Liquid Handlers

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Microarray Lynx LM linear drive liquid handling workstations 96-well pipetting plate handling 600 1200 mm life sciences research

Instruments - Microarray Processing - Lynx Linear Drive Liquid Handling Workstations

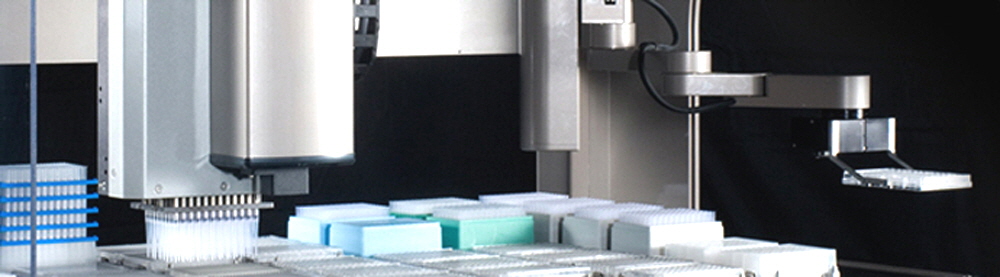

The Lynx LM Series is a versatile and robust linear motion (LM) open platform for any liquid handling application, providing state-of-the-art performance in precision and accuracy. Compared to the industry standard belt driven and rotary motor & encoder system, the non-contact brushless linear motor with linear encoder motion control technology of the Lynx LM provides superior speed and positional accuracy, down to 1.0 µm repeatability at 2G of acceleration.

Method Manager provides a graphical user interface for controlling the Lynx LM Series instrument that facilitates the liquid handling needs of a wide range of life science applications, including both routine and research activities. Method Manager can either be used stand alone for controlling Lynx LM Series pipetting instruments or together with a third party scheduling package.

Method Manager allows the user to develop custom pipetting scripts and to quickly visualize how a process can be implemented. Script commands are provided for a wide range of hardware options and the scripting system is designed for maximum flexibility when developing complex custom scripts. When the script is ready, Method Manager controls the pipetting run by sending control signals to the instruments through an RS-232 data connection. If operator interaction is necessary, Method Manager can display a dialog box on the display of the workstation which prompts for the information which is needed.

Combined with the extensive host of available Options & Accessories, the Lynx LM platform is a compact and powerful bench top workstation. Offering two instrument sizes (1200 and 600 mm), up to two tool arms on LM 1200, up to 14 axis of freedom, forty-two micro plate positions, a Quick Deck conveyor based plate transport and a menu of available pipetting tools, accessories & configurations.

The designation of the model number 600 and 1200 represents the width of the chassis (in millimeters) of the two currently available Lynx LM Series Platforms. The remaining chassis dimensions are otherwise equivalent between the two available platforms. The Lynx is referred to as a platform rather than a pipettor as it provides a versatile base instrument by which a wide variety of applications may be developed. Both the software and instrument chassis provides simple external integration capabilities with all four sides of the worktable accessible by the use of existing laboratory stacker and gripper systems. Currently, the product is offered with the capability to configure any combination of available or custom arm tools providing further versatility for application development.

Lynx Standard Pipetting Tools

The Lynx offers three standard multi-channel pipetting tools including two 96-Tip and one 384-Tip pipette head. There is also a standard 8-Tip tool for volumes up to 1 mL primarily utilized for IC-50 or serial dilution column-wise applications. The standard 96 & 384-Tip pipetting tools have consistently provided impressive pipetting results in field head-to-head comparisons performed by end users when compared with leading competitors such as the Beckman FX, Tecan Aquarius and PE Evolution. Typical results indicated Imprecision CV's of the Lynx to be approximately 1/2 of the competitive product with the Lynx CV's of ~5% at 1 µl for the 96-Tip and ~8% for the 384-Tip.

Although both the 96 & 384-Tip pipette heads are rated down to 500 nL, we can successfully implement smaller volumes down to 200 nL. The Lynx currently utilizes commonly market available 96 & 384 disposable tips in an effort to offer end users the lowest possible disposable costs as well as available features & sizes. Alternatively, the pipette tip cones from the pipette heads could be re-designed to specific custom disposables to both manage the distribution and capitalize on the disposable income.

In addition, there are Robotic Pin Tools commercially available that are offered for nL level plate to plate transfers that are supported on the Lynx LM Series. These tools cover the volume range from 2 nL to 5 µL and are available in 96, 384 & 1536-Pin models.

Features

- Bench Top - Gantry Robotic Workstation

- Linear Motor Motion Control

- Up to 42 Microplate Positions

- One or Two Tool Arm Configuration

- Custom Tool Configuration

- Quick Deck Compatible

- Multiple Options and Accessories

- Easy Integration with Third Party Devices

- Available in Two Deck Sizes: 600 mm and 1200 mm

Accessories

- Quick Deck System

- Microplate Workstations (SBS Standard)

- Reagent Reservoirs (Auto Refill and Auto Circulating)

- Heating/Cooling Stations

- 96/384 Tip Wash Station and Controller

- Vacuum Filtration Station

- Reagent Stir Station (Magnetic)

- Sonication Station

Robotic Arm Tools

- 8 channel, bulk reagent dispenser

- 8 channel, standard volume (5-200 µl), disposable tip, pipette head

- 96 channel, standard volume (5-200 µl) , disposable tip, pipette head

- 96 channel, low volume (0.5 - 40 µl), disposable tip, pipette head

- 384 channel, low volume (0.5-40 µl), disposable tip, pipette head

- 384 pin tool, volume ranges 2 nl to 5 nl

- 1536 pin tool, volume ranges 2 nl to 5 nl

- Microplate gripper

- Custom tools available