PRODOCUCTNAME

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarrayers - NanoPrint™ 2 LM60-2 and NanoPrint™ 2 LM210-2 Enterprise Level Linear Drive Microarray Printers

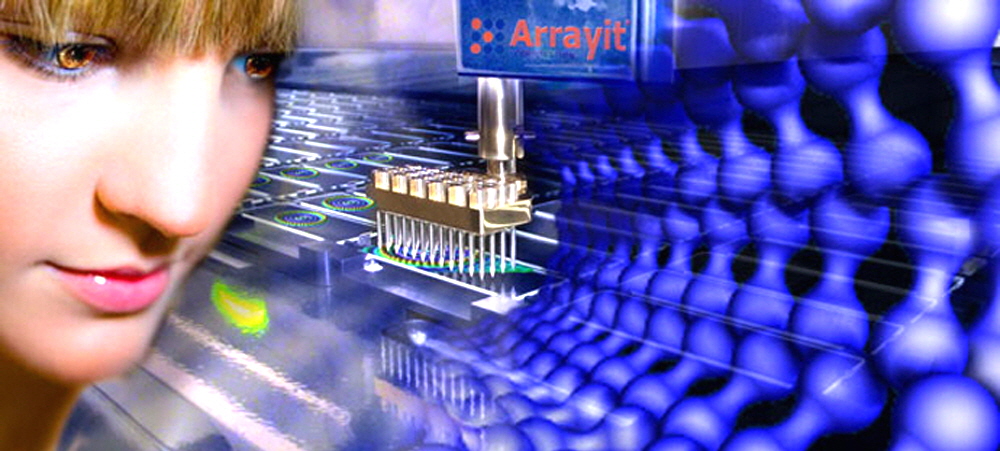

New!! NanoPrint™ 2 microarray printers build on the enterprise level linear drive systems that have provided the market’s most advanced universal platforms for microarray manufacturing for more than a decade. Based on advanced nanotechnology with version 2 motors, controllers and Ethernet connectivity, Arrayit NanoPrint™ 2 LM60-2 and LM210-2 robots offer 500 nanometer resolution and sub-nanoliter sample dispense volumes using Arrayit’s patented high-throughput contact printing technology installed in 4,200+ laboratories worldwide. Nano 2 instruments set a new standard for high-speed microarray manufacturing in research, diagnostics and pharmaceutical settings.

Click here for the NanoPrint™ LM60 and LM210 Users Manual.

