Imprinters

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Arrayit | Microarray imprinters manual hydrophobic well barriers 1x25x76 mm glass slides multi-well microarrays life sciences research

Instruments - Microarray Processing - Microarray Imprinters for use with Microarray Slides

Create your own hydrophobic well patterns for numerous microarray applications. Arrayit Microarray Slide Imprinters offer an easy and cost effective way to partition microarray slides and substrates with a hydrophobic pattern for microarray and other slide based applications. This durable instrument is ideal for high throughput microarray experiments where multiple assays need to be run on a single microarray substrate slide with minimal risk of contamination between wells.

The Microarray Substrate Imprinter is a unique substrate slide partitioning technology that empowers the researcher to create microarray “wells” on virtually any microarray substrate slide.

Gaskets and other approaches

Gaskets without adhesive may not seal completely if the hardware is not designed properly and over time gaskets can wear out. If you prefer a high quality gasket type system, click here. Gaskets with adhesive can leak if the adhesive is soluble in the solvents used in processing the microarray. Gaskets must be removed before scanning which can cause some types of microarray surface chemistries to peel off the surface. Hydrophobic markers such as PAP pens are tedious and difficult to apply, are soluble in certain solvents, and the resulting partitions are often inaccurate. Some manufactured barriers are expensive, must be ordered in quantity, and design changes can be difficult and time consuming to implement.

Number of microarray “wells” per substrate slide |

Reaction volume per microarray well |

Estimated number of microarray spots per well |

12 |

40 µl |

500 |

16 |

60 µl |

750 |

24 |

60 µl |

500 |

48 |

6-7 µl |

48 |

192 |

1-1.5 µl |

16 |

End users will appreciate the following

- imprint hydrophobic patterns onto any slide and surface (any design/pattern can be imprinted)

- empowers high throughput sample processing

- pays for itself quickly by amortizing surface chemistry cost over many microarray experiments on a single slide/substrate

- patterns meet micro spotting pin spacing of all Stealth and 946 printheads and microarrayer programming

- parallel loading of samples using multi-channel pipettes or automated pipetting liquid systems such as Oasis and others

- does not contribute to background or light scattering in scanning for colorimetric, CCD and laser/pmt fluorescent microarray scanners

- stays on throughout all microarray processing and detection steps

- compatible with a wide variety of aqueous and solvent based buffers

- works for both DNA, protein, carbohydrate, small molecule and other types of microarrays

- easy to use, no setup or assembly required

- fast, each slide only takes a few seconds to imprint

- fun to use

- works with any and all microarray surface chemistry including hydrogels and membrane based surfaces such as SuperNitro and SuperProtein

- inexpensive, low cost to operate and own

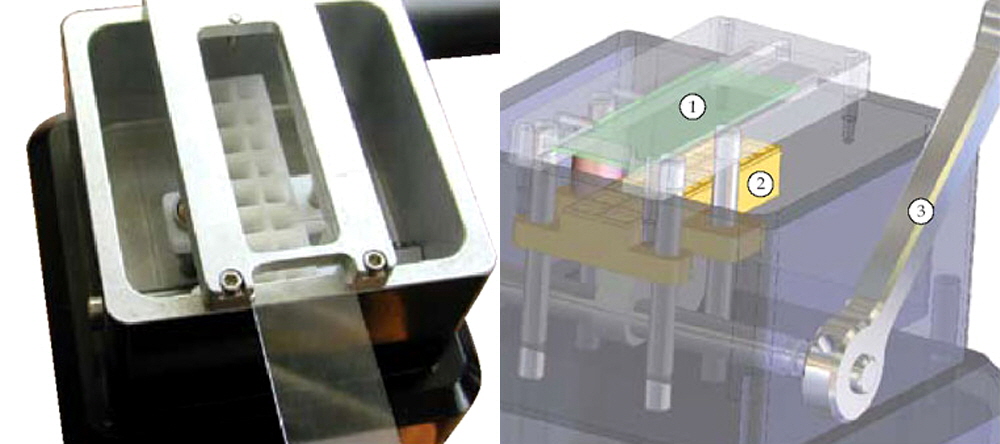

How the Microarray Slide Imprinter works

The Microarray Slide Imprinter provides a fast and convenient way to define multiple “wells” on a single microscope slide size substrate to create separate regions for many assays on a single substrate. This is accomplished by imprinting a thin, inert, hydrophobic film patterned onto the surface of a substrate slide using of a stamp to create individual reaction “wells”.

