Microprocessor-Controlled Laser-Diode Particle Counters for Class 1-10,000 Cleanrooms

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit Particle Counters offer an advanced microprocessor-controlled, laser-based particle counting solution for automated particle count determination of microarray cleanrooms and other controlled environments for research, life sciences, diagnostics, pharmaceuticals, healthcare and semi-conductor applications.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Technical Notes

- Technical Assistance

- Short Protocol

- Complete Protocol

- Recommended Equipment

- Troubleshooting Tips

- Ordering Information

- Warranty

Introduction

Congratulations on taking a big step towards improving the economies of scale, quality and speed of your microarray cleanroom research. This booklet contains a complete set of illustrations and protocols describing the steps and principles needed to use ArrayIt® Microarray Cleanroom Particle Counters (MCPC and MCPC220).

Quality Control

Arrayit assures the performance of this product. The finest scientific research went into the testing of this product. Rigorous quality control monitoring and in-house programming and calibration guarantee that this instrument functions according to the highest cleanroom industry standards.

Product Description

Arrayit's ArrayIt® Microarray Cleanroom Particle Counters (MCPC and MCPC220) provides the world’s most sophisticated, laser-based, hand-held cleanroom particle counter at an affordable price. Every particle counter is programmed, calibrated and tested in a state-of-the art class 1 cleanroom. Cleanroom testing eliminates variability and uncertainty and saves time. Compare our particle counter with other commercial counters and you will see the difference.

Users will appreciate the following features of Microarray Cleanroom Particle Counter (MCPC):

- Microprocessor control for ultimate performance

- Counting precision of ±10 %

- Laser diode detection for highly accurate readings

- Rapid sample flow rate of 0.1 cfu (0.1 ft3 per min)

- Detects 0.3, 0.5, 0.7, 1.0, 3.0 and 5.0 µm particles

- Wide ambient operating temperature (15-30°C)

- Hand-held, portable operation for ease-of-use

- A/C or battery operation for convenience

- Available with 110 or 220 volt AC adaptor

- Automatic mode for simple 4-step operation (see Figs. 2-5)

- Arrives programmed, calibrated and tested

- Arrives free of biological and particulate contaminants

- Ultra-low emission of volatile organics

- Small (17 cm x 10 cm x 6 cm; L, W, H) and lightweight (1.0 kg)

- Can be connected to computers and printers

- Digital readout simplifies use

- Vast improvement over older cleanroom particle counters

- Based on years of intensive microarray cleanroom R&D

- Anti-static packaging eliminates electrostatic contamination

- Can also be used to count particles in traditional research laboratories

- The standard in the microarray industry

Technical Notes

Federal Cleanroom Standard 209E defines and evaluates cleanrooms based on the number of particles of 0.5 µm diameter or larger present per cubic foot of cleanroom air, and those same standards are used to benchmark Arrayit’s microarray cleanrooms and cleanroom products. Class 1, 10, 100, 1,000 and 10,000 cleanrooms contain fewer than 1, 10, 100, 1,000 and 10,000 particles/ft3, respectively. ArrayIt® Microarray Cleanroom Particle Counters (MCPC) are calibrated, tested and packaged in class 1 cleanrooms. The ambient air in a traditional research laboratory contains up to 1,000,000 particles/ft3 depending upon the facility.

Care should be taken never to expose the inlet tube or sensor to extremes in humidity or to solvents of any kind, and never operate the Particle Counter with the inlet tube obstructed or blocked. If the particle counter is used to monitor high particle count environments such as a standard research laboratory, it may take several counting cycles to return to the counter to “equilibrium” when reading a low particle count environment (e.g. class 1 or lower). Never submerge this electrical device. The Particle Counter contains a laser that can cause eye damage or blindness if the unit is operated with the cover open.

