SpotBot® Wash Buffer

Data Sheet

![]() Shop this product in our online store

Shop this product in our online store

Products - Microarray Buffers & Solutions - SpotBot® Wash Buffer to Enhance Microarray Pin Printing Cleaning and Improve Manufacturing Quality with SpotBot® Microarrayers

Arrayit offers the most advanced wash buffer available for microarray printing with SpotBot® robots and other robotic systems using Arrayit Pro, 946, Stealth and ChipMaker style pins. SpotBot® Wash Buffer is packaged in 1 liter bottles as a 1X solution that arrives pre-made and ready to use. Ideal for both peristaltic flow non-sonic wash stations and wash stations equipped with ultrasonic and megasonic transducers.

Table of Contents

- Introduction

- Quality Control

- Product Description

- Short Protocol

- Complete Protocol

- Technical Assistance

- Troubleshooting Tips

- Recommended Products

- Ordering Information

- Warranty

Introduction

Congratulations on taking a big step towards improving your microarray research. This booklet contains complete protocols outlining the steps required to use SpotBot® Wash Buffer.

Quality Control

Arrayit assures the performance of this Arrayit product. The highest levels of scientific research and innovation were used to develop this wash buffer.

Product Description

Arrayit provides the world’s most advanced wash buffer for microarray spotting pin use. Users will appreciate the following features:

- Advanced formula cleans pins at the molecular and atomic level

- Designed for all SpotBot® Personal Microarray Systems

- Compatible with any robot running Stealth or ChipMaker pins

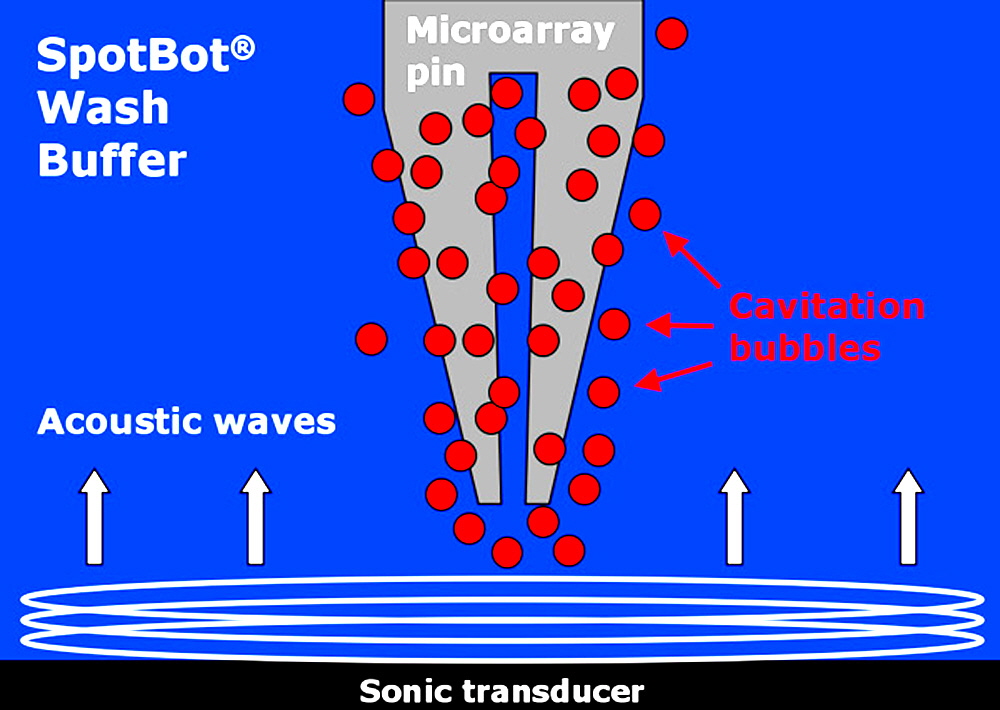

- Enhances pin cleaning in both non-sonic and sonic wash stations (Fig. 1)

