Pin Cleaning

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Microarray pin cleaning sonicators sonication ultrasonic bench top pin racks detergent reagents tools 110 220 volt life sciences research

Instruments - Microarray Processing - Pin Cleaning Kits for Ultrasonic Cleaning of Microarray Printing Pins and Printheads

ArrayIt® Pin & Printhead Cleaning Kits provide complete ultrasonic solutions to pin and printhead cleaning and maintenance. Based on proprietary surface chemistry and cleaning technology, these kits are highly recommended for all microarray printing pins and printheads including Arrayit Professional, 946, Stealth and ChipMaker™ customers.

Table of Contents

- Introduction

- Quality Control

- Technical Assistance

- Product Description

- Protocols

- Ordering Information

- Warranty

Introduction

Congratulations on taking a big step towards improving your microarray research. This booklet describes how to use the equipment, tools, and reagents in Arrayit Pin and Printhead Cleaning Kits.

Quality Control

Arrayit assures the performance of this product. The finest scientific research went into the development of this kit.

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com (under the subject heading, please type ArrayIt® technical assistance). By email: arrayit@arrayit.com, Monday–Friday PST 8:30am - 5:30 PM. Please remember that we want to hear about your successes!

Product Description

The ArrayIt® Pin and Printhead Cleaning Kit includes a sonicator and a complete set of tools and reagents required for cleaning and maintenance of Stealth™ and ChipMaker™ Micro Spotting Pins and Printheads. The kit is available in two versions, with or without the ultrasonic bath, to meet the needs and budgets of any laboratory. The Pin and Printhead Cleaning Kits contain the following components:

- 1 Ultrasonic Bath [I.D. 5.5" (14 cm) x 5" (13 cm) x 4 " (10 cm), LxWxH]

- 1 Floatable Pin Cleaning Rack [O.D. 5" (13 cm) x 4" (10 cm) x 3.5" (9 cm), LxWxH]

- 1 Pin Drying Lid

- 500 ml of ArrayIt® Micro Cleaning Solution

- 250 grams of Pin Tip Cleaning Reagent

- 250 grams of Printhead Cleaning Reagent

- 10 Cleanroom Wipes

- 1 Pin Tip Brush (fine)

- 1 Printhead Cleaning Brush (rectangular)

- 6 Printhead Cleaning Brushes (cylindrical)

Protocols

Protocol 1. Light Pin Cleaning (Short Protocol)

This protocol is designed for mild cleaning of Stealth™ and ChipMaker™ Micro Spotting Pins in between print runs, to remove minor surface contaminants such as salts and organic films that may diminish printing performance.

1. Fill Ultrasonic Bath with 1 liter of distilled H2O.

2. Place Pins in Floatable Pin Cleaning Rack.

3. Place Rack with Pins in Ultrasonic Bath.

4. Sonicate for 5 min.

5. Remove Rack and dry Pins.

6. Place clean Pins in Printhead and resume printing.

Protocol 1. Light Pin Cleaning (Complete Protocol)

This protocol is designed for mild cleaning of Stealth™ and ChipMaker™ Micro Spotting Pins in between print runs an` on a daily or weekly basis, to remove minor surface contaminants such as salts and organic films that may diminish printing performance.

1. Fill Ultrasonic Bath with 1 liter of distilled H2O. Before use, make sure to rinse the Ultrasonic Bath exhaustively with tap water and then distilled water to remove any residual cleaning solution that may be present in the bath from a previous cleaning session. It is essential to remove all traces of detergent and other reagents prior to beginning the Light Pin Cleaning protocol. Failure to use pure distilled H2O for the cleaning step may decrease printing efficiency.