Step 1. Select a stamp and make sure it is immersed in a bath of hydrophobic film polymer (left). Step 2. Insert a 25 x 76 mm glass substrate slide into a cartridge above the bath to hold it accurately for consistent positioning and imprinting, allowing consistency from slide to slide (left). Step 3. Pull the lever on the outside of the imprinter so that the stamp contacts the surface of the substrate and imprints the desired hydrophobic barrier lines onto the substrate (right). Once the hydrophobic barriers dry, the microarrays can be manufactured and processed.

Since the printed hydrophobic pattern printed is thin, the imprinted slides/substrates can be inserted directly into microarrayers and microarray processing racks and wash stations and directly into a microarray scanners without any further modifications. The coating is highly hydrophobic, does not dissolve in most solvent systems, and will stay on the slide through multiple wash steps and overnight incubations. The Microarray Slide Imprinter offers excellent flexibility. The imprinted hydrophobic barriers can be made in any design and works with all microarray surface chemistries including membranes and hydrogels. Additionally the barrier shows excellent stability in most solvents through repeated washes, is chemically inert and does not contribute to light scatter or background noise in detection.

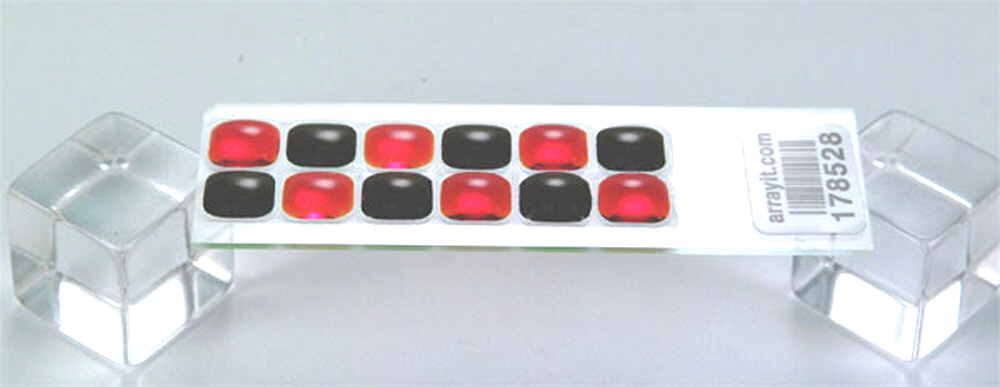

Image of a 12 well imprinted slide using food coloring for visual effect to show how the different areas of the slide will not cross contaminate.

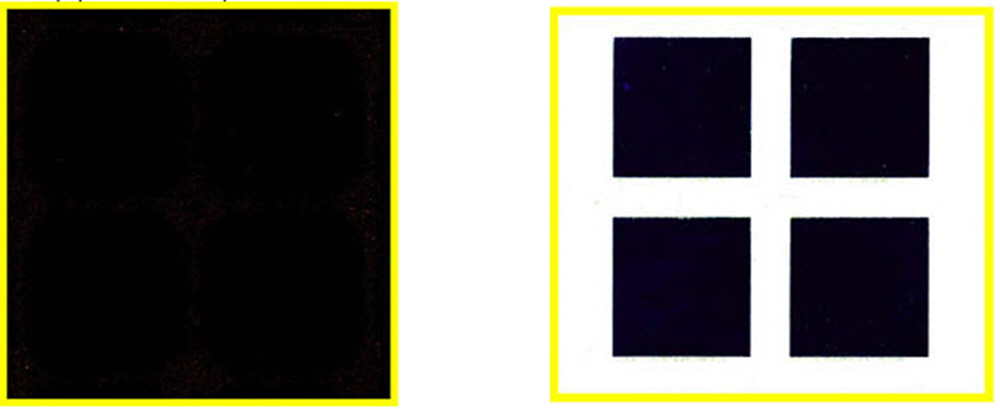

Background light scattering comparison between imprinted microarray slide (left image) and a slide with common hydrophobic ink (right image) scanned with a typical laser/pmt microarray scanner. Yellow border added for visualization of data. Note that the imprinted pattern on the slide (left image) does not show up in the scan and therefore does not contribute to background noise nor does it scatter any signal. Border on the ink printed slide shows completely saturated signals (right image).