- Reduces surface tension for enhanced cavitation

- Neutral pH prevents corrosion and pitting

- No residue between cleaning cycles prevents sample contamination

- No particulates or salts prevents pins clogging

- No strong solvents for increased user safety

- Water-based formulation safe to dispose

- Wide temperature range of use from 0-50°C

- 1 liter of 1X solution provides 16 hours of continuous SpotBot® operation

Figure 1. SpotBot® Wash Buffer enhances Micro Spotting Pin cleaning by reducing surface tension and enhancing cavitation for superior cleaning at the macroscopic, molecular, and atomic levels. Acoustic waves (arrows) produced by a sonic transducer in the wash station produce cavitation bubbles (red spheres) that deliver the cleaning force to pins during the wash/dry cycle of a microarray printing routine. SpotBot® Wash Buffer also improves pin cleaning in perstaltic flow wash stations.

Short Protocol (steps 1-3)

1. Transfer 1 Liter of SpotBot® Wash Buffer into the Wash Buffer Reservoir.

2. Perform the SpotBot® printing routine.

3. Replenish with SpotBot® Wash Buffer every 16 hours of SpotBot® operation.

Complete Protocol (steps 1-3)

1. Transfer 1 Liter of SpotBot® Wash Buffer into the Wash Buffer Reservoir. Remove the Wash Buffer Reservoir cap and transfer 1 Liter of SpotBot® Wash Buffer by slow pouring (Fig. 2), being careful not to spill over the sides of the Reservoir. After the liquid transfer step, make sure to replace the threaded Reservoir cap to prevent buffer evaporation. The Wash Buffer Reservoir flow line should be connected to the center port of the SpotBot® Wash Station via the peristaltic pump as described in the SpotBot® user manual. Once the peristaltic pump is powered on, make sure that Wash Buffer flows freely into the wash portion of the wash station.

2. Perform the SpotBot® printing routine. Once the Wash Buffer Reservoir is filled with SpotBot® Wash Buffer, power on the peristaltic pump and air compressor, and initiate a printing routine using the SpotApp software. New routines can be created and previous routines can be modified using SpocleGen software. Make sure wash buffer is flowing freely into the wash station. If wash buffer is not flowing, make sure the peristaltic pump is operating properly and that the feed lines from the Wash Buffer Reservoir to the pump and from the pump to the wash station are free of air bubbles. At the end of the print run, make sure to power down the pump, compressor, and SpotBot®.

3. Replenish with SpotBot® Wash Buffer every 16 hours of SpotBot® operation. Inspect the Wash Buffer level in the Wash Buffer Reservoir to make sure that it does not run dry. Replenish with SpotBot® Wash Buffer once the level reaches about one-quarter full. Running the Reservoir to dryness can introduce air bubbles into the system and impair buffer flow. Re-fill the Wash Buffer Reservoir by carefully pouring SpotBot® Wash Buffer from the bottle into the reservoir (Fig. 2). Fill the Reservoir completely and replace the threaded cap tightly to prevent buffer contamination. One liter (1,000 ml) of 1X SpotBot® Wash Buffer is sufficient for 16 hours of continuous operation. The use of SpotBot® Wash Buffer improves printing performance and consistency compared to distilled water and other traditional microarrayer wash buffers containing alcohols and detergents. SpotBot® Wash Buffer can be used at ambient temperatures ranging from 0-50°C for a wide range of microarray printing applications, including nucleic acids, proteins, and other molecules.

Figure 2. SpotBot® Wash Buffer is being used to re-fill the SpotBot® Wash Buffer Reservoir. This advanced 1X solution cleans microarray pins at the macroscopic, molecular and atomic levels for ultimate printing performance. For use in both peristaltic flow and sonic wash stations.

Technical Assistance

Please contact us if you have any comments, suggestions, or if you need technical assistance. By electronic mail: arrayit@arrayit.com (under the subject heading, please type Arrayit technical assistance). Please remember we want to hear about your successes!

Troubleshooting Tips

Poor buffer flow from Reservoir to Wash Station

- Make sure feed lines are free of air bubbles

- Make certain peristaltic pump is functioning properly

- Make sure Reservoir is filled with Wash Buffer

Poor pin cleaning

- Make sure sample volumes are 3-10 µl per well (384-well plate)

- Make certain Wash Buffer is flowing freely into the wash station

- Make sure air compressor to dry station is powered on and functioning

Recommended Products