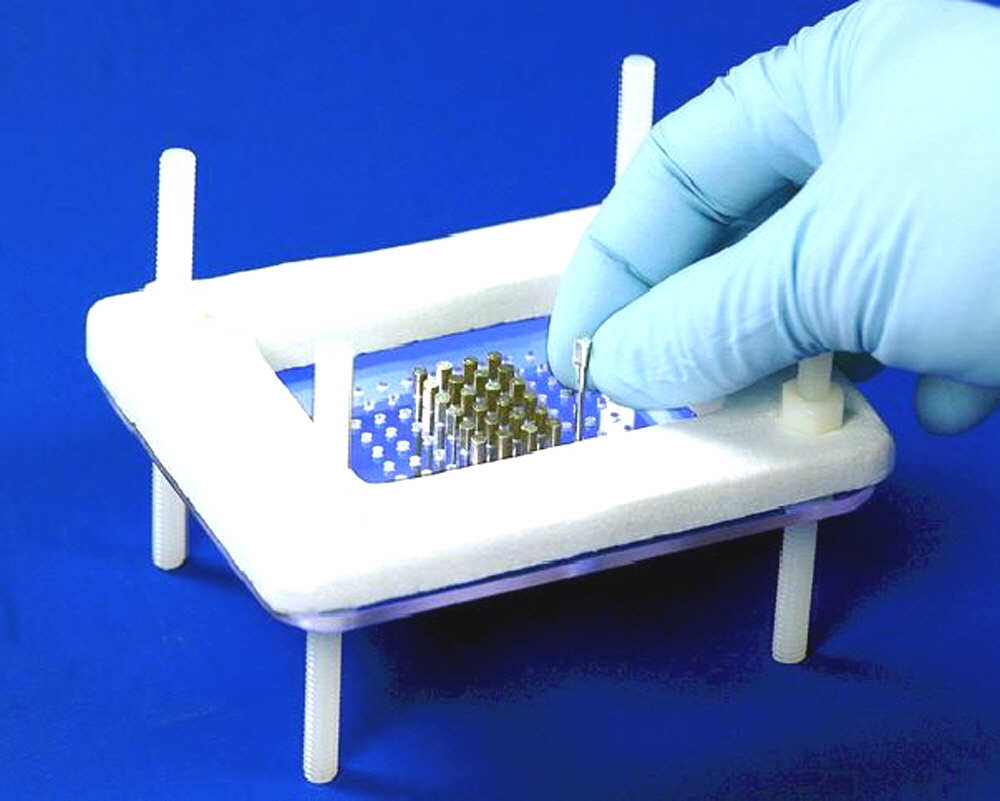

2. Place Pins in Floatable Pin Cleaning Rack. Place the Rack on a benchtop or other solid surface and carefully insert the Pins straight into the holes in the Rack, such that the underside of the Pin collar comes to rest against the top surface of the Pin Rack (Fig. 1). The Pin Rack will accommodate both Stealth™ and ChipMaker™ Micro Spotting Pins. Bumping the Pin tips against the top surface of the Rack, or inserting the Pins into the holes of the Rack at an angle, may bend or damage the Pins. Please use caution at all times when handling Micro Spotting Pins. Make certain to wear nitrile gloves at all times when handling Pins and Printheads!!

