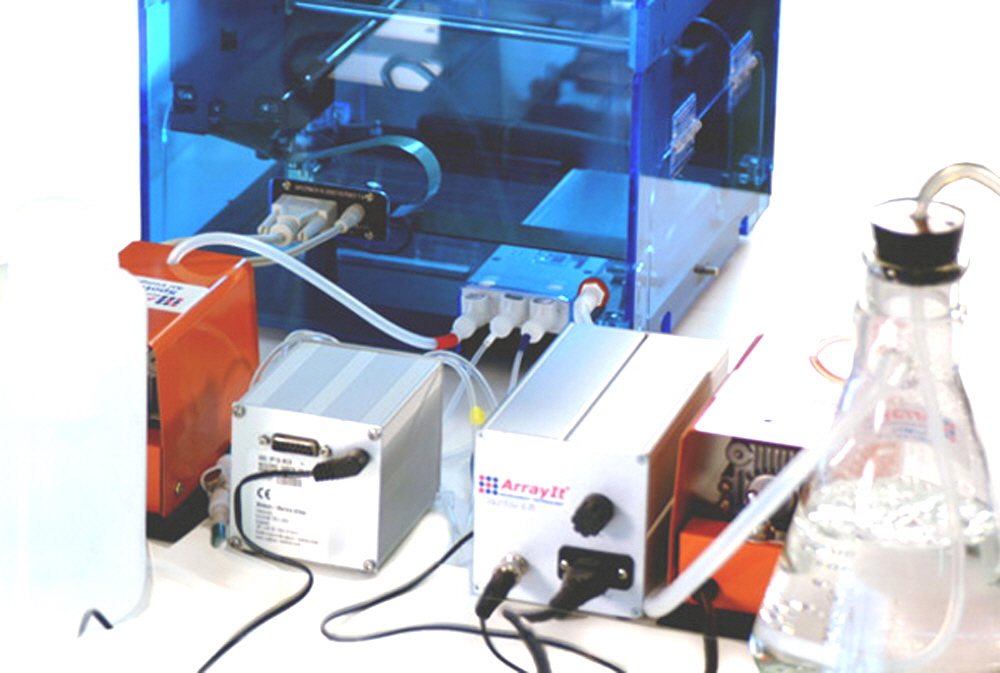

Figure 8. Shown is a photograph of the SpotBot®2 Personal Microarrayer including the accessories. The translucent wash buffer reservoir, orange air compressor for the dry station, silver peristaltic pump for the wash station, silver megasonic power supply and humidification system including the orange air compressor, humidification reservoir and gray valve are shown correctly configured behind the instrument. The modular and compact accessories improve system utility and performance and simplify maintenance and repair. Inside the instrument, the microplate, L-bracket and temperature/humidity pen are visible.

Figure 9. Shown is a photograph of the SpotBot®2 Personal Microarrayer including the accessories. The translucent wash buffer reservoir, orange air compressor for the dry station, silver peristaltic pump for the wash station, silver megasonic power supply and humidification system including the orange air compressor and humidification reservoir are shown correctly configured behind the instrument. The COM cable, power supply, dry station fitting (red), wash buffer fitting (white), waste buffer outtake (blue), and humidification tubing are shown correctly attached to the back of the instrument. The modular and compact accessories design improves system utility and performance and simplifies maintenance and repair.

Figure 10. SpotBot®2 Microplate Printing. SpotBot®2 Personal Microarrayers enable microarray printing into 96-well microplates (shown) and 384-well microplates, as well as onto microplate-sized glass substrates using the standard SpotBot®2 components and Well Plate Printing Spocle Generator v2.0.2 software running on SpotApp v3.5.7. Microplate printing software is downloadable on the SpotSupport web site. Microplate printing requires the Microplate L-Bracket Locator (Cat. MLS) to hold the microplate in position during printing, and utilizes two pre-print substrates as shown here. System calibration is required prior to printing. Please do not attempt microplate printing prior to system calibration.

Scientific Publications

Click on the links to review recent scientific publications featuring ArrayIt® brand SpotBot® Personal Microarrayers.

Recommended Equipment and Reagents

NanoPrint™ 2 Enterprise Level Microarrayers

Microarray Contact Printing Technology

InnoScan® Microarray Laser Scanners

SpotLight™ Personal Microarray Scanners

SpotWare™ Colorimetric Microarray Scanners

Microarray High-Speed Centrifuge

High-Throughput Wash Stations

Microarray Hybridization Cassettes

Super Microarray Substrates

Microarray Purification Kits

Microarray Hybridization and Blocking Buffers

Microarray Print Buffers

Microarray Wash Buffers

SpotBot® 2 Wash Buffer