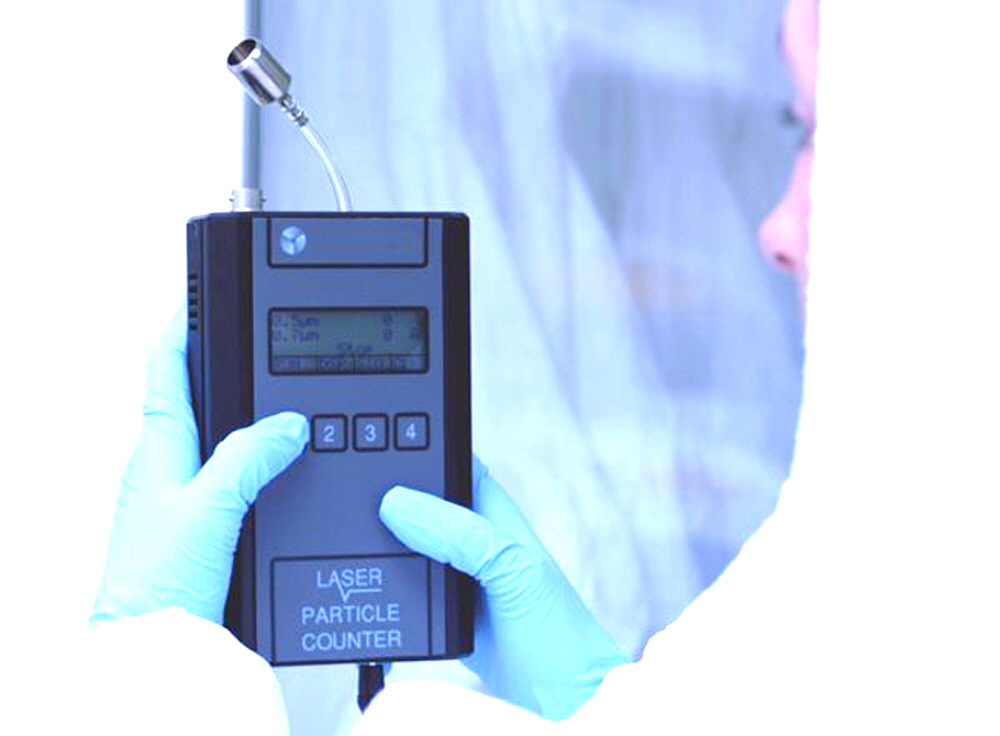

Figure 1. Microarray Cleanroom Particle Counter (MCPC) in use. Shown is laboratory technician operating the ArrayIt® Microarray Cleanroom Particle Counter (MCPC) in a class 1 cleanroom. Digital, automatic, hand-held operation allows rapid testing of any location within the cleanroom environment.

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com (under the subject heading, please type, “Technical assistance”). By telephone: (408) 744-1331, Monday–Friday, PST 9:00am - 4:30pm. Please remember that we want to hear about your successes too!

Short Protocol (Steps 1-6):

1. Decontaminate the Particle Counter packaging envelope.

2. Transport the Particle Counter into the cleanroom.

3. Connect in the AC adapter.

4. Follow the simple, 4-step counting procedure (see Figs. 1-4).

5. Re-check the particle count several times.

6. Utilize computer control and other advanced functions (optional).

Figure 2. Microarray Cleanroom Particle Counter (MCPC) being used in operation step 1. Shown is the first step of the 4-step procedure used for particle counting. The AC adaptor (cord) is inserted into the back of the Particle Counter, and power is provided to the instrument by pressing the red button.

Figure 3. Microarray Cleanroom Particle Counter (MCPC) being used in operation step 2. Shown is the second step of the 4-step procedure used for particle counting. The counting process is initiated by pressing the “Run” button, which is button number 1 on the control panel.

Figure 4. Microarray Cleanroom Particle Counter (MCPC) being used in operation step 3. Shown is the third step of the 4-step procedure used for particle counting. After the 60 second counting cycle, the particle count data are obtained by pressing the retrieve (Ret) button, which is button number 4 on the control panel.

Figure 5. Microarray Cleanroom Particle Counter (MCPC) being used in operation step 4. Shown is the fourth step of the 4-step procedure used for particle counting. The particle counts are shown for particles of 0.5 µm (80 particles/ft3) and 0.7 µm (42 particles/ft3) diameter. The 4-step counting procedure can be repeated by pressing down on the “Run” button, waiting 60 seconds for the counting cycle, and pressing down on the “Ret” button.