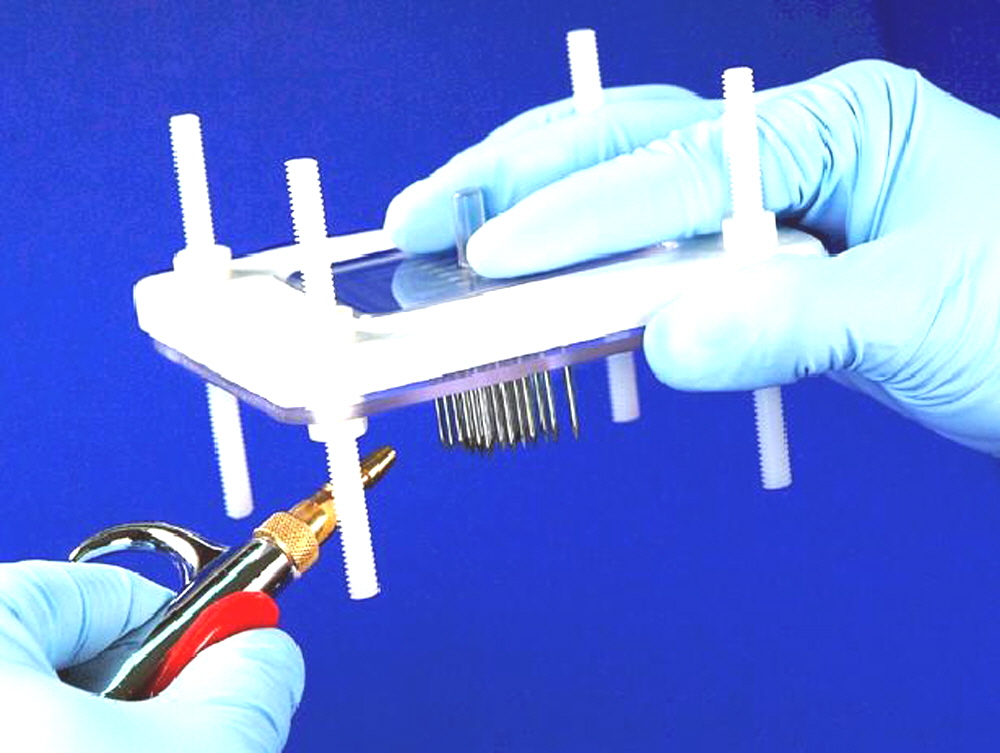

3. Place Rack with Pins in Ultrasonic Bath. Once each Pin is inserted into a separate hole of the Floatable Pin Cleaning Rack, place the Rack right side up into the Ultrasonic bath in a careful manner. The Rack loaded with Pins will float in the one-liter volume of distilled H2O (Fig. 2).

4. Sonicate for 5 min. Make sure the Ultrasonic Bath is plugged into an electrical outlet, and initiate the cleaning process by turning the Ultrasonic Bath timer dial clockwise to the 5 min setting. The Bath will initiate ultrasonic cleaning automatically. The sonic waves will remove deposits and other contaminants from the Pin tips. To avoid damaging the Ultrasonic Bath, donot operate the bath with cleaning volumes less than one liter, and make sure nothing is resting against the bottom of the tank during the sonication process.

5. Remove Pins and dry. Once the 5 min cleaning process has concluded, remove the Floatable Pin Cleaning Rack from the sonic tank and place it right side up on a flat surface such as a benchtop. Allow the Rack to drip dry for 1 min to drain away excess distilled H2O, then blot the top and outer surfaces of the Rack and Pins carefully with a Cleanroom Wipe, making certain not to touch the Pin tips. Pins can be dried to completion using a forced air stream (Fig. 3). To dry Pins using forced air, cover the tops of the Pins with the Pin Drying Lid and apply a forced air stream to the Rack and Pins horizontally as shown (Fig. 3). Make sure to use a horizontal source of particle and oil-free forced air. Do not use canisters of pressurized propellant, as such sources may contain organic compounds that will contaminate the Pins with oily residues and reduce printing performance. Make certain not to touch the Pin tips with the forced air nozzle at any time during dying, as this may damage or bend the Pin tips. Drying will be complete in 30-60 sec. An alternative method of Pin drying involves the use of a Cleanroom Wipe. Hold a Micro Spotting Pin by the collar and dry the Pin by passing the Cleanroom Wipe down the Pin shaft and off the tip of the Pin in a gentle manner. This process will dry the Pin and remove distilled water from the Pin channel. Make certain to wipe the Pin gently and do not run the Cleanroom Wipe in a perpendicular manner across the Pin tip. Wipe Pins carefully to avoid bending or damaging the tips.

6. Place Clean Pins in Printhead and resume Printing. Once the Micro Spotting Pins rae clean and dry Place them into a Printhead carefully and resume the printing process. Insert Pins straight intpo the Printhead and make sure that the robot is calibrated and functioning properly before resuming printing

Fig. 1. Insert Pins in Floatable Pin Cleaning Rack. Shown is the method for loading Arrayit Micro Spotting Pins into the cleaning Rack. Pins should be inserted straight into the holes, such that the collars come to rest against the top of the Rack.

Fig. 2. Place Floatable Pin Cleaning Rack with Pins into the Ultrasonic bath. The Ultrasonic Bath should contain one liter of distilled H2O (Light Pin Cleaning), or one liter of 5% Micro Cleaning Solution (Routine and Intensive Pin Cleaning). The Rack will float in the one-liter volume of liquid. Cleaning in the Ultrasonic Bath is initiated by turning the timer dial clockwise to the 5 min setting (Light and Routine Pin Cleaning) or to the 15 min setting (Intensive Pin Cleaning).