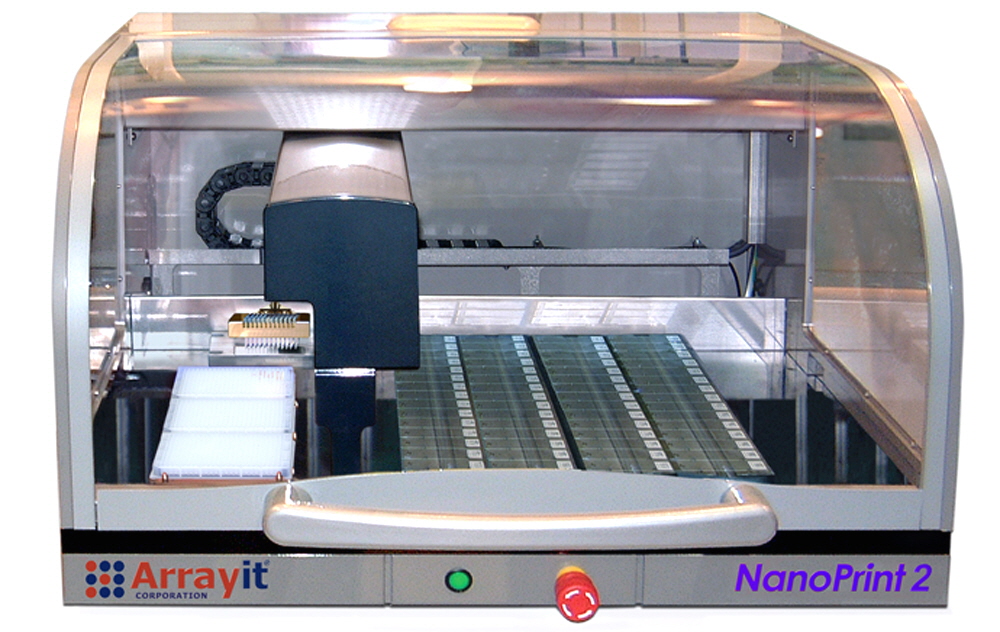

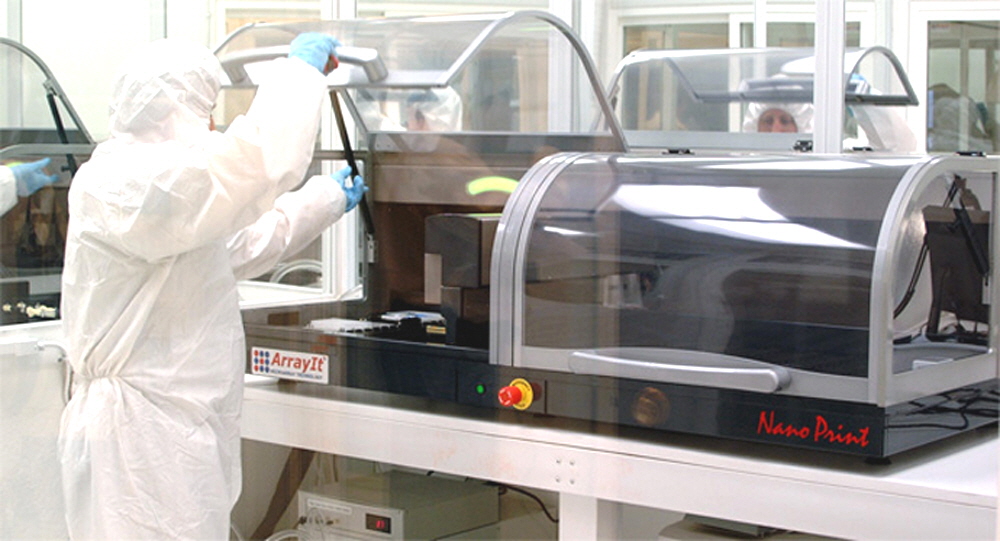

Figure 1. Arrayit NanoPrint™ 2 LM210-2 Enterprise Level Microarray Printers offer advanced version 2 linear drives, high-speed Ethernet connectivity, 3 microplates (384-well), 48 patented contact printing pins, 210 glass substrate slides (1 x 25 x 76 mm), and powerful graphical interface for high-throughput microarray manufacturing. Robotic microplate stackers with 42-plate and 189-plate capacity enable the respective fully automated printing of 16,128 and 72,576 samples.