Complete Protocol (Steps 1-6)

1. Decontaminate the Particle Counter packaging envelope. Remove the silver-colored anti-static bag containing the Microarray Cleanroom Particle Counter (MCPC) from the shipping box. The anti-static bag prevents electrostatic and particle contamination of the Particle Counter. Do not open the anti-static bag until inside the vestibule or changing room of the cleanroom. Cover your hands with Microarray Cleanroom Gloves, wet several Microarray Cleanroom Wipes liberally with 100% ethanol, and wipe the outside of the silver anti-static package to remove particulates and other forms of debris. The anti-static packaging material should also be decontaminated with particle-free forced air for use in Class 1, 10, 100 and 1,000 cleanrooms. Forced air removes additional contaminating particles prior to entering the cleanroom facility. Make certain to wear Microarray Cleanroom Gloves at all times when handling the decontaminated anti-static packaging material or the Particle Counter. Failure to wear suitable hand protection will introduce hand oils, ribonucleases, and other contaminants into the microarray cleanroom. The Particle Counter can also be used to monitor non-cleanroom environments, and in this case may be removed from the anti-static envelope and used directly.

2. Transport the Particle Counter into the cleanroom. Transport the de-contaminated silver packaging material containing the Microarray Cleanroom Particle Counter (MCPC) into the cleanroom vestibule or changing area. Make certain to remove shoes, sweaters, and other non-essential clothing prior to entering the cleanroom changing area. Microarray Cleanroom Gloves or equivalent hand coverings should also be worn at all times when inside a cleanroom. Step into a Microarray Cleanroom Suit, making sure that the appropriate cleansuit size (S, M, L, and XL) has been selected. Close the cleansuit by zippering the front completely, and make certain that the elastic wrist and ankle bands are positioned properly. Face shields and other respiratory devices can also be worn to provide additional containment against contamination. Remove the Particle Counter and accessories from the packaging envelope and discard the anti-static envelope and the “bubble wrap”. Transport the Particle Counter, AC adaptor, stand, and pressure diffuser into the cleanroom. The Operating Guide and Maintenance Information manuals are made of paper and should not be transported into the changing room.

3. Connect in the AC adapter. Insert the AC adaptor into a standard 110-volt electrical wall outlet and connect the other end of the adaptor to the Particle Counter. The AC adapter connects to the Particle Counter on the underside, at the DC port labeled “DC PWR IN” next to the “On/Off” switch (see Fig. 2). For researchers with 220-volt circuitry, use the 220-volt AC adaptor provided with the 220-volt version of the Particle Counter (Catalog I.D. MCPC220).

4. Follow the simple, 4-step counting procedure (see Figs. 1-4). Turn the power switch into the “on” position by pressing the right side of the red power switch, as required for step 1 (see Fig. 2). Initiate the counting process by pressing the “Run” button, which is button number 1 on the control panel, as required in step 2 (see Fig. 3). After the 60 second counting cycle, retrieve the particle count data by pressing the retrieve (Ret) button, which is button number 4 on the control panel, as required for step 3. Record the data for the 0.5 µm reading, which provides a measure of the number of particles of 0.5 µm diameter per cubic foot of cleanroom air, as required for step 4.

5. Re-check the particle count several times. A total of 3-5 cycles should be used to obtain statistically sound particle count data. If multiple counts give similar readings, the data can be deemed reliable. The portable counter can be moved to different locations within the cleanroom, to access the uniformity of the air in the cleanroom facility. Cleanroom locations that give elevated readings may contain contaminated equipment, faulty filtration devices, and other sources of particle contamination. The Particle Counter can be used to identify and remedy these sources of contamination.

6. Utilize computer control and other advanced functions (optional). The ArrayIt® Microarray Cleanroom Particle Counter (MCPC) includes many additional components and functions. The portable stand (see product photo) can be used to hold the Particle Counter in place during counting cycles. The high-pressure diffuser (see product photo) can be used to monitor particle counts in sources of pressurized gas such as argon and nitrogen. A myriad of counting mode parameters can be changed using the instructions in the Operating Guide manual. The Particle Counter can be connected to a computer or printer for additional functionality.

Recommended Equipment

Microarray Cleanroom Suits

Microarray Cleanroom Gloves

Microarray Cleanroom Wipes

Super Microarray Substrates

Stealth Micro Spotting Device

SpotBot® 4 Personal Microarrayers

High Throughput Wash Station

Microarray High-Speed Centrifuge

Microarray Hybridization Cassette

Troubleshooting Tips

Anomalously high particle counts:

- Take multiple readings to ensure that the counter is at “equilibrium”.

- Make sure nothing is obstructing the isokinetic sensing probe.

Variable counts in cleanroom:

- Counts near filters and air intakes may be lower than in other locations.

- Equipment can emit particles. Check devices for particle output.

Counts exceed cleanroom class specification:

- Particle counts can vary as a function of usage, equipment, personnel and other factors. Heavy usage typically elevates particle counts above “resting”.