Fig. 3. Dry Pins in Floatable Pin Cleaning Rack using a stream of forced air. Arrayit Micro Spotting Pins may be dried after sonic cleaning, using a particle- and oil-free source of forced air. Make sure to cover the tops of the Pins with the Pin Drying Lid as shown and press down firmly with one hand. The tip of the forced air source (left) should not come into direct contact with the Pin tips at any time during the drying procedure. Use a horizontal air stream for Pin drying.

Protocol 2. Routine Pin Cleaning (Short Protocol)

This protocol is intended for routine cleaning of Stealth™ and ChipMaker™ Micro Spotting Pins in between print runs or after Pin storage, to remove surface contaminants such as salts and organic films that may diminish printing performance.

1. Fill Ultrasonic Bath with 1 liter of 5% Micro Cleaning Solution.

2. Place Pins in Floatable Pin Cleaning Rack.

3. Place Rack with Pins in Ultrasonic Bath.

4. Sonicate for 5 min.

5. Rinse bath and Rack with Pins exhaustively with tap water.

6. Sonicate for 5 min in distilled H2O.

7. Remove Pins and dry.

8. Place clean Pins in Printhead and resume printing.

Protocol 2. Routine Pin Cleaning (Complete Protocol)

This protocol is intended for routine cleaning of Stealth™ and ChipMaker™ Micro Spotting Pins in between print runs or after Pin storage, to remove surface contaminants such as salts and organic films that may diminish printing performance.

1. Fill Ultrasonic Bath with 1 liter of 5% Micro Cleaning Solution. One liter (1,000 ml) of 5% Micro Cleaning Solution is prepared by adding 50 ml of Micro Cleaning Solution concentrate to 950 ml distilled H2O, and mixing thoroughly. Make sure to rinse the Ultrasonic Bath exhaustively with tap water and then distilled water before use, to remove residual cleaning solution or other reagents that may be present in the bath from a previous cleaning.

2. Place Pins in Floatable Pin Cleaning Rack. Place the Rack on a benchtop or other solid surface and carefully insert the Pins straight into the holes in the Rack, such that the underside of the Pin collar comes to rest against the top surface of the Pin Rack (Fig. 1). The Pin Rack will accommodate both Stealth™ and ChipMaker™ Micro Spotting Pins. Bumping the Pin tips against the top surface of the Rack, or inserting the Pins into the holes of the Rack at an angle, may bend or damage the Pins. Please use caution at all times when handling Micro Spotting Pins. Make certain to wear nitrile gloves at all times when handling Pins and Printheads!!

3. Place Pins and Rack in Ultrasonic Bath. Once each Pin is inserted into a separate hole of the Floatable Pin Cleaning Rack, place the Rack right side up into the Ultrasonic bath in a careful manner. The Pin Rack will float in the one-liter volume of 5% Micro Cleaning Solution (Fig. 2).

4. Sonicate for 5 min. Make sure the Ultrasonic Bath is plugged into to an electrical outlet and initiate the cleaning process by turning the timer dial clockwise to the 5 min setting. The Ultrasonic Bath will initiate ultrasonic cleaning automatically. To avoid damaging the Ultrasonic Bath, donot operate the bath with cleaning volumes less than one liter, and make sure nothing is resting against the bottom of the tank.

5. Rinse bath and Rack with Pins exhaustively with tap water. After the 5 min cleaning step in 5% Micro Cleaning Solution, remove the Floatable Pin Cleaning Rack containing the Micro Spotting Pins from the Ultrasonic bath and place it on a flat surface such as the bottom of a laboratory sink. Rinse the Rack containing the Micro Spotting Pins exhaustively with warm tap water for 1-2 min to remove all of the Micro Cleaning Solution. Once the Rack and Pins have been rinsed, unplug the Ultrasonic Bath from the electrical outlet (essential!) and rinse it for 1-2 min with warm tap water. Exhaustive rinsing is absolutely essential! Do not proceed to the next step until you are certain that all of the Micro Cleaning Solution has been removed from the Rack, Pins and Ultrasonic Bath.

6. Sonicate for 5 min in distilled H2O. Re-fill the Ultrasonic Bath with 1 liter (1,000 ml) of distilled H2O and initiate the cleaning process by turning the timer dial clockwise to the 5 min setting. The Ultrasonic Bath will initiate ultrasonic cleaning automatically. This step is essential for removing trace amounts of Micro Cleaning Solution from the Pins. Failure to perform this step will reduce printing efficiency.