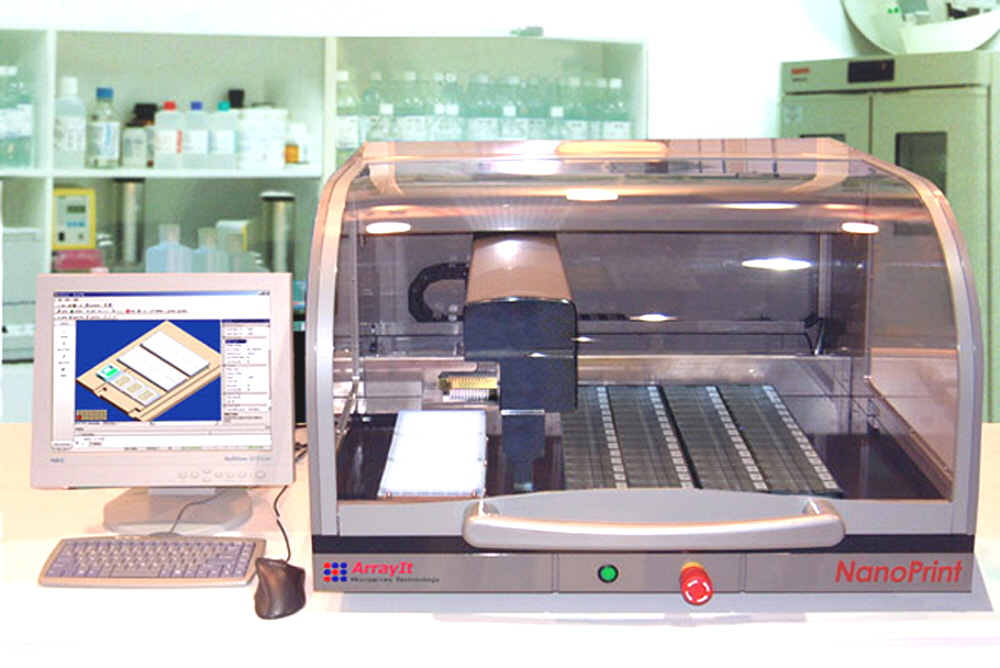

Figure 2. NanoPrint™ LM60 systems have a capacity of three 384-well sample microplates and 60 standard glass slide substrate slides. Worktables for printing into microplates, plate size glass and other micro-fluidic biochip formats are available. Our new NanoPrint™ 2 LM60 systems have next generation motors, controllers and Ethernet connectivity for faster printing from 3 x 384-well microplates onto 60 glass substrate slides.

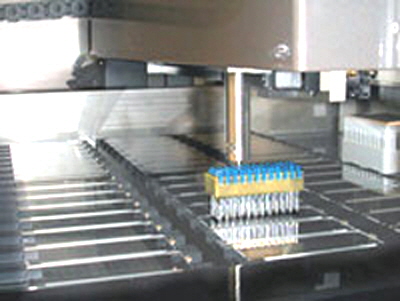

Figure 3. NanoPrint™ LM210 systems have a capacity of three 384-well sample microplates and 210 standard glass slide substrate slides. Worktables for printing into microplates, plate size glass and other micro-fluidic biochip formats are available. Our new NanoPrint™ 2 LM210 systems have next generation motors, controllers and Ethernet connectivity for faster printing from 3 x 384-well microplates onto 210 glass substrate slides.

Figure 4. Shown is the NanoPrint™ LM210 system with a capacity of three 384-well sample microplates printing onto 210 standard glass slide substrates.

NanoPrint™ Microarrayers are industrial-level platforms for all microarray manufacturing applications including DNA microarrays, protein microarrays, and other types of biomolecules. NanoPrint™ systems enable the manufacture of microarrays utilizing ArrayIt® Professional, 946 and Stealth Style Micro Spotting Pins. The NanoPrint™ uses superior linear drive motion control technology and proprietary Warp1 controllers, and is compatible with all standard microarray surfaces made by ArrayIt® and other glass substrate slide open platform vendors. Systems are easily configured to print onto different types of surfaces including 96 and 384-well plates, plate-sized glass, and proprietary cartridges and cassettes by taking advantage of flexible and modular deck configurations and an easy to use software interface. The Microarray Manager Software combines unparalleled power and simplicity in a graphical user interface. Click here for a NanoPrint™ Microarray Manager Software tutorial.

NanoPrint™ Microarrayers are industrial-level platforms for all microarray manufacturing applications including DNA microarrays, protein microarrays, and other types of biomolecules. NanoPrint™ systems enable the manufacture of microarrays utilizing ArrayIt® Professional, 946 and Stealth Style Micro Spotting Pins. The NanoPrint™ uses superior linear drive motion control technology and proprietary Warp1 controllers, and is compatible with all standard microarray surfaces made by ArrayIt® and other glass substrate slide open platform vendors. Systems are easily configured to print onto different types of surfaces including 96 and 384-well plates, plate-sized glass, and proprietary cartridges and cassettes by taking advantage of flexible and modular deck configurations and an easy to use software interface. The Microarray Manager Software combines unparalleled power and simplicity in a graphical user interface. Click here for a NanoPrint™ Microarray Manager Software tutorial.