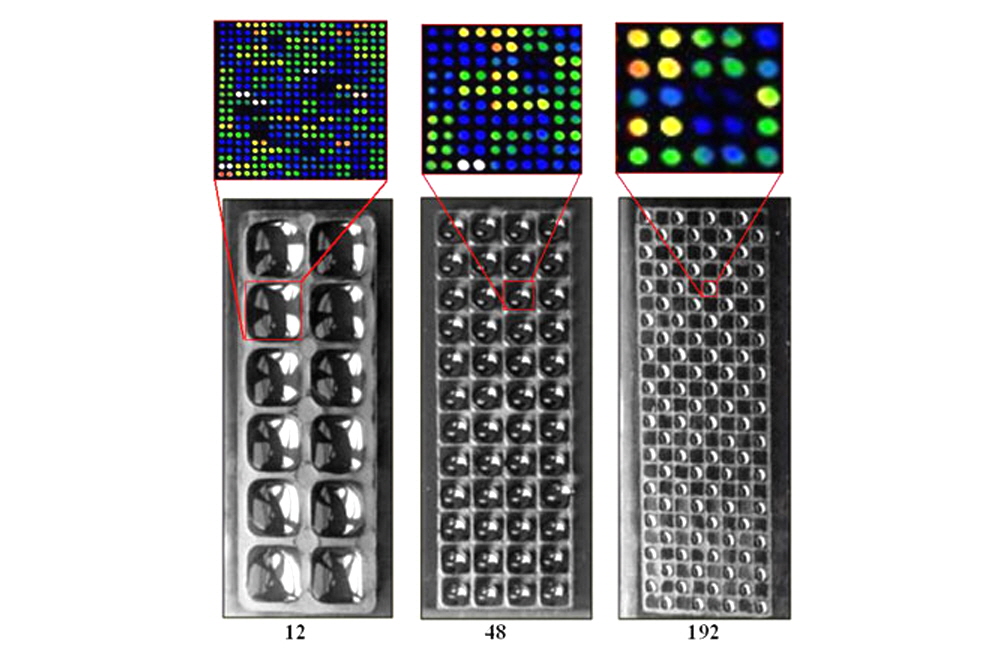

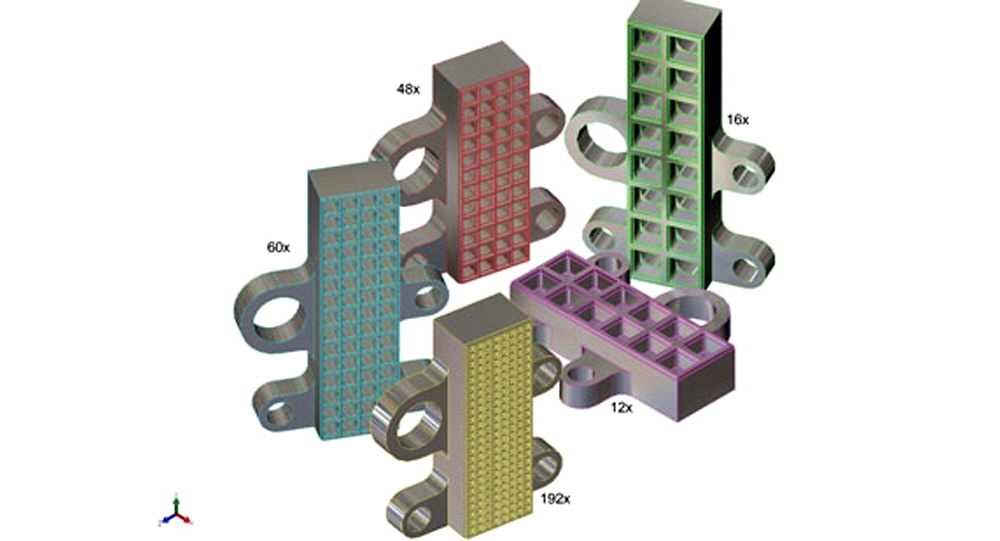

Arrayit Microarray Imprinter Stamps featuring 12, 16, 48, 60 and 192 well configurations.