7. Remove Pins and dry. Once the 5 min distilled H2O cleaning process has concluded, remove the Floatable Pin Cleaning Rack with Pins from the sonic tank and place it right side up on a flat surface such as a bench top. Allow the Rack to drip dry for 1 min to remove excess distilled H2O and blot the top and outer surfaces of the Rack and Pins carefully, making certain not to touch the Pin tips. Pins can be dried to completion by the use of forced air (Fig. 3). To dry Pins using forced air, cover the tops of the Pins with the Pin Drying Lid and apply a forced air stream to the Rack and Pins in a horizontal manner (Fig. 3). Make sure to use a source of particle and oil-free forced air. Do not use canisters of pressurized propellant, as these sources of air may contain organic compounds that can leave a residue on the pin tips and reduce printing performance. Make certain not to touch the Pin tips with the forced air nozzle at any time during dying, as this may damage or bend the Pin tips. Drying will be complete in 30-60 sec. An alternative method of Pin drying involves the use of a Cleanroom Wipe. Hold a Micro Spotting Pin by the collar in one hand, and dry the Pin by running the Cleanroom Wipe down the Pin shaft and off the tip of the Pin in a gentle manner using the other hand. Hand drying the Pin will remove distilled water from the Pin shaft and channel. Make certain to wipe the Pin gently and do not run the Cleanroom Wipe in a perpendicular manner across the Pin tip, to avoid bending or damaging the tips.

8. Place clean Pins in Printhead and resume printing. Once the Micro Spotting Pins are clean and dry, place them into a Printhead carefully, and resume the printing process. Insert Pins straight into the Printhead and make sure the robot is calibrated and functioning properly before resuming printing.

Protocol 3. Intensive Pin Cleaning (Short Protocol)

This protocol is intended for intensive cleaning of Stealth™ and ChipMaker™ Micro Spotting Pins, in cases where Pins need to have the surface tension properties of the tips restored or have accumulated minor corrosion due to intensive use, improper storage, or misuse. This protocol will remove minor corrosion, deposits and other contaminants that diminish printing performance.

1. Clean Pin tips by topical application of Pin Tip Cleaning Solution.

2. Fill Ultrasonic Bath with 1 liter of steam distilled water.

3. Place Pins in Floatable Pin Cleaning Rack.

4. Place Rack with Pins in Ultrasonic Bath.

6. Sonicate for 5 min in distilled H2O.

7. Remove Pins and dry.

8. Place clean Pins in Printhead and resume printing

Protocol 3. Intensive Pin Cleaning (Complete Protocol)

This protocol is intended for intensive cleaning of 946, Stealth™ and ChipMaker™ Micro Spotting Pins in cases where Pins have lost surface tension properties and are spotting intermittenly or have accumulated minor corrosion due to intensive use, improper storage, or misuse. This protocol will remove minor corrosion, deposits and other contaminants that diminish printing performance.