Software features include:

- A Method Creation Wizard

- User & version control management

- Custom calibration of the slide and microplate positions

- Complete sample tracking

- Support of input and output data files

- Custom microarray designs

- Customizable speed profiles and wash protocols

- Automatic Method Validation

- Runtime sample and spotting views as well as a Simulation Mode

- Easy to use graphical Re-Print Wizard

The high speed, high precision linear servo control system of the NanoPrint™ produces superior instrument performance that is essentially free of friction, noise and thermal emission. Combined with the compact bench top design, user configurable worktable, humidity and particulate control, a host of available options, and the flexible and sophisticated software, NanoPrint™ systems offer the complete solution to high performance microarray printing.

NanoPrint Options:

- 192 Pin Printhead (48 Pin Professional Printhead provided as standard)

- Anti-vibration table

- Peltier-driven microplate cooling

- Microplate printing worktables

- Custom worktables for proprietary printing cassettes, biochips and cartridges

- Worktable conveyor

- Microplate stackers, refrigerated with lid removal and barcode reader

- Dehumidification

- Extended service warranty

The value of the linear servo motor technology used on NanoPrint™ Microarrayers:

- Nanometer scale positional accuracy

- Quiet operation

- No vibration

- No heat generation

- No motor dust

- Superior Accuracy

- Near maintenance-free operation

- High speed

- High load capacity

- Zero "sagging" with loss of power

- Safer and much more durable than stepper motors

Specifications

Software |

|

Interface |

Intuitive and Graphic Windows 10 User Interface |

User Management |

Password protected access levels for User, Manager and Administrator |

Data Files |

Both import and export of data files compatible with all current microarray detection instruments |

Version Control |

Complete tracking of all methods, version and backups |

Automatic Method Validation |

Automatically validates for compatible method parameters |

Sample and printing Views |

Each available in real-time during operation |

Method Creation Wizard |

Only minimal information required to create microarray printing protocols |

Simulation Mode |

Pre-test print methods in software prior to running programs |

Flexible |

Microarray design, pin configuration, worktable layout, source and destination type, offsets, speed profiles, wash/dry parameters and pre-print locations |

Hardware |

|

Size (L x W x H, cm) |

LM60-2 (110 x 85 x 56 cm), LM210-2 (164 x 85 x 56 cm) |

Weight (kilograms) |

LM60-2 (150 kg), LM210-2 (200 kg) |

Positional resolution |

500 nanometers using linear drive Warp2 control |

Printing speed |

96 spots per second or 192 Spots second using “192” Series Pins and Printheads. |

Destination |

Microarray substrates, glass slides, microplates, custom |

Printing technology |

Arrayit Pro, 946 or Stealth pins and printheads |

Number of pins |

Configurable 1 to 48 at 4.5 mm centers or 1 to 192 at 2.25mm |

Spot diameter |

37.5 microns or larger to meet all applications |

Minimum spot spacing |

50 microns |

Pre-printing |

User definable |

Wash/Dry station |

Ultrasonic with 2 wash positions and a dry station |

Number of microplates |

Three standard 384-well, customizable |

Number of substrates |

60 substrate slides (LM60-2) or 210 substrate slides (LM210-2) |

Number of microplates |

15 96-well microplates (LM60-2) or 45 96-well microplates (LM210-2) |

Microplate type |

96-well or 384-well microplates |

Microplate cooling |

Cool 1-3 microplates, for protein microarray applications, or use the refrigerated stacker for higher throughput and hands free automation. |

Environmental control |

Fully enclosed, HEPA filtration and user-defined humidity control |

NanoPrint™ 2 Flexible Deck Configurations: Front left view of the NanoPrint™ showing three microplates, the wash/dry module and the printhead and pins printing onto glass substrates. A 48-pin NanoPrint printhead loaded with 48 946 Micro Spotting Pins is printing location 8 on the deck. The modular deck design and platen cassettes allow users to easily switch between glass substrates, microplates, wafers and other types of substrates. |

|

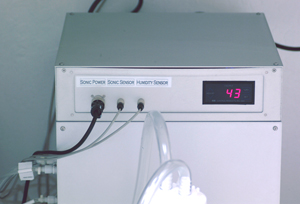

Accessory Control Module (ACM): The ACM unit provides computer control for the wash/dry, humidity, and ultrasonication stations on the deck of the NanoPrint™. The ACM unit fits neatly beneath the laboratory bench or under the optional anti-vibration table available with the system. The ACM is extremely quiet and operates only as needed by the system. Humidity is maintained in a user-specified manner of ±1%. Wash buffers are stored in carboys in front of the ACM. |

|

NanoPrint™ 2 Pin Cleaning Module: NanoPrint™ 2 microarrayers are each equipped with a station that provides pin washing, drying and sonication of 1-48 pins. The sonicator is automatically filled and emptied during the print run in a completely automated manner. Systems sensors prevent splashing and overflowing for pin and deck safety. Drying is accomplished by vacuum using a quiet but powerful ACM-controlled function. The Pin Cleaning Module is rugged, durable and easy to maintain. |

|

NanoPrint™ 2 ACM Connectivity: Easy connectivity between the ACM and the robot and accurate sensing of the humidity inside the chamber assures that proper humidity levels are achieved and maintained during the entire duration of each print run. Dehumidification is an option available at an extra cost and is highly recommended for users who wish to operate their systems in humid environments. The humidification and dehumidification systems are triggered by sensors that automatically maintain the levels set by the user. |

|

NanoPrint™ 2 Humidity Sensing: Accurate sensing of the humidity inside the chamber assures that proper humidity levels are achieved and maintained during the entire duration of each print run. Dehumidification is an option available at an extra cost and is highly recommended for users who wish to operate their systems in humid environments. The humidification and dehumidification systems are triggered by the RH sensor that automatically maintain the levels set by the user. |

|

NanoPrint™ 2Microplate Peltier Cooling: NanoPrint™ systems offer sophisticated microplate cooling via Peltier as an affordable and highly recommended option for users wishing to minimize sample evaporation during printing. Microplate cooling is also highly recommended for protein microarray applications to minimize protein denaturation and microbial growth in recombinant protein samples. The Peltier module fits directly beneath the microplate for highly efficient cooling while maintaining a low deck profile. |

|

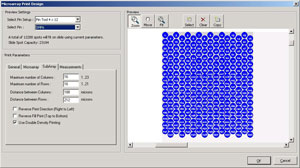

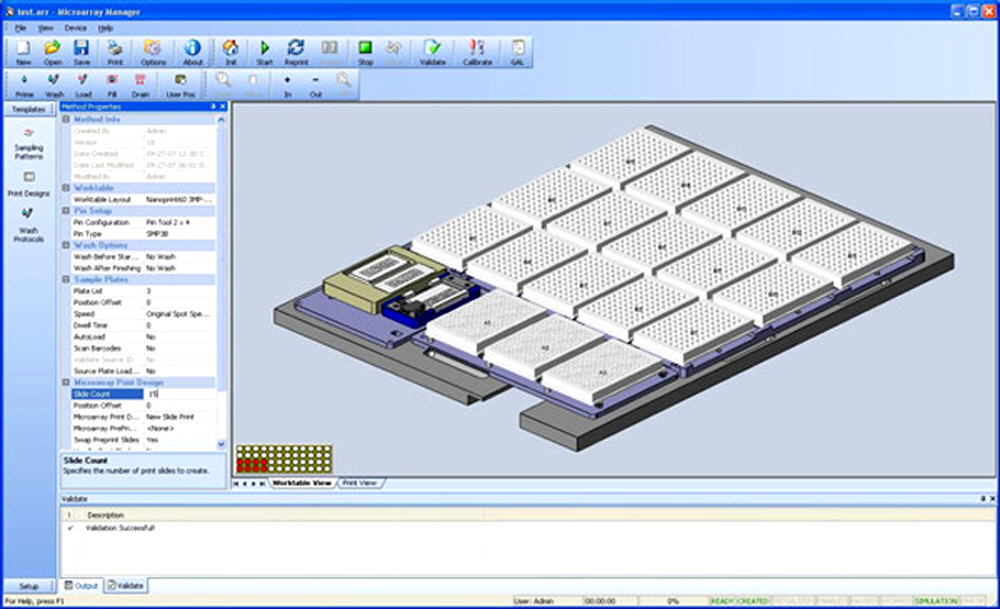

NanoPrint™ 2 Software: The extraordinary and highly intuitive graphical user interface provides users with software writing speed, power and flexibility. Shown here is a screen shot of the interstitial printing software command that automatically directs the robot to deposit the printed spots into a “orange packing” configuration for dramatically increased microarray printing density. |

|

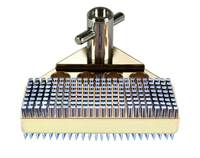

48 and 192 Pin Configurations are now available. 192 Pin configuration allows the user to run from 1 to 192 pins at 2.25 mm center to center spacing to pickup samples from 1536 well plates. Standard deliverable is 48 Pins at 4.5mm centers for use with 384 well plates (96 well plates can also be configured). NanoPrint™ 2 software and unique Pin and Printhead design allows the end user to setup the pin tool any way that they like. Multiplex array processing systems, plates, biochips micro fluidics, and cartridges can all be easily configured. |

|

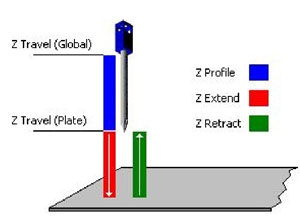

Superior Z-Axis Resolution for Optimum Spot Morphology: The Z-axis encoder on the NanoPrint™ 2 reads at 250-nanometer resolution. Unlike belt and stepper motor driven Z-axis motion control, the NanoPrint™ offers highly precise resolution, repeatability and computer control over the speed and acceleration settings to ensure optimal printing onto any surface using our patented contact printing technology. Optimal parameters are set at the factory but can be easily changed by the user for printing onto many different surfaces. |

|

Figure 5. The NanoPrint™ 2 deck is configured in a module manner, allowing different worktables to be inserted and removed from the deck for different printing applications such as glass substrates, microplates, and proprietary cassettes and cartridges. The screenshot shows a worktable allowing printing into 15 microplates (96-well) for the NanoPrint™ 2 LM60-2.

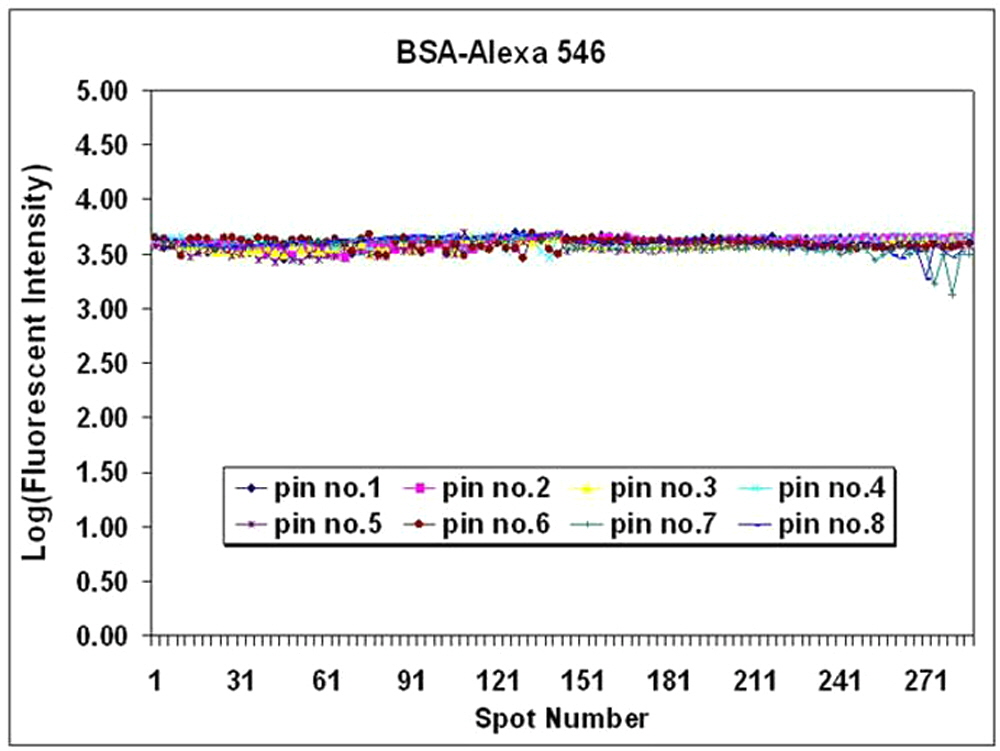

Figure 6. Data showing the printing consistency of eight different SMP3B pins in a single print run using the NanoPrint™ 2 LM60-2. The data were provided courtesy of W.G. Shreffler and L. Bardina at the Mount Sinai School of Medicine (New York, USA).

Figure 7. Shown is the NanoPrint™ LM210 system configured in an ArrayIt® class 1 cleanroom. The entire deck is accessible via two doors that open and close independently for user convenience and safety. The top of the Accessory Control Module (ACM) is shown beneath the robot.

Figure 8. Shown is the NanoPrint™ LM210 system configured in an ArrayIt® class 1 cleanroom. Microarray manufacturing parameters including the number of pins, substrates, spots, technical replicates, printing pattern, worktable, printing offsets, speed, acceleration, and many other technical aspects are completely controllable by the operator via an intuitive graphical user interface (GUI). The NanoPrint™ MicroarrayManager Software allows users to write completely customized printing routines in minutes. Worktables allow the user to switch between glass substrate slides and microplates using different worktables and software routines.

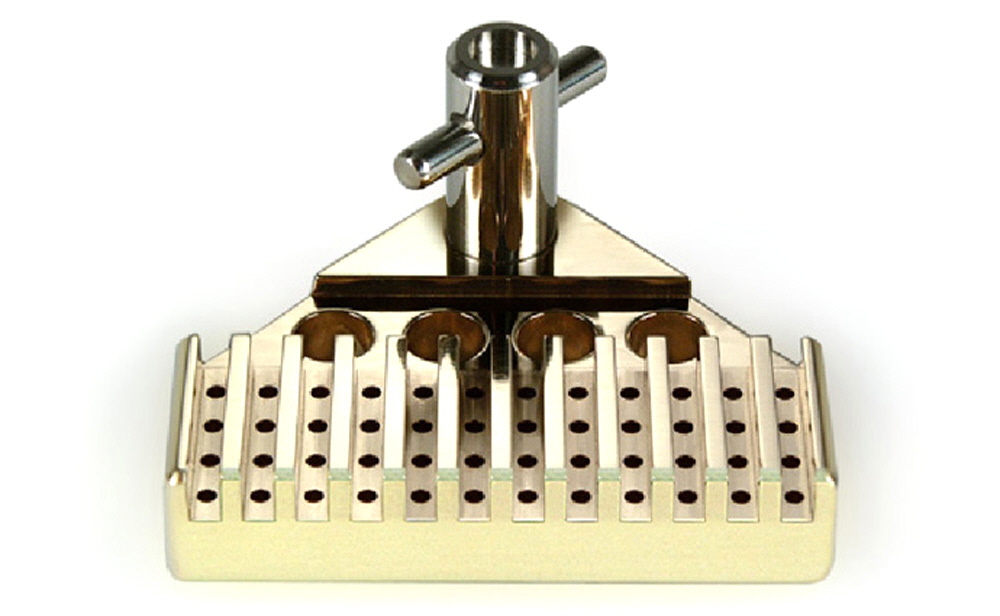

Figure 9. Shown is the NanoPrint™ 2 48-pin printhead designed to hold up to 48 microarray printing pins of the Professional, 946 or Stealth series. The attachment bayonet allows the printhead to be attached and removed for cleaning easily and precisely, eliminating the need for system re-calibration.

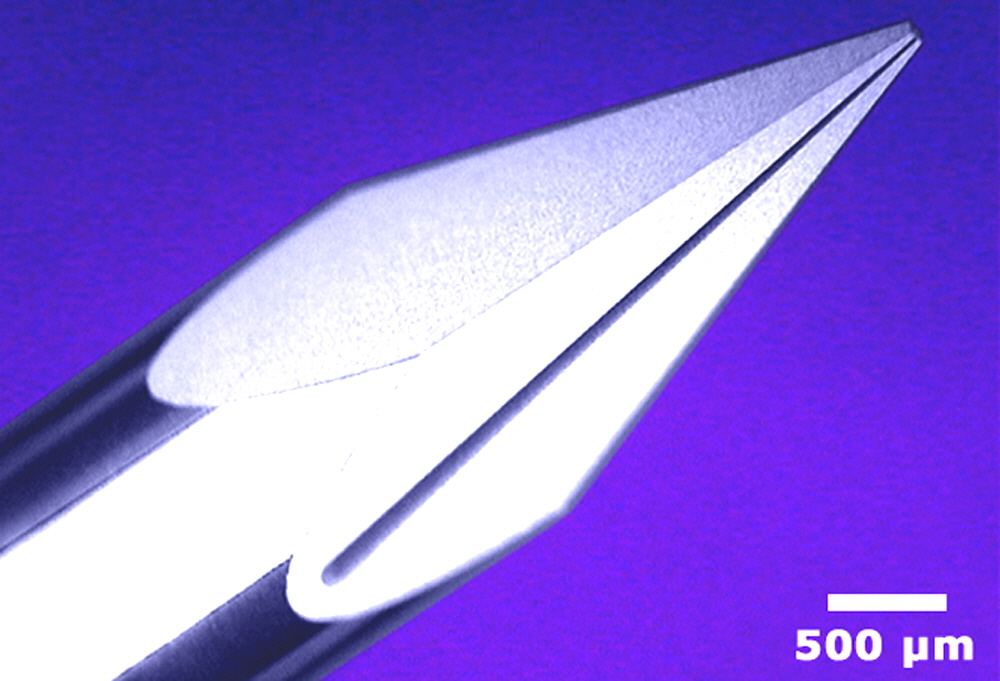

Figure 10. Shown is the point of a Professional Series 3 (Pro3) microarray printing pin. Samples load into the pin uptake channel by capillary action, and direct contact between the sample layer on the pin tip and the glass printing substrate results in the formation of a printed microarray spot. The NanoPrint™ 2 LM60-2 and LM210-2 systems control pin movements in 500 nanometer increments for unsurpassed printing precision at speeds of 48 spots per second. A total of 48 microarray printing pins of any tip size from the Professional, 946 or Stealth series may be used on our NanoPrint™ 2 systems.

Figure 11. Shown is the Worktable Workstation for the NanoPrint™ 2 LM60-2 and LM210-2 systems. The Worktable Workstation allows fully automated conveyor-based loading and unloading of glass slide substrate, microplate, and custom worktables from the NanoPrint™ 2 deck. With a capacity of 60 worktables, the WorkTable Workstation allows fully automated printing onto 1800 glass substrates, 300 96-well microplates, or 900 custom cassettes by special purchase quoted separately from standard NanoPrint configurations.

Figure 12. Shown here is 24 microarrays per slide substrate, a popular format easily setup and executed using the NanoPrint™ 2. This format is compatible with the AHC4x24, AHC1x24, and RC1x24 hybridization reaction tools. Using this format and an NanoPrint™ 2 LM210-2 Microarrayer enables the automated manufacturing of more than 5,000+ microarrays per run and 1,400+ using a NanoPrint™ 2 LM210-2.

Figure 13. Arrayit NanoPrint™ 2 LM60-2 and LM210-2 Enterprise Level Microarray Printers move in nanometer increments and delivery nanoliter droplet sizes to empower a range of nanotechnology applications.