Microarray Printing Technical Guide

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Microarray manufacturing contact printing spotting pins printheads tutorial life sciences research

Tools - Microarray Printing - Microarray Printing Technical Guide

To download the PDF file on how to Print High Quality Microarrays please click on the link below:

Printing High Quality Microarrays

Introduction

These are the five key components to manufacture high quality microarrays. They are:

1. Motion Control System (Microarrayer)

2. Micro Spotting Pins

3. Sample Preparation

4. Substrate Surface Chemistry

5. Printing Environment.

If any of these five criteria are not optimized, the quality of microarray printing will be compromised. Use this guide to diagnose the microarray manufacturing problems.

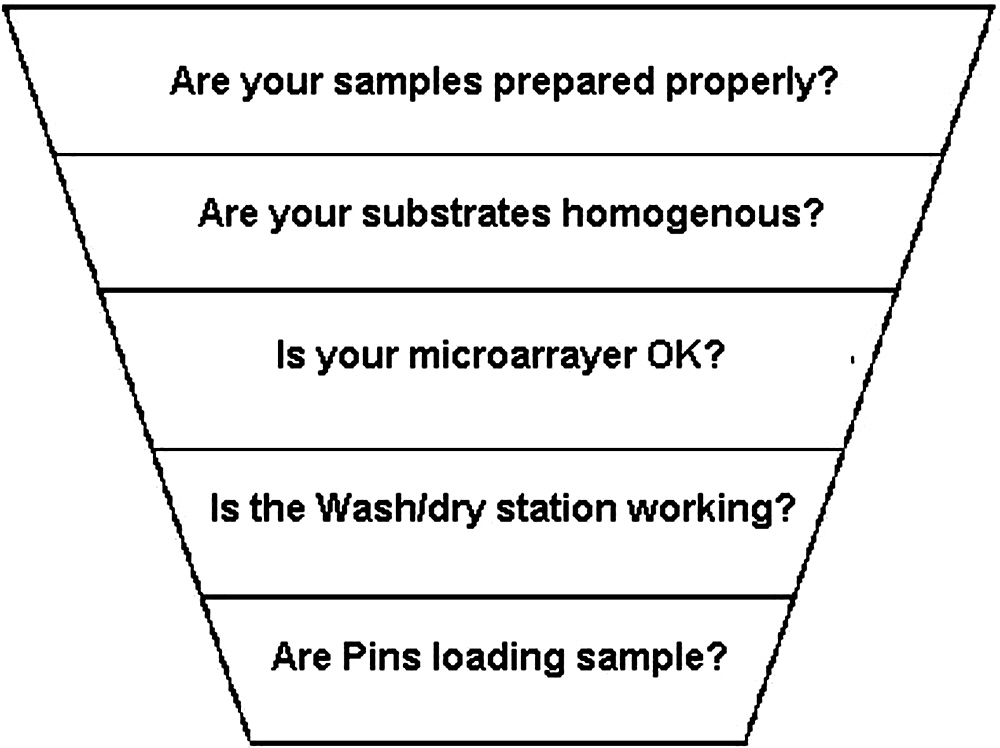

Technical Trapezoid

Based on many hours of printing trials, theoretical modeling and feedback from thousands of customers, we have been able to establish a diagram that lists the most common sources of printing problems posed as a series of questions (Fig. 1). If you’re not getting good printing, start by examining the Micro Spotting Pins under a dissecting microscope and go from there. the problems will be easily diagnosed and solved if you are able to answer “yes” to all of these questions.

1. Are the Pins loading sample?

Physically damaged Pins, Pins clogged from poor cleaning; Pins or Pins clogged with contaminated samples are common sources of irregular printing. Arrayit digitally measures each Micro Spotting Pin we sell. We have removed the mechanical differences from Pin to Pin that can cause irregular printing. However, miss-handling Pins, Pins clogged with sample, and Pins with contaminated surface tension properties are some common causes of printing problems. If you know the microarrayer is behaving itself, check the Pins under a dissecting microscope. Are they clean and free of contamination? Is there any physical damage to the Pin? If they are physically damaged, the tips are too small to repair. For an image of what a micro spotting pin should look like please view Figure 4. If the Pins are not loading sample and are not physically damaged, follow these procedures to prepare the Micro Spotting Pins to print virtually any type of sample. It is also recommended to use this cleaning procedure after every print run. This cleaning procedure takes only 15 minutes.

Step 1. Wear powder free nitrile gloves through this entire process. Sonicate the Pins in a 2-5 % concentration of Micro Cleaning Solution (Arrayit catalog # MCS) being sure the Pins are suspended in the sonication bath and not touching the sides or bottom of the bath. For best results use the kit, see details by clicking here. Typically 5 minutes is long enough, but severely abused Pins that have had samples allowed to dry on the Pins may require longer sonication.

Step2. Rinse in hot tap water until all MCS is completely rinsed away. 2 minutes

Step 3. Sonicate for 3 minutes in distilled water. Never expose the Pins to de-ionized water. De-ionized water pulls ions out of the stainless steel of the Pins and promotes corrosion.

Step 4. Blow dry with clean forced air. Do not use air from canisters; the propellants will ruin the surface tension properties of the Pins.

Step 5. Put the protective caps on the Pins now and they are ready to load into the robot and be used or tested. A storage box can be a helpful tool, click here for details.

You can easily determine if the pins are printing by observing the spotting of the solution while the pins are arraying the samples. Arrayit's Micro Spotting Buffers (MSS, MSP, and PPB), and most other spotting buffers leave visible ‘dots ’ during the arraying process. These 'dots' are due to the salts in the solution and will disappear during processing of the arrays leaving an invisible array of the attached DNA on the microarray substrate. After printing you can hold the array up to a light source and usually visually determine if the spots were printed, and if there are any gross defects such as spot merging, or missing spots. Finer evaluation of the array may require hybridization with a fluorescent labeled probe (protocol here).

2. Is the wash/dry station working??

Pins must be completely clean and dry in order to load a new set of samples. If they are not, they will not load completely. Pins that do not load completely with sample will run out of sample prematurely. A good wash dry station for a microarrayer can be seen here.

3. Are the samples prepared properly?

Often a printing problem can be blamed on damaged or contaminated Pins, but the real culprit is sample preparation. The smaller the assay, the cleaner the samples have to be. If PCR products are being spotted, neither ethanol precipitation nor kits that use size exclusion as a purification method are recommended. These methods can leave trace contamination that can clog Micro Spotting Pins and inhibit DNA attachment to the printing substrate. The use of membrane binding purification methods such as Arrayit’s PCR Purification Kit is recommended.

Included in sample preparation is having a consistent concentration and proper volume of DNA in each well of the sample pickup plate. Large variations in concentrations from well to well will result in irregular spotting and hybridization. Also, amounts larger than 1 mm layer thick of sample in the sample pickup plate can cause large spots. The cause of this is too much sample sticking to the outside of the Micro Spotting Pin. To achieve good printing, use ~10 micro liters of sample in a 384 well polypropylene round or v bottom plate.

4. How about the substrates?

A high quality microarray is defined by having the same amount of DNA at each array location on the printing substrate. If the substrate is not homogenous, meaning that it does not have the same amount of reactive groups at each array location on the substrate, then different amounts of DNA will attach to the surface. Arrayit does not recommend using microscope slide glass as a printing substrate. By nature, standard microscope slide glass is not homogenous. Therefore, we have implemented the use of optical quality glass processed in a cleanroom to assure that when we derivatize the surface with either epoxide, aldehyde or amine reactive groups we get a homogenous surface. Start with microscope slide glass quality, get a microscope

quality, start with optical quality glass, and get an optically homogenous surface. It is also important for consistent delivery of sample to have a flat printing surface. Not only are standard microscope slides non-homogenous; microscope slide glass does not have consistent physical dimensions. Using a micrometer, we have measured microscope slide glass and have seen more than 50 micro differences in thickness from slide to slide. The difference in thickness changes the dwell time of micro spotting Pins on the surface. The longer the Pin touches to the surface, the more sample gets delivered. Without a flat printing surface, it’s more difficult to get a consistent delivery of sample.

5. Is the robot OK?

The most obvious component to good printing is the robot. In addition to having precise repeatability and a good wash and dry station for Pins, a microarray must have a clean and enclosed humidity controlled environment. Use humidity between 55-65%. We recommend not less that 10-micron repeatability/accuracy in all three motions x, y and z. Currently most of the commercial and some non-commercial microarrayers meet these criteria. We recommend that you don’t try to convert a legacy liquid handling system into a microarray robot; most of them don’t have enough accuracy. If you’ve got a printing problem, check the wash/dry station of the robot to make sure it is functioning properly. Micro Spotting Pins must be completely clean and dry in order to load properly.

Spot Size

Factors that define spot size.

1. Size of the end of the tip

a. Larger tips make larger spots and visa versa

2. Dwell time of the pin on the surface

a. The longer a Pin touches the surface, the more sample will be delivered

3. Viscosity of the sample

a. More viscous samples will make smaller spots

4. Hydrophobicity of the substrate

a. The more hydrophobic the surface, the smaller the spot

Summary

This list discusses the factors to monitor to produce high quality microarrays. If these factors are controlled, we can guarantee that you will be able to manufacture high quality microarrays. Many of these steps are difficult to control when “homemade” systems, slides and purification systems are used. With Arrayit producing affordable and high quality products to use, the steps get a lot easier to control. For more details download our presentation by clicking here.

To order ArrayIt® Brand Products email arrayit@arrayit.com

Research Use Only

Arrayit microarray printing technology (U.S. 6,101,946) is sold for research use only.