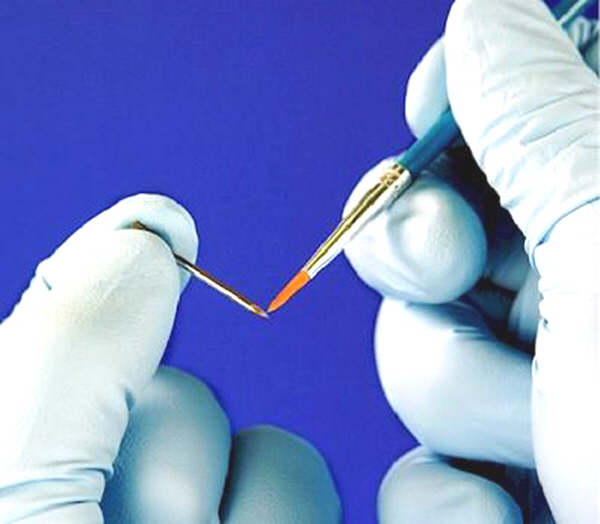

1. Clean Pin tips by topical application of Pin Tip Cleaning Solution. Prepare 50 ml of hot (65°C) Pin Tip Cleaning Solution. To a 250 ml beaker, add 50 ml distilled H2O and heat it to 65°C in a microwave oven or on a hot plate. Water temperature can be measured using a standard mercury thermometer. Add 15 grams Pin Tip Cleaning Reagent to the 65°C water and mix thoroughly until the solid reagent dissolves completely. Apply the cleaning solution to the Pin tips by dipping the Pin Tip Brush (fine) into the Pin Tip Cleaning Solution, and brush the surface of each Pin tip until the oxidation layer has been removed (Fig. 4). Pin tips require 10-20 applications over a 2 min period to remove the oxidation layer. Tips can be inspected under a dissection microscope for enhanced viewing. Pin Tip Cleaning Solution is corrosive and toxic. Make sure to wear gloves and safety glasses at all times when using this solution. Pin Tip Cleaning Solution removes metal oxides that can form on the tips of Pins through improper storage, misuse or intensive printing in humid environments. Removing this oxidation layer will restore the “shiny” stainless steel finish required for proper Pin loading and printing movement. Soaking Pins in Pin Tip Cleaning Solution for more than a few minutes may result in permanent Pin damage. Do not do this under any circumstances! Once each Pin has been cleaned topically with Pin Tip Cleaning Solution, proceed to the next step.

2. Fill Ultrasonic Bath with 1 liter of steam distilled water. Before use, make sure to rinse the Ultrasonic Bath exhaustively with tap water and then distilled water, to remove old cleaning solution and other reagents that may be present in the bath from a previous cleaning.

3. Place Pins in Floatable Pin Cleaning Rack. Place the Rack on a solid surface such as a benchtop and insert the Pins straight into the holes in the Rack in a careful manner, until the underside of the Pin collar comes to rest against the top surface of the Pin Rack (Fig. 1). The Pin Rack will accommodate both 946, Stealth™ and ChipMaker™ Micro Spotting Pins. Dragging the Pin tips across the top surface of the Rack or inserting the Pins into the holes of the Rack at an angle, can lead to Pin damage. Please use caution at all times when handling Micro Spotting Pins. Make certain to wear nitrile gloves at all times when handling Pins and Printheads!!

4. Place Rack with Pins in Ultrasonic Bath. Once each Pin is inserted into a separate hole of the Floatable Pin Cleaning Rack, place the Rack right side up into the Ultrasonic bath in a careful manner. The Pin Rack will float in the one-liter volume of water (Fig. 2).

5. Sonicate for 5 min in distilled H2O. Re-fill the Ultrasonic Bath with 1 liter (1,000 ml) of distilled H2O and initiate the cleaning process by turning the timer dial clockwise to the 5 min setting. The Ultrasonic Bath will initiate ultrasonic cleaning automatically. This step is essential for removing trace amounts of Micro Cleaning Solution from the Pins. Failure to perform this step will reduce printing efficiency.

6. Remove Pins and dry. Once the 5 min distilled H2O cleaning process has concluded, remove the Floatable Pin Cleaning Rack with Pins from the sonic tank and place it right side up on a flat surface such as a bench top. Allow the Rack to drip dry for 1 min to remove excess distilled H2O, and blot the top and outer surfaces of the Rack and Pins carefully, making certain not to touch the Pin tips. Pins can be dried to completion by the use of forced air (Fig. 3). To dry Pins using forced air, cover the tops of the Pins with the Pin Drying Lid and apply a forced air stream to the Rack and Pins in a horizontal manner as shown (Fig. 3). Make sure to use a source of particle and oil-free forced air. Do not use canisters of pressurized propellant, as these sources of air may contain organic compounds that can leave a residue to the Pin tips and reduce printing performance. Make certain not to touch the Pin tips with the forced air nozzle at any time during dying, as this may damage or bend the Pin tips. Drying should be complete in 30-60 sec. An alternative method of Pin drying involves the use of a Cleanroom Wipe. Hold the Micro Spotting Pin by the collar and dry the Pin by running the Cleanroom Wipe down the Pin shaft and off the tip of the Pin in a gentle manner. This process will dry the Pin and remove distilled water from the Pin channel. Make certain to wipe the Pin gently and do not run the Cleanroom Wipe in a perpendicular manner across the Pin tip, to avoid bending or damaging the tips.

8. Place clean Pins in Printhead and resume printing. Once the Micro Spotting Pins are clean and dry, place them into a Printhead carefully, and resume the printing process. Insert Pins straight into the Printhead and make sure the robot is calibrated and functioning properly before resuming printing.

Fig. 4. Cleaning Pin tips with Pin Tip Cleaning Solution. Pin Tip Cleaning Solution is brushed onto the Pin tip as shown. Topical application of 10-20 brushing and dipping cycles is usually sufficient to remove the oxidation from the Pin tip.

Protocol 4. Printhead Cleaning (Short Protocol)

1. Cover your hands with nitrile gloves and your eyes with safety glasses.

2. Remove Pins from Printhead.

3. Prepare 50 ml of hot (65°C) Printhead Cleaning Solution.

4. Scrub the outer Printhead surfaces for 5 min with the rectangular Printhead brush.

5. Scrub each Pin hole (5-10 min total) with a cylindrical brush.

6. Rinse the Printhead exhaustively with distilled water.

7. Rinse the Printhead exhaustively with 100% ethanol.

8. Dry the Printhead thoroughly with a Cleanroom Wipe or forced air.

9. Re-insert Pins.

10. Resume printing.

Protocol 4. Printhead Cleaning (Complete Protocol)

1. Cover your hands with nitrile gloves and your eyes with safety glasses. Protect your hands and eyes at all times during this procedure. Printhead Cleaning Reagent and ethanol are irritants. Never touch a Printhead directly with uncovered hands, as hand oils can lead to Pin seizing and Printhead oxidation. Nitrile gloves are preferable to latex gloves, as latex gloves contain latex proteins that can transfer to Pins and Printheads and cause Pin seizing. Eye protection should be worn at all times and eyes should be shielded completely.

2. Remove Pins from Printhead. All Pins must be removed from the Printhead prior to Printhead cleaning. Do not attempt to clean a Printhead loaded with Pins, as insufficient cleaning and permanent Pin damage may result. Pins should be stored in clean and dry place. Users of Stealth Pins will find the Stealth Pin Rack extremely useful for Stealth Pin storage. Once all Pins are removed from the Printhead, use the “manual mode” of the robot to move the Printhead onto an open position on the platen to allow for easy cleaning. If not manual mode is available, move the Printhead towards the front of the robot. Make sure to cover the arrayer platen with an absorbent bench cloth to prevent splashing the robot with cleaning solution. A rectangular collection tray (e.g Pyrex® dish) should be placed directly beneath the Printhead to collect the solution that drips off the Printhead during cleaning. Alternatively, the Printhead may be removed from the robot for easy cleaning. In this case, place the Printhead in a rectangular collection tray on the bench top. Make sure to cover the bench surface with an absorbent bench cloth.

3. Prepare 50 ml of hot (65°C) Printhead Cleaning Solution. To a 250 ml beaker, add 50 ml distilled water and heat it to 65°C in a microwave oven or on a hot plate. Water temperature can be measured using a standard mercury thermometer. Add 15 grams Printhead Cleaning Reagent to the 65°C water and mix thoroughly until the solid reagent dissolves completely. Printhead Cleaning Solution is corrosive and toxic. Make sure to wear gloves and safety glasses at all times when using this solution. Printhead Cleaning Solution removes oxides of copper and zinc that accumulated on the Printhead over time. Copper and zinc oxides create friction in the Pin holes, causing Pins to seize or “stick” during printing. The copper and zinc oxide layer has a thickness of only a few atoms, however, and removing this layer will not impair the function of the Printhead, but rather simply returns the “shiny finish” required for frictionless Pin movement. Soaking Printheads in Printhead Cleaning Solution for more than a few minutes may result in permanent Printhead damage. Do not do this under any circumstances!!

4. Scrub the outer Printhead surfaces for 5 min with the rectangular Printhead brush. Dip the rectangular Printhead brush into the 65°C Printhead Cleaning Solution and scrub the Printhead vigorously. Make sure to scrub all of the exterior surfaces of the Printhead, including the Pin channels and the bottom of the Printhead. Repeat the dipping and scrubbing cycles every 20-30 seconds for 5 min until the Printhead is cleaned thoroughly. Make sure to wear gloves and eye protection at all times during this process, as cleaning solution may “spray” during scrubbing.

5. Scrub each Pin hole (5-10 min total) with a fine cylindrical brush. Once the outer surfaces of the Printhead have been scrubbed thoroughly with the rectangular brush, use one of the cylindrical brushes to clean each Pin hole. Printheads contain 32, 48 or 72 Pin holes depending on the model. ChipMaker™ Printheads contain two guiding surfaces and both upper and lower Pin holes must be cleaned. Pin holes are cleaned by dipping the cylindrical brush into Printhead Cleaning Solution, inserting the brush into the Pin hole, and moving the brush up and down to remove the copper and zinc oxide layer. Make certain to insert the cylindrical brush into each Pin hole gently and in a perpendicular manner, to avoid scoring the Pin holes with the metal core of the Printhead brush. Repeat the dipping and scrubbing cycles every 20-30 seconds for 5-10 min until the Printhead is cleaned thoroughly. Make sure to wear gloves and eye protection at all times during this process, as cleaning solution may splash during scrubbing.

6. Rinse the Printhead exhaustively with distilled water. Once the outer and inner Printhead surfaces have been cleaned thoroughly (~15 min), rinse the Printhead exhaustively with distilled water at room temperature. The rinsing process will remove the Printhead Cleaning Solution. Use a total of 1 liter of distilled water in 5-10 separate rinses in a laboratory “squirt bottle” to make sure that all of the cleaning solution has been removed. This step is absolutely critical. Failure to remove all of the Printhead Cleaning Solution will impair printing by causing Pin seizing and other difficulties!

7. Rinse the Printhead exhaustively with 100% ethanol. Once the Printhead has been rinsed exhaustively with distilled water, rinse it exhaustively with 100% ethanol at room temperature to remove the rinse water. Use a total of 1 liter of 100% ethanol in a laboratory “squirt bottle” in 5-10 separate rinses to make sure that all of the distilled water has been removed. This step is absolutely critical. Failure to remove all of the distilled will impair printing by causing Pin ceasing and oxidation!

8. Dry the Printhead thoroughly with a Cleanroom Wipe or forced air. Once the Printhead has been cleaned and rinsed thoroughly, it must be dried completely before the Pins can be re-inserted. Allow the Printhead to drip dry for 5 min to remove the majority of the ethanol. After 5 min, the remaining ethanol can be removed by blotting the Printhead with a lint-free, polyester Cleanroom Wipe. Make certain to wipe all of the exterior and interior surfaces. The Pin holes can be dried individually by using a cylindrical brush to insert a portion of the Cleanroom Wipe into each Pin hole. Alternatively, a particle-free and oil-free source of pressurized air may be used to dry the Printhead. Most laboratories contain a source of “house” pressurized air that can also be used for this purpose. The drying step is essential. Do not attempt to re-insert Pins and resume printing until the Printhead is dried completely.

9. Re-insert Pins. Once the Printhead is cleaned and dried completely, the Micro Spotting Pins may be re-inserted into the Pin holes. Make sure to insert the Pins carefully and in a perpendicular manner. Never drag the Pin tips across the Printhead surface, or insert a Pin into the Printhead at an angle. Make sure that each Pin rides up and down freely in each Pin hole. Tweezers may be used for this purpose. If one or more Pins seize or “stick” rather than riding freely, the Pin shaft may contain minor debris or residue that should be removed prior to printing. Topical Pin contaminants can be remove from the Pin shaft by rubbing the Pin shaft underneath the collar with a Cleanroom Wipe wetted with 100% ethanol. In most cases, topical ethanol cleaning suffices to remove minor contaminants and return Pins to normal function.

10. Resume printing. Once each Pin rides freely in the Printhead, printing can be resumed. Printhead cleaning should be repeated at 2-3 month intervals or as needed. Storing Printheads in a high humidity environment or splashing wash water on the underside of the Printhead are the two most common causes of Printhead oxidation. When the arrayer is not in use, make sure to keep the relative humidity as low as possible, including turning off the environmental control that is used during printing. Arrayers with sonic baths may cause splashing on the underside of the Printhead, leading to accelerated oxidation. Proper use and maintenance of Printheads and Pins will lead to years of near maintenance